Léo Ramos Chaves

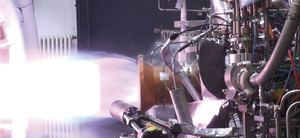

Chemical reaction between a drop of hydrogen peroxide and the fuel composed of ethanol, ethanolamine and copper salts. The temperature reaches 900°C and the gases can propel a satellite into orbit. The experiment was carried out at INPE, in Cachoeira Paulista.Léo Ramos ChavesEmploying a renewable fuel for rockets and satellites that is less toxic, less harmful to human health and more environmentally friendly, is the objective of two Brazilian research groups, one at the National Institute for Space Research (INPE) and the other at the Aeronautics and Space Institute (IAE), the research branch of the Aerospace Science and Technology Department (DCTA) of the Brazilian Air Force. At INPE, scientists in the Associated Laboratory for Combustion and Propulsion (LCP), in the city of Cachoeira Paulista, São Paulo State, developed a new space fuel, also called propellant, whose ingredients include ethanol and hydrogen peroxide. One distinguishing feature of the fuel is that it does not need an ignition source, such as a spark, to combust and make the engine work. At IAE, in São José dos Campos, the research was carried out together with the German Aerospace Center (DLR), whose focus is the development of an engine for vehicles to launch satellites that can run on ethanol and liquid oxygen.

The main propellants used in rockets and satellites are hydrazine, which is the fuel, and dinitrogen tetroxide, the substance that causes the burning reaction. These substances perform well in thrusters, but have disadvantages. In addition to being expensive, hydrazine and its derivatives are carcinogenic, and therefore require great care in handling. Dinitrogen tetroxide, however, can be fatal after a few minutes of exposure, in the event of leakage or poor handling.

The search for an alternative space fuel that is less harmful to human health and the environment is not exclusive to Brazilian institutions. “Space agencies from several countries—including NASA—are conducting research on this topic,” says Carlos Alberto Gurgel Veras, director of the Brazilian Space Agency’s (AEB) Division of Satellites, Applications and Development. “Since Brazil has not mastered the production cycle for traditional propellants used in rocket engines, developing an alternative fuel would be a significant advance for the industry,” says Gurgel. Having a readily available fuel in Brazil, largely renewable and at a low price, is part of the technological development package to be achieved by the Brazilian aerospace industry. For more than 20 years, INPE has developed small satellites to collect environmental data and, together with China, to perform remote sensing with the goal of capturing images of Earth’s surface. All of them were launched by foreign rockets.

Brazil has solid fuel propulsion engine technology for the small rockets used in scientific and technological experiments. “Our chief objective is to master the technologies needed to develop a liquid-propellant rocket engine. In order to launch large satellites, we have to use this type of propulsion,” says metallurgical engineer Daniel Soares de Almeida, IAE project manager.

Chemical engineer Thais Maia Araujo, a specialist in rocket fuels and a professor in the aerospace engineering course at the Federal University of the ABC (UFABC) in São Bernardo do Campo, São Paulo State, feels that it is important for Brazil to work on developing a renewable propellant for the industry. “The fuel being developed at INPE, in addition to being safer and easier to handle, is cheaper than traditional propellants and has the appeal of sustainability. Ethanol is a renewable fuel widely available in Brazil,“ she says.

INPE’s effort to develop an ethanol-based space propellant began three years ago. Led by industrial chemist Ricardo Vieira, head of the LCP, the research team included PhD candidate Leandro José Maschio, from the Engineering School of Lorena, University of São Paulo (USP). Although it can be used in rockets, the new fuel is intended mainly for satellites. “Our propellant would be better for what are known as apogee engines, used to transfer a satellite into its orbit,” explains Vieira. After being launched into space, satellites need to position themselves in the correct orbit and the displacement is performed by thrusters on the satellite itself.

IAE

Model of the L75 rocket developed at IAE, which uses ethanol and liquid oxygenIAEStrategic addition

The new propellant, according to Vieira, has an efficiency close to that of traditional fuels. “The composition contains about 30% ethanol, 60% ethanolamine [an organic compound resulting from the reaction between ethylene oxide and ammonia] and 10% copper salts,” says the head of the LCP. “The addition of ethanol was purely strategic, since Brazil is a large alcohol producer. However, during development, we found that ethanol increased engine performance, reduced fuel ignition time and reduced fuel price.”

To make the engine work, the mixture of ethanol, ethanolamine, and copper salts reacts with hydrogen peroxide. “It acts like an oxidant by providing oxygen for the reaction, as oxygen does not exist in space. Hydrogen peroxide decomposes when it comes into contact with the fuel. The reaction is catalyzed by the copper, and generates heat—around 900oC—which ignites the ethanol from the ethanolamine,” Vieira explains. Large volumes of gases are produced, and this gives the desired propulsion. Spontaneous combustion occurs when the chemical components come into contact. Mixing is controlled by software and, if possible, by ground-based technicians.

