Sitting at his lab bench, textile engineer André Correa Marcilio connects the ends of two cotton threads to a small LED, which immediately lights up. The secret? Conductive carbon and silver particles infused in the specially designed threads. Marcilio, a director at specialty fabrics manufacturer AG Têxtil, based in Americana, inland São Paulo State, plans to use these conductive cotton threads to create a throw pillow that doubles as a remote control. It will feature touch-sensitive embroidered buttons that can be used, for example, to control a smart TV.

Functional threads are an example of a growing field in textile engineering known as wearable electronics. The company is now working to develop and produce a range of flexible fabrics or films that can conduct electricity like conventional copper wires. These materials, which are harmless to wearers, are already being used in clothing, footwear, and accessories, providing a host of new functionalities. For instance, Levi’s and Google have designed a jacket that can control a user’s smartphone via a device with a Bluetooth antenna and battery, placed in a removable snap tag. The product is slated to launch this fall, priced at US$350.

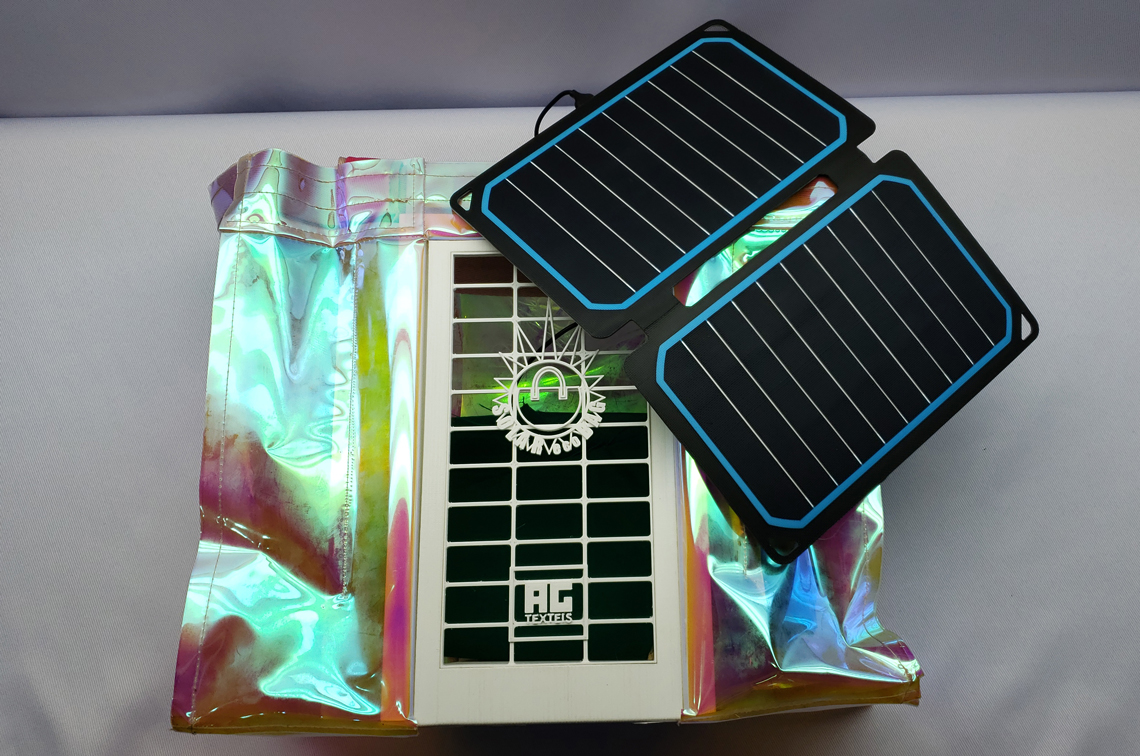

AG Têxtil produces a beach bag with a battery and a Bluetooth antenna that can connect to a mobile phone and stream music through a built-in speaker. Fabrics that can generate and store electricity for charging smartphones, and sensors for measuring heart rate and blood pressure, are some of the innovations expected to reach the market in the near future.

