Amazon Oil, a company based in the Brazilian state of Pará, will shortly be launching a new soap made with the oil of Brazil nuts (Bertholletia excelsa) and andiroba (Carapa guianensis Aubl.), enriched with fiber from the pits of açaí (Euterpe precatoria). Tests carried out by the company, which are now in the final stages, have shown that açaí pits—which contain the seed and surrounding fibers—function as an excellent skin exfoliant, a use already explored by São Paulo–based Beraca Ingredientes Naturais, owned by American group Clariant. Cosmetics company Natura, meanwhile, began producing two moisturizers in 2021, one for the face and one for the hands, that contains a bioactive extract from the açaí seed.

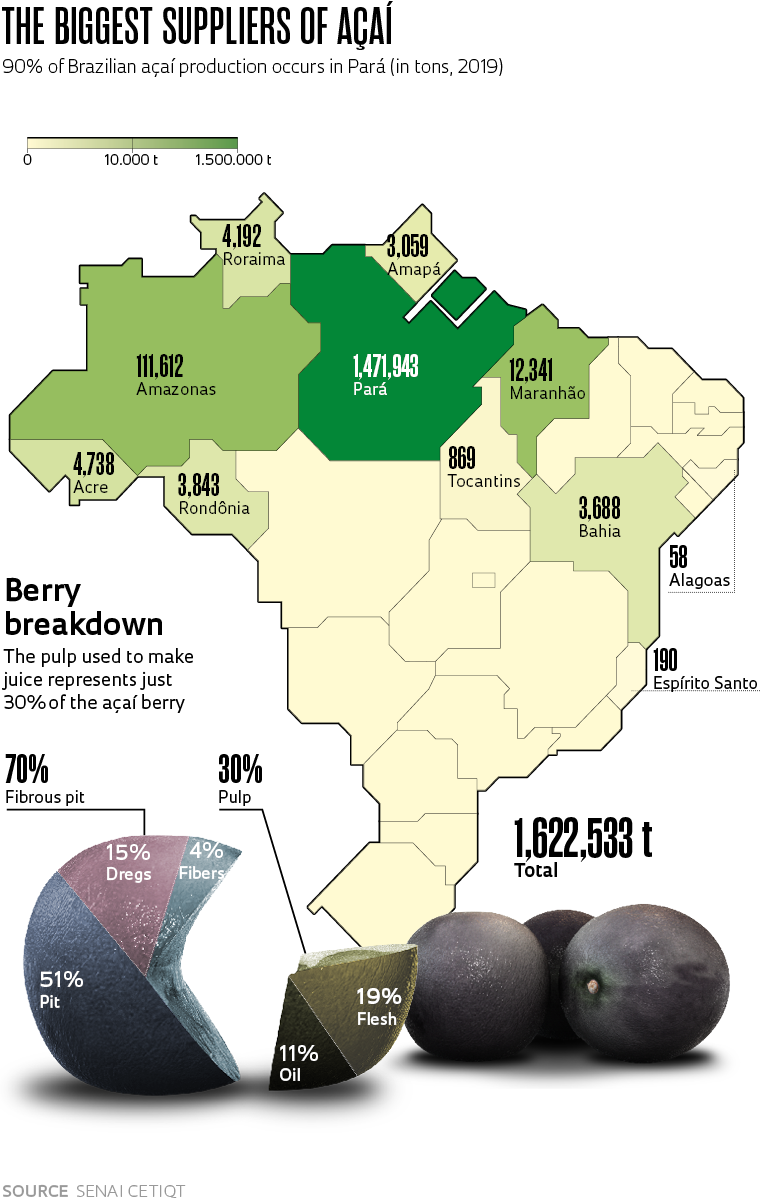

Cosmetics made of substances extracted from the açaí seed are the latest way to make use of an abundant raw material. According to the Technology Center for the Chemical and Textile Industries at the National Service for Industrial Training (SENAI-CETIQT), of an estimated production of 1.6 million tons (t) in 2019, around 60%, equivalent to 900,000 t, was discarded by mostly small producers, left by the roadside or in dumps in cities such as Belém in Pará and Manaus in Amazonas. The inhabitants of these regions are major consumers of juices, ice cream, and energy drinks made from açaí pulp. The pits, which represent roughly 70% of the mass of this small, purple, Amazonian fruit, are currently used commercially as a renewable energy source and a fertilizer, and on a smaller scale in handmade bracelets, earrings, and necklaces. Recent studies have suggested other potential uses that could be implemented in the near future, such as for making biodegradable plastic, food preservatives, and cellulose for paper.

The properties that underlie these potential new uses are becoming better known partly as a result of studies carried out by universities and research centers over the last 20 years—one possible use of açaí residue is the production of polymers for cranial prostheses, presented in 2012 by researchers from the University of Campinas (UNICAMP).

