In July, chemist Hernane Barud from the University of Araraquara (UNIARA) hopes to inaugurate the second bacterial cellulose membrane production unit at HB Biotech, of which he is a partner, in Santa Bárbara d’Oeste, in the state of São Paulo. The result of nearly R$1 million in investment from the Amas Investimentos group, which joined the company last year, the new factory is expected to increase monthly production to 7,000 sheets measuring 50 centimeters (cm) by 30 cm.

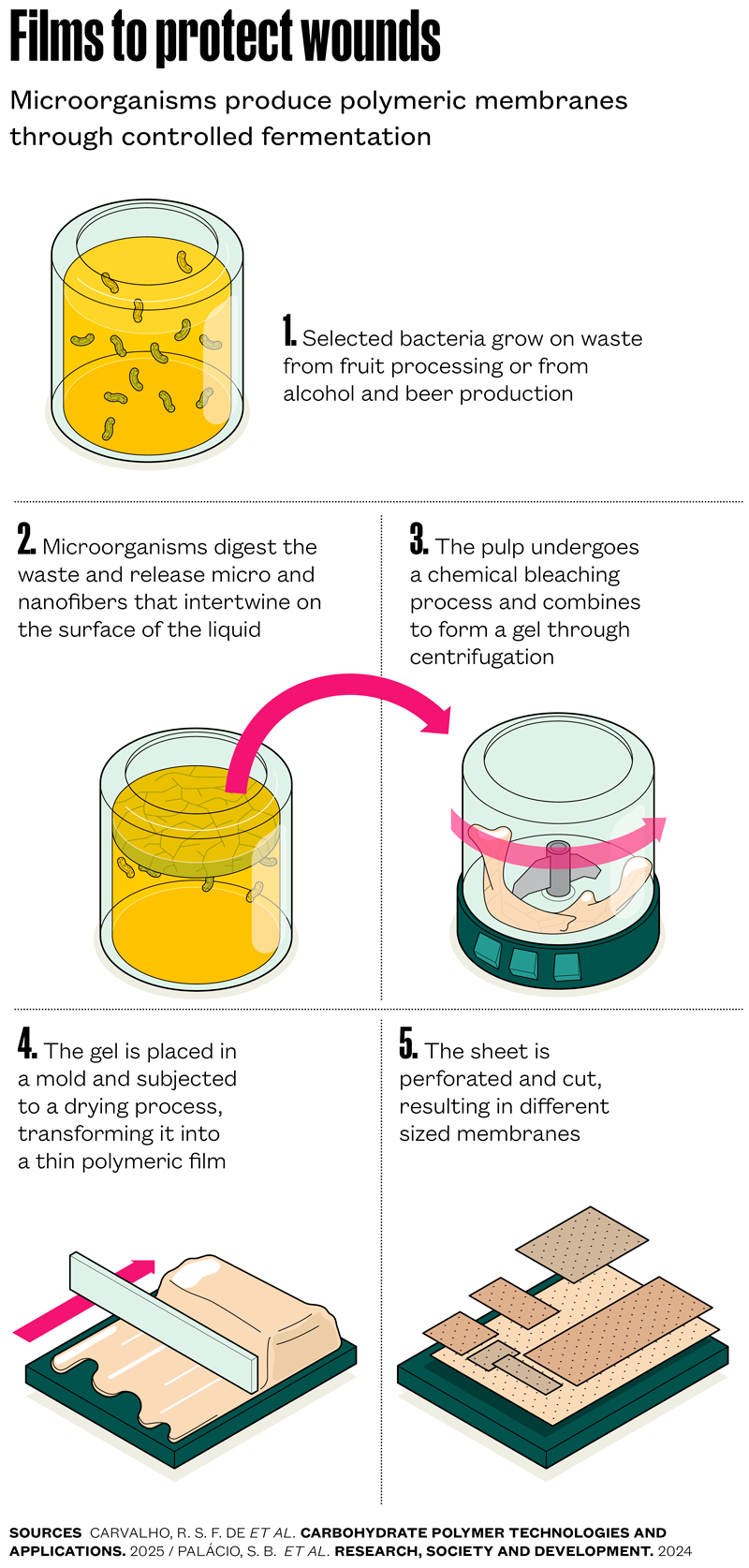

Flexible, biocompatible, and with high mechanical strength, the membranes are produced through controlled fermentation of selected strains of Komagataeibacter rhaeticus bacteria (see infographic opposite). They act as a support for skin regeneration and as a barrier against bacterial infection. For this reason, they aid the healing process of wounds, burns, and chronic sores, replacing similar products made from petroleum-derived compounds. Once the healing is complete, they detach on their own, like the dark scabs that naturally form over wounds. They also serve to filter liquids and as thickeners for foods or cosmetics, such as hair conditioners, among other applications.