Another example hails from the Center for Semiconductor Components and Nanotechnology at the University of Campinas (CCSNano-UNICAMP): an insole with a flexible heating insert made of nanographite combined with conductive silicone, designed for boots worn by workers in low-temperature environments, such as cold rooms. The device is currently being licensed to a company that intends to manufacture it on a commercial scale.

Léo Ramos Chaves / Revista Pesquisa FAPESPUNICAMP’s prototype boot with a heating insoleLéo Ramos Chaves / Revista Pesquisa FAPESP

Physicist Stanislav Moshkalev, who led the research team, plans to use only Brazilian-made components to lower costs compared to imported alternatives. Even when overlaid, the films can be folded without tearing, exhibiting similar conductive properties to graphene, a more expensive material, as detailed in an article published in April 2023 in Frontiers in Nanotechnology.

To make the insole, the film is covered on one side with synthetic foam and on the other with a material known as non-woven fabric, made of fibers and polymers. A copper wire conducts electricity to the film from rechargeable batteries in an external pocket on the boot’s shaft. This film can maintain a temperature of approximately 30 degrees Celsius for up to seven hours. There is no risk of wearers getting an electric shock since the device operates at a safe voltage of 12 volts (V).

One of the challenges in developing the device was connecting the battery to the film. “Silicone wouldn’t hold the solder between the film connectors and the copper wires for long. We tried gluing and sewing it, but it kept coming off,” explains chemist Silvia Nista, a member of the UNICAMP research group. The solution the researchers devised was to develop a new, as-of-yet-undisclosed soldering method that is currently patent-pending. “Films made with the new soldering method could be used to heat gloves and motorcycle helmets or even in therapeutic treatments,” says Moshkalev.

AG Têxtil developed its conductive threads in collaboration with the Renato Archer Information Technology Center (CTI) in Campinas, São Paulo, with support from the FAPESP Innovative Research in Small Businesses (PIPE) program. Marcilio has previously attempted to sell the special threads to various manufacturers, but potential buyers were only interested in finished products. “One company wanted hundreds of bags with illuminating logos; another was seeking car seats that could be adjusted using touch-sensitive embroidered buttons; and a third wanted bed linens with sensors to monitor people’s sleep,” he says.

Jacquard GoogleA Levi’s jacket with a smartphone pocket and a removable wrist device for controlling mobile devicesJacquard Google

However, we would never be able to meet their requests. “The biggest challenge is scaling up production to fulfill high-volume orders,” notes chemist Renata Nome, who developed the conductive threads. Following market research as part of an entrepreneurship course sponsored by FAPESP, she and Marcilio opted to produce bags and throw pillows that could accommodate these components.

Jacquard GoogleRemovable device on the cuff of the Levi’s jacketJacquard Google

At the Federal University of Vale do São Francisco’s (UNIVASF) Juazeiro campus in Bahia, electronic engineer Helinando Pequeno de Oliveira is developing fabrics and films that can generate their own power, eliminating the need for batteries.

Since 2019, Oliveira and his team have been building prototype components made of fabrics and films that can harness mechanical energy, such as body movements, to generate electricity. Known as triboelectric nanogenerators, or TENG for short, these devices convert electrostatic energy (generated by static electric charges built up on the surfaces of objects or the human body) into electric current through the friction generated by constant contact between two surfaces.

Typically, one of the surfaces is a polymer and the other is a material capable of exchanging charges between them (one becomes positively charged and the other negatively charged). The first prototypes were developed by Chinese researchers in 2012.

The UNIVASF group has developed a flexible triboelectric film made from PVA, a synthetic polymer, combined with fibroin, a protein extracted from silk. In one experiment, the film generated electricity by being rubbed against a transparent silicone film — a unique feature compared to alternative devices, which typically require the second layer to be metal.

“We achieved a material with nearly 70% transparency, high conductivity, and the ability to generate a voltage of up to 172 V. This can power up to 56 LEDs or small electronic devices,” says Oliveira, who reported on the innovation in a January 2023 article published in Nano Energy. In the future, he explains, the primary applications for nanogenerators would be in footwear, as walking provides the continuous motion needed to generate enough electricity to charge a mobile device.