“Because it is short, the fiber from the pit does not need to be processed before it is incorporated into the soap and it is excellent at removing dead skin cells,” says Amazon Oil’s business director, Klaus Gutjahr, who is overseeing the tests at the Department of Chemistry, which started in 2021. “The açaí seed extract, in synergy with the pulp oil, helps neutralize free radicals [cellular waste],” adds Roseli Mello, head of research and development (R&D) at Natura.

“From 100 grams (g) of the seed, we can extract 45% pure, type I cellulose, similar to that produced from pine and eucalyptus wood,” says Silma de Sá Barros, a production engineer from the School of Engineering de Lorena at the University of São Paulo (EEL-USP) and lead author of an article describing these properties in the June 2021 issue of Research, Society and Development. For her PhD, she is developing polymeric compounds from agroindustry residues. In partnership with the Amazon Biotechnology Center (CBA) in Manaus, Barros is working on a project commissioned by a private company that remains anonymous for contractual reasons: cardboard boxes made of cellulose from açaí seeds collected from the street then cleaned and milled.

Eduardo Cesar / Revista Pesquisa FAPESPAçaí trees on an island near Belém in ParáEduardo Cesar / Revista Pesquisa FAPESP

“Since this waste is discarded almost year-round, there is no shortage of raw material,” she points out, recalling that her grandfather used to plant the seeds in their backyard when she was growing up in the interior of the state of Amazonas. The preliminary results of another study by the CBA and EEL-USP suggest that the ground pit could be used directly in the production of polymeric compounds.

At USP’s Luiz de Queiroz College of Agriculture (ESALQ) in Piracicaba, food scientist Priscilla Siqueira Melo found that the purified extract of dried and ground açaí seeds could potentially be used as a natural antioxidant in food and cosmetics. In an article published in the journal Industrial Crops & Products in March 2021, she described a low-cost method for extraction. “We were able to work at an ambient temperature of 25 degrees Celsius [ºC] and we were able to recover the ethanol used in the solution,” says the researcher. “The material left over from the extraction process could be used as a source of fiber in processed foods.”

Melo started studying açaí seeds during her PhD at ESALQ between 2012 and 2016. In search of agroindustrial residues that could be used as alternatives to synthetic antioxidants, she tested waste from coffee, oranges, cupuaçu, cajá, tomatoes, guava, and had the best results with grapes and açaí. Her article on the antioxidant potential of açaí seed extract, which she wrote based on her doctoral research, earned her the 2018 CAPES Natura Campus Award in the Biodiversity category.

At the Alunorte aluminum refinery in Barcarena, Pará, researchers from the Federal University of Pará (UFPA) and Norwegian group Hydro are assessing the technical and economic feasibility of using açaí pits as a fuel for the furnaces. “We initially want açaí pits to replace 5% of the coal in one of the boilers, which consumes approximately 30 t of fuel per hour,” says UFPA mechanical engineer Manoel Nogueira, who is leading the research. Tests indicate that every 1.5 t of coal would need to be replaced with 2.6 t of pits because of the lower calorific value, resulting in a consumption of 1,900 t per month or 22,800 t per year. The researchers determined that it would be possible to obtain 390,000 t per year from within a 160 km radius of the factory.

Eduardo Cesar / Revista Pesquisa FAPESPPolyurethane plastic made from açaí could be used in prosthesesEduardo Cesar / Revista Pesquisa FAPESP

Waste collection companies advised by the research team supply clean pits, which are stored in open-air piles 10 to 15 meters (m) high by 10 m in diameter before being moved to a covered area for two to three months, where they are constantly turned over to ensure they dry uniformly, with a reduction in humidity from 80% to 20%. Computer simulations indicated that the operating temperature of the boiler furnaces will need to be reduced from 950 ºC to 850 ºC. Tests of the furnaces will be conducted later this year.

“Açaí biomass offers an alternative source of renewable energy and unlike firewood, it does not require certification of origin,” points out Nogueira. But there is a drawback: the new fuel emits more carbon dioxide (CO2) than coal when burned. According to the UFPA scientist, 1 kg of coal emits 2.6 kg of CO2, while 1.7 kg of açaí residue—the amount needed to generate the same amount of energy—emits 3 kg of CO2. “But the pit’s carbon balance is close to neutral because burning it only releases CO2 absorbed by the açaí tree as it grew, while coal releases carbon that it did not absorb,” he points out. Based on these arguments, cement company Votorantim Cimentos has been using açaí instead of an oil residue called coke to fuel the furnaces at its factory in the city of Primavera, Pará, since 2017.

“Açaí pits are just one of the possibilities for making economic use of waste from the Amazon,” emphasizes Nogueira. In an article published in the journal Energies in October, he described the energy properties of the açaí pit and 65 other Amazonian agroforestry residues. The plant with the highest calorific value was pau-preto (Cenostigma tocantinum ducke), followed by tucumã pits (Astrocaryum aculeatum) and babassu bark (Orbignya speciosa). The açaí pits ranked 23rd.

Republish