“We will produce membranes for medical use as well as in gel and microfiber form for use as inputs, such as thickeners, for companies in the food and cosmetics sector,” says Barud. “It’s a growing market.” According to the US consulting firm Business Research Insights, this type of material accounted for a global market valued at US$480 million in 2024, with an estimated growth of 18% a year from 2025 to 2033.

Barud did his master’s and PhD about bacterial membranes at the Araraquara campus of São Paulo State University (UNESP) and was a partner of Nexfill, a manufacturer of this type of material until 2017, when it closed. From there, he helped found HB Biotech, currently located in the municipal business incubator in Araraquara, in the state of São Paulo.

With funding from FAPESP and collaboration with universities in the state of São Paulo, HB is investigating the possibilities of incorporating drugs into the membrane produced from Gluconacetobacter xylinum bacteria. One possibility is reinforcement with the antibiotic rifampicin for the treatment of skin infections, as reported in an article from April 2024 in the journal Cellulose. Another is the addition of calcium alginate, in search of a faster treatment for burns, as described in the July 2024 edition of the journal Acta Cirúrgica Brasileira.

Research at universities has helped to develop this area in Brazil. The production laboratory of the university start-up Polisa Biopolímeros, founded in 2015, operates in one of the buildings of the Experimental Sugarcane Research Station at the Rural Federal University of Pernambuco (UFRPE), on the Carpina campus, 45 kilometers from the state capital. Made from the bacterium G. hansenii, the membrane produced there, when ready, appears like a film, with a thickness ranging from 0.01 millimeters (mm) to 0.03 mm, 85% porosity, and a high capacity for water absorption and retention (190%), as outlined in March in the scientific journal Carbohydrate Polymer Technologies and Applications.

“We are already able to sell it, but we are refining the process for larger-scale production,” says pharmacist Girliane Regina da Silva. In 2022, the Brazilian Health Regulatory Agency (ANVISA) granted the company approval for two uses of the membrane, for the treatment of extracted nails, promoting the growth of a new one, and for external wounds of the urinary system. Both are classified as class I uses, which includes medical products that absorb fluids released by surface wounds and can be used for a few days.

Polisa exemplifies the path of many startups created in universities. There has been significant academic output. Since 1998, when production engineer Francisco Dutra, of UFRPE, found the G. hansenii bacterium in sugarcane fermentation tanks and discovered that it could produce cellulose membranes, dozens of articles have been published in both national and international scientific journals, demonstrating the membrane’s ability to promote the healing of wounds and arteries in mice, rabbits, dogs, and pigs. In human beings, it has been used to close perforated eardrums and aid in the healing of wounds, including those in people with diabetes, which are difficult to treat.

The company’s main difficulty is scaling up production. “To grow, we need investment, which we don’t have,” says surgeon José Lamartine de Andrade Aguiar, a retired professor from the Federal University of Pernambuco (UFPE) and one of the company’s seven partners. Until now, according to him, talks with potential investors have been unsuccessful. The company is mainly supported by research project funding from state or federal agencies, as well as investments from the partners themselves, all of whom have other jobs.

The membrane—a polymer, essentially formed by glucose molecules—has a long history. In 1886, while studying the fermentation of acetic acid, the main component of vinegar, by the bacterium G. xylinum, British chemist Adrian John Brown (1852–1919) was the first to identify this type of gelatinous film, made of pure cellulose, with the same chemical structure of cellulose synthesized by plants. In the following years, other bacteria such as Azotobacter, Bacillus, Lactobacillus, and Zooglea revealed their capacity to produce this material on a large scale.

Culture media rich in glucose, phosphorous, nitrogen, and carbon, such as coffee husks, wheat straw, fruit bagasse (like citrus at HB Biotech), and waste from beer or cheese production, and sugarcane processing (molasses, like at Polisa), serve as nutrients for the bacteria. “The bacteria secrete the polymer through pores after feeding on the sugars in the molasses,” says biologist Layla Mahnke, from Polisa, while showing the vials in which the bacteria are cultivated.