Generating electricity is only one part of the equation; it also needs to be stored. To achieve this, Oliveira created conductive and chemically modified cotton threads to serve as both electrodes and supercapacitors, or devices that can store electricity — in this instance the electricity generated by body movements.

After receiving a double layer of carbon nanotubes and graphene, coated with a plastic polymer, the cotton threads gained the ability to generate as well as store electricity. In one application, described in an article published in April 2018 in ACS Applied Materials & Interfaces, a pair of threads, one carrying a positive charge and the other a negative charge, separated by a hydrogel adhesive, were stitched into a glove, giving it heating as well as antibacterial functionality.

“The polymer coating enveloping the threads stores an electric charge that can last for two to six minutes,” Oliveira explains. He is now looking to develop devices capable of storing longer charges. As this technology evolves, applications will extend beyond apparel. “This technology could be used to make pacemakers powered by body movements, eliminating the need for battery replacements,” Oliveira envisions.

With time, clothing or even the skin itself may evolve into platforms for health monitoring devices. At the São Carlos Institute of Physics of the University of São Paulo (IFSC-USP), physicist Osvaldo Oliveira Júnior has developed a biosensor that can analyze sweat to determine urea levels in the body, an important parameter when monitoring kidney function. The novel sensor is described in a paper in the March edition of Biosensors and Bioelectronics.

AG Têxtil A beach bag from AG Têxtil with a battery, Bluetooth antenna, and loudspeaker that can connect to a mobile device and play musicAG Têxtil

The biosensor patch consists of a layer of PVA with flexible carbon electrodes. It combines a urea sensor with a pH sensor, which measures the acidity or alkalinity of substances. This dual-sensor approach enables urea levels to be determined based on the acidity detected in sweat. “As acidity levels can vary from one individual to another, the second sensor corrects for these differences, transmitting more accurate data to a computer over a — currently hardwired — connection,” explains Oliveira Júnior. The next step in the development of this biosensor would be enabling it to transmit data wirelessly.

According to Oliveira Júnior, international research points to three major applications for wearable devices. “One of them is healthcare, with sensors being developed to monitor health parameters through sweat and other fluids.” Two decades ago, his team explored ways to add new functionality to fabrics, including a prototype featuring silver nanoparticles with antibacterial properties and a prototype with odor-resistant properties.

Other applications, as featured in this article, include electronic devices integrated into clothing, shoes, and accessories that can generate and store electricity, and wearables that can regulate body temperature in extremely cold or hot environments, ideally without the need for conventional batteries.

In June, Nike unveiled a sports jacket featuring an automatic venting system that adapts to the wearer’s body. According to Nike’s website, the jacket has small moisture-reactive vents that activate when sweat builds up on the skin, enhancing airflow. As the body cools and the sweat dries, the vents close. This active response is achieved through a film stitched into the vents, which contracts or expands upon contact with sweat, helping runners and athletes regulate body temperature in real time.

Project

Electrically conductive filaments incorporating nanomaterials and applications in textile electronics (nº 19/10547-3); Grant Mechanism Innovative Research in Small Businesses (PIPE); Principal Investigator Renata Cristiano Nome (AG Têxtil); Investment R$519,136.38.

Scientific articles

NISTA, S. V. G. et al. Flexible highly conductive films based on expanded graphite/polymer nanocomposites. Frontiers in Nanotechnology. apr. 2023.

CANDIDO, I. C. M. et al. PVA-silk fibroin bio-based triboelectric nanogenerator. Nano Energy. v. 105, 108035. jan. 2023.

LIMA, M. A. P. et al. Multifunctional wearable electronic textiles using cotton fibers with polypyrrole and carbon nanotubes. ACS Applied Materials & Interfaces. v. 10, n. 16. apr. 2018.

IBÁÑEZ-REDÍN, G. et al. Wearable potentiometric biosensor for analysis of urea in sweat. Biosensors & Bioeletronics. v. 223, p. 114994. mar. 2023.