Another advantage is the low cost. INPE imports hydrazine for about R$700/kilogram (kg) and nitrogen tetroxide for R$1,300/kg. “We estimate that the ethanol- and ethanolamine-based fuel will cost approximately R$35/kg and hydrogen peroxide will cost R$15/kg. Since a satellite carries more than 100 kg of propellant, the savings is great in this aspect, but relatively small in relation to the final cost of the system,” emphasizes Vieira. “But, if we take into account future use in rocket launcher stages, the savings could become quite significant.”

In order to demonstrate that the propellant is feasible and works, INPE designed and successfully tested a thruster employing the new fuel in its laboratory. According to Vieira, the next step would be to manufacture a larger engine and perform tests in a vacuum, simulating conditions in space. “According to the researcher, AEB has already shown interest in financing the manufacture and testing of an engine using ethanol-based fuel. “If we plan the project well and find the right partners, I believe the ethanol-ethanolamine engine could be ready in 10 years,” says Gurgel.

At IAE, the team in charge of designing an ethanol-fueled rocket engine achieved an important milestone by conducting successful tests. The tests were carried out in late 2016 in the laboratories of the DLR Space Propulsion Institute, in Lampoldshausen, Germany, which is working with IAE on the project. The L75 engine employs liquid oxygen and better quality ethanol than that sold for cars. Its name is a reference to the liquid fuel (L) and engine thrust of 75 kilonewtons (kN)–enough to lift a 7.5-metric-ton truck off the ground.

IAE

Test bench for IAE engines, in São José dos CamposIAEDouble the performance

The design of the L75 motor began at IAE in 2008, and five years later DLR technicians and scientists also began working on the project. The tests carried out this year in Germany assessed two fuel injection heads based on different concepts, developed simultaneously by IAE and DLR researchers. The objective of the evaluations was to determine combustion performance parameters and define the best propulsion technology. The two heads differ in the way the fuel is sprayed into the combustion chamber and mixed with oxygen.

“In this first series of tests, the main objectives were achieved,” said German aerospace engineer Lysan Pfützenreuter, project manager at DLR. “We achieved 42 successful ignitions during a period of 20 days. We were able to closely analyze the behavior and stability of the system during ignition and startup in the thrust chamber, among other things.” Preliminary analyses of the results showed that the two heads had similar performance.

Cooperation between IAE and the German DLR dates back to 1960, when the Barreira do Inferno Launch Center (CLBI), in Rio Grande do Norte State, was used to launch rockets related to scientific experiments for the Max Planck Institute for Extraterrestrial Physics in Germany. Around the year 2000, the cooperation was strengthened through an agreement to jointly develop a two-stage probe rocket, which was named VSB-30 and had its qualifying flight in 2004. More recently, in 2012, the Germans used a Brazilian suborbital rocket, the VS-40M, to carry the Shefex II (Sharp Edge Flight Experiment) experiment into space. Its goal was to develop key technologies, such as heat protection systems for spaceships with the ability to go into space and return to Earth, which requires withstanding the harsh conditions of re-entry into the atmosphere.

According to IAE, it will take about 10 years for the L75 engine to undertake its first qualifying flight, which is when all thruster parameters will be tested. The project was divided into four stages (feasibility study, preliminary design, detailed design and qualification) and is currently concluding the second stage. “The next step is to prepare the detailed design, which should take place from 2017 to 2021. Then, from 2022 to 2026, the L75 engine will enter the qualifying stage, and after that period it will undertake its first flights,” says Almeida.

DLR

Test of L75 engine carried out in 2016 in the German Space Center, together with Brazilian researchersDLRAlternatives around the world

NASA and ESA have propellant projects that could be advantageous replacements for hydrazine

Before the end of 2017, the North American Space Agency (NASA) plans to test a propellant that would be an alternative to the traditional rocket fuel hydrazine. Named the AF-M315E, it is an ammonium-nitrate-based liquid, a substance that is easier to obtain and less dangerous to handle than hydrazine. Started in 2012, NASA’s Green Propellant Infusion Mission program is partnering with the U.S. Air Force Research Laboratory, responsible for developing the fuel, and U.S. companies Aerojet Rocketdyne, which designed the thruster, and Ball Aerospace & Technology, which is managing the project. According to Ball, the new propellant performs almost 50% better than systems using hydrazine. With this, the same tank can carry a larger amount of AF-M315E, in theory extending the duration of space missions.

The new propellant is considered green by the Americans because it has environmental benefits, such as being less toxic than hydrazine. It will be used to maneuver a small satellite in space. Over a period of 13 months, changes will be made in the altitude and orbital attitude of the satellite to demonstrate the feasibility of the propulsion system.

The European Space Agency (ESA) also has green fuel candidates. One project is the monopropellant LMP-103S, developed by the Swedish company ECAPS, ESA’s partner. The main ingredient is a substance known as ammonium dinitramide (ADN), obtained using chemical processes whose wastes are less harmful to the environment than those of other space propellants. Its formulation also includes methanol, ammonia and water.

ECAPS says that the new fuel is more stable, more efficient and safer to handle than hydrazine. It allows reuse of propulsion system components designed to use hydrazine.

Project

Study of hypergolic ignition of hydrogen peroxide and ethanol through a catalyst (No. 14/23149-2); Grant Mechanism Regular Research Grant; Principal Investigator Ricardo Vieira (INPE); Investment R$156,558.58.