HB BiotechBiocellulose from HB Biotech used in the production of the membraneHB Biotech

Equivalence with synthetic materials

The membranes from Brazilian manufacturers—including Bionext, Fibrocel, Innovatecs, and Vuelo—as well as those produced in the USA, Canada, Sweden, the UK, Germany, France, and Japan have promoted faster and cheaper healing of wounds and burns than most synthetic equivalents, according to an article by researchers from the Aeronautics Chemical-Pharmaceutical Laboratory and Polisa, published in February 2024 in Research, Society and Development. However, they faced competition from membranes containing xanthan gum, ethanol, and acetic acid, or made with some synthetic products, such as polyurethane and rayon.

In another study, a group from UNESP’s Botucatu campus found that a membrane produced by the bacterium Acetobacter xylinum at Innovatecs, in São Carlos, São Paulo State, stimulates the production of interleukin-10 (IL-10), a protein with anti-inflammatory properties. The results were described in an article published in February 2022 in the journal Materials Letters.

Despite being a promising material, there are still unresolved issues. Researchers from ITMO University (formerly known as the Saint Petersburg National Research University of Information Technologies, Mechanics and Optics), in Russia, have warned, however, about the need for further studies on the long-term biocompatibility and potential undesired bodily reactions, as well as standardized protocols for testing the effectiveness of bacterial cellulose membranes, as discussed in an article set to be published in June in Carbohydrate Polymers.

“One of the big challenges is scaling up production, since it is a fermentation process,” observes chemist Guilhermo Castro, of the Federal University of ABC (UFABC), who participates in research with HB Biotech. With his team, he is searching for new species of bacteria capable of producing cellulose membranes and is researching the possibilities of incorporating antitumor drugs into the material. “To avoid competing with large companies, we should focus on specific applications, such as the use of the membrane for treating burns or of the gel for some types of brain cancer,” he suggests.

The story above was published with the title “Skin doubles” in issue 352 of April/2025.

Projects

1. Biocellulose-based cell culture platform (n° 18/25512-8); Grant Mechanism Regular Research Grant; Principal Investigator Hernane da Silva Barud (UNIARA); Investment R$154,139.06.

2. Cultivation of mesenchymal stem cells from human bone marrow on Nanoskin scaffolds for ocular surface reconstruction (n° 15/10727-0); Grant Mechanism Regular Research Grant; Principal Investigator Silvana Artioli Schellini (UNESP); Investment R$46,418.33.

Scientific articles

BULKINA, A. & PRILEPSKII, A. Bacterial cellulose: Is it really a promising biomedical material? Carbohydrate Polymers. Vol. 357, 123427. June 1, 2025.

CARVALHO, R. S. F. de et al. Bacterial cellulose hydrogel produced by Gluconacetobacter hansenii using sugarcane molasses as medium: Physicochemical characterization for wound healing applications. Carbohydrate Polymer Technologies and Applications. Vol. 9, 100632. Mar. 2025.

HATA VIVEIROS, M. M. et al. Physical, functional and biochemical features of Nanoskin (R) bacterial cellulose scaffold as a potential carrier for cell transference. Materials Letters. Vol. 308, no. A, 131109. Feb. 1, 2022.

MONTEIRO DOS SANTOS, K. et al. Curativo regenerativo de celulose bacteriana para lesões por ressecção tumoral. Revista de Enfermagem Atual In Derme. Vol. 99, no. 1, e025025. Feb. 20, 2025.

MUNHOZ, L. L. de S. et al. Bacterial nanocellulose/calcium alginate hydrogel for the treatment of burns. Acta Cirúrgica Brasileira. Vol. 39, p. 1. 2024.

PALÁCIO, S. B. et al. Application of wound dressings based on bacterial cellulose in the healing of chronic and complex wounds: Trends and perspectives. Research, Society and Development. Vol. 13, no. 2. e1813244920. Feb. 6, 2024.

SILVA, J. G. M. da et al. Melatonin and bacterial cellulose regulate the expression of inflammatory cytokines, VEGF, PCNA, and collagen in cutaneous wound healing in diabetic rats. Polymers. Vol. 16, no. 18. 2611. Sept. 15, 2024.

SILVEIRA, F. C. A. et al. Tratamento do tímpano perfurado com enxerto de celulose bacteriana: Ensaio clínico controlado e randomizado. Brazilian Journal of Otorhinolaryngology. Vol. 82, pp. 203–208. Sept. 8, 2015.

YAMADA, C. et al. Bacterial cellulose-based scaffold: Synthesis and surface modification for sustained rifampicin release for topic skin infections treatment. Cellulose. Vol. 31, pp. 4441–60. Apr. 14, 2024.

Republish