Imagine a cell phone with a battery that lasts for years and doesn’t need to be plugged in to recharge. Or a drone capable of flying indefinitely over Amazonia, registering deforestation and illegal mining hotspots. Situations such as these may become a reality in time, with the start of commercial production of new energy storage systems that use radioactive material to generate an uninterrupted electricity supply for dozens or hundreds of years.

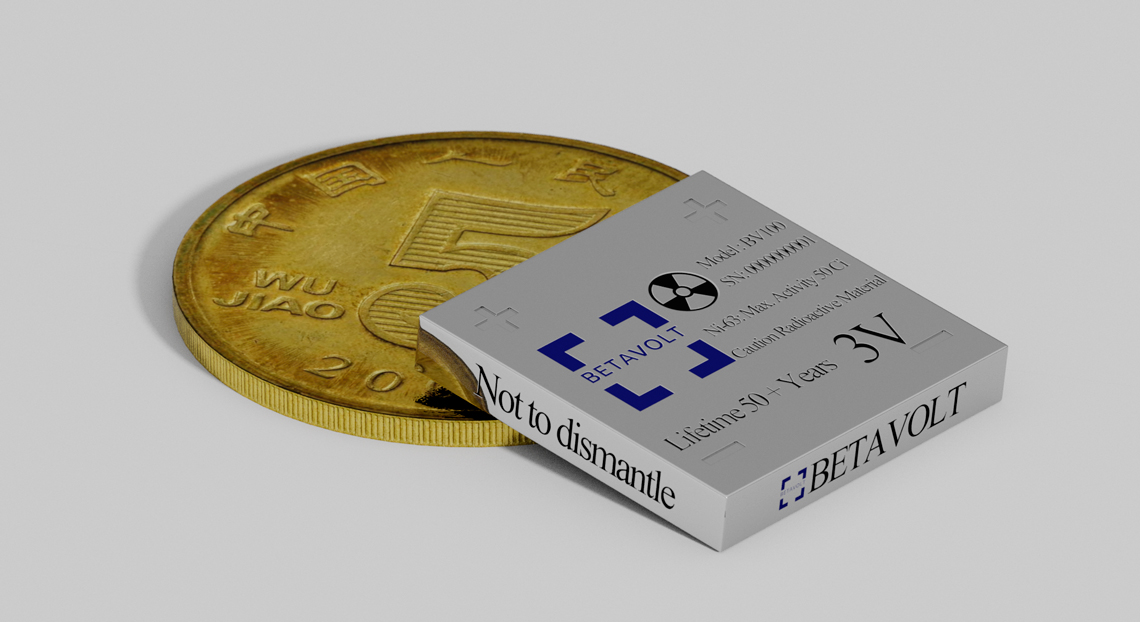

One of these innovations was revealed at the beginning of this year by Chinese start-up Betavolt, which developed a nuclear battery that will be able to generate energy for 50 years without recharging. The device, with 100 microwatts (µW) of power and 3 volts (V) of electrical voltage, is still a pilot project, and operates based on conversion of energy released by the decay of radioactive nickel isotopes (Ni-63). Betavolt plans to launch a more powerful version of the battery, with power of 1 watt (W), in 2025. With modular function, it can be deployed in series to power drones or cell phones.

Brazil has ongoing studies in the area. At the end of 2023, a team from the Institite of Energy and Nuclear Research (IPEN), based in São Paulo, presented the first prototype of a thermoelectric nuclear battery made in the country. The operating principle of the device, also known as a radioisotope thermoelectric generator (RTG), is different from the Betavolt system: an electrical current is produced by converting the heat generated by disintegration of an americium isotope (Am-241) (see infographic). In the Chinese module, beta particles (electrons) are transformed into electrical current by means of a specific converter system.

The process of radioactive decay or disintegration takes place when the unstable nucleus of a chemical element is transformed into the nucleus of another in a lower energy state. The process releases electromagnetic radiation and can emit particles. This phenomenon is characterized by the half-life, which is the time required for half the radioactive isotope atoms in a given sample to disintegrate.

“During development, we needed to design a thermoelectric generator module to convert thermal energy into electricity,” explains chemical engineer and doctor of nuclear technology Carlos Alberto Zeituni, manager of the IPEN Radiation Technology Center (CETER), one of the units involved in the project; the other is the Nuclear Engineering Center (CEENG).

The main advantage of nuclear batteries is the potential to hold charge over a long period of time. “A conventional chemical battery lasts for five years, while a lithium one may have a lifespan of 10. Nuclear batteries may last for 50 or 100 years or more, depending on the radioactive material used. We estimate that ours will last for more than 200 years,” says Zeituni. The research, commenced two years ago, is being funded by a national corporation interested in commercializing the technology. For contractual reasons, its name cannot be revealed.

The IPEN researchers used 11 sources of americium, originally used in plate-thickness measuring devices. To eliminate the risk of radioactive material leakage, the sources were stacked and encased in an aluminum tube. “The starting parameter of any nuclear project has to be safety. The battery will only be sold when there are guarantees that the risk of leakage is nonexistent,” explains mechanical engineer Eduardo Lustosa Cabral, a CEENG researcher involved in the project.

Studies into nuclear batteries began at the beginning of the last century, and to date there has been no commercial manufacture. They are produced in a limited manner primarily by the governments of countries with a mastery of nuclear technology, such as the US, Russia, France, China, and the UK.

Betavolt The Betavolt battery measures 15 millimeters (mm) in length, by 15 mm width, and 5 mm thicknessBetavolt

The technology is used in devices deployed to sites of difficult access, such as desert-island lighthouses, caves, and laboratories in the Arctic and Antarctic. In the 1970s, it came to be used in pacemakers—devices used to monitor and regulate heartbeats—implanted into over 300 people. “There were no reports of leakage or failure,” says chemical engineer and doctor of nuclear technology Maria Alice Morato Ribeiro, a researcher at CEENG and group leader. The NASA Rovers and Voyager probe, sent into space in 1977, also use these batteries. The module developed at IPEN will be used for applications in remote locations.

“The use of this technology is constrained by the fabrication costs, availability of raw material, and production difficulties,” says Ribeiro. Great care needs to be taken to prevent leakages during fabrication and operation of devices. Another challenge is the fact that the whole of the electrical unit is exposed to radiation, which may damage the system.

Tough competition

For physicist Hudson Zanin, of the School of Electrical Engineering at the University of Campinas (UNICAMP) and coordinator of research aimed at developing a sodium-based battery (see Pesquisa FAPESP issue no. 329), the work done at IPEN is promising but will have to overcome challenges to arrive at a marketable product.

“At a time of discussion about how to transform into a 100% electric society based on renewable energy sources replacing fossil fuels, energy storage is a key technology. The development of more different types of batteries, including this one at IPEN, is important,” he goes on.

“The long periods of nuclear battery operation without charging give them a significant edge, but they need to be developed to increase the output voltage,” remarks the UNICAMP physician. “Additionally,” he points out, “they will face tough competition from other advanced, cheaper, and established technologies, such as lithium-iron-phosphate (LFP) and nickel-cobalt-manganese (NCM) batteries.”

Republish