DRüMThe solution for Brazil increasing its sugar and ethanol production by up to 50%, without needing to plant one more additional square meter of sugar cane may lie at the bottom of the sea. The amount that the country is likely to produce this year is 37 million tons of sugar and 23.6 billion liters of ethanol. Studies carried out by the Federal University of Lavras (Ufla), in Minas Gerais State, in partnership with TWB Mineração, whose headquarters are in Guarujá, on the coast of São Paulo, have revealed that the use of biofertilizer made from calcareous marine algae, called bioclastic granulate, is capable of generating a significant gain in productivity in sugar plantations because it raises the plant’s sugar concentration, or sucrose.

DRüMThe solution for Brazil increasing its sugar and ethanol production by up to 50%, without needing to plant one more additional square meter of sugar cane may lie at the bottom of the sea. The amount that the country is likely to produce this year is 37 million tons of sugar and 23.6 billion liters of ethanol. Studies carried out by the Federal University of Lavras (Ufla), in Minas Gerais State, in partnership with TWB Mineração, whose headquarters are in Guarujá, on the coast of São Paulo, have revealed that the use of biofertilizer made from calcareous marine algae, called bioclastic granulate, is capable of generating a significant gain in productivity in sugar plantations because it raises the plant’s sugar concentration, or sucrose.

The researchers discovered that when applied to the crop as fertilizer mixed with dunder, the waste from sugar and alcohol production already used as a fertilizer by various mills in the country, bioclastic granulate replaces minerals in the soil and conditions it, adding more than 40 nutrients that are important for the development of the sugar cane, among them calcium, silica and magnesium. “This new source of nutrients for agriculture has an important role to play in correcting soil acidity. It rectifies the pH in acid soils, thus improving the assimilation of nutritional elements,” says agronomist Paulo César Melo, a professor at Ufla and one of the first researchers to analyze the use of granulate for fertilizing crops in Brazil. “At the same time, granulate eliminates the characteristic foul smell of dunder, because it absorbs the volatile gases it gives off.”

Bioclastic granulates are sand and gravel constituted mainly of marine algae from the Corallinaceae family. These algae, whose best known species is the genus Lithothamnium, precipitate magnesium and calcium carbonate onto their cell walls in a concentrated volume that is greater than in any other living organism. Of vegetable origin, they grow at depths that vary between 10 and 40 meters and in their natural state have a reddish or bluish color. The Brazilian continental shelf has one of the biggest deposits of calcareous algae in the world, in a 4,000 km strip that extends from the coast of Pará to Rio de Janeiro.

The existence of such abundance of these algae on the continental shelf in Brazil’s North and Northeast regions was reported in the 1960s by researchers from the Federal University of Pernambuco (UFPE). The latest discovery was an area covering 21,000 square kilometers, identified in the region of the Abrolhos archipelago on Bahia’s south coast (see Pesquisa Fapesp issue 196). “In Europe, mainly in France, these algae have already been used for decades for feeding animals and plants. Here in Brazil their use is recent and started only around 20 years ago. But the potential for economically exploring the algae on the Brazilian shelf is greater than that of the French deposits,” Melo points out.

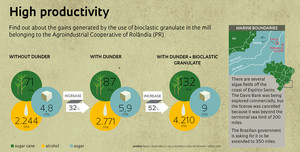

The use of bioclastic granulate as fertilizer was the subject of a PhD thesis defended by the researcher in the soil science department at Ufla. At the time, he evaluated the efficiency of the product on sweetcorn and bean crops. This was in 2002. Six years later, Melo was approached by TWB, which was exploring a deposit of calcareous algae 300 miles off the coast of Espírito Santo, and wanted to find economically profitable applications for the raw material. “At that time, my studies already showed that granulate increased sugar concentrations in fruit, like oranges, passion fruit, pitaya, paw-paw and guava. So we had the idea of testing it on sugar cane crops, one of the most important in the country,” the researcher recalls. To do so an agreement was signed with the Agroindustrial Cooperative of Rolândia (Corol), in Paraná, to use the granulate on the sugar plantations of the Fazenda Santa Rosa, in the municipality of Jaguapitã. Before putting it on the fields, studies were carried out in Ufla’s laboratories to define the recommended dose of the product, according to the analysis of the soil in the location, the history of the cultivated area and the amount of fertilizer applied on the plantation. In November 2009, the researchers mixed the granulate with 18,000 liters of dunder, a waste product from the sugar and alcohol industry, which were then spread on the sugar plantation. To evaluate the agricultural efficiency of the innovation, the researcher used a methodology called a local production arrangement (LPA), used by the Brazilian Agricultural Research Corporation (Embrapa), which consists of evaluating and validating a certain product on a specific crop and location, and then comparing the results with the result of a crop that did not receive that product. In the study undertaken by Melo, an area of 3,600 square meters of sugar plantation on the Fazenda Santa Rosa was divided into three. The granulate with dunder was spread on the first area; just dunder on the second; and neither of the two products on the third.

LÉO RAMOSCalcareous granulate already crushedLÉO RAMOS

Eleven months later the sugar cane was harvested and tests were carried out to evaluate the agricultural efficiency of the granulate. “The use of the granulate together with dunder, in comparison with just using dunder, led to a significant increase in sugar. We also saw that there was a 52% increase in the production of sugar and alcohol. Bioclastic granulate boosts the action of the dunder,” says Melo. Production of alcohol per hectare in the area fertilized with granulate and dunder reached 4,210 liters compared with 2,770 liters in the area treated just with dunder. Sugar production, in turn, reached 9,020 kg compared with 5,937 kg. The comparison between the area where the granulate and dunder mixture was spread with the area that received neither of the products revealed an even greater gain, in the order of almost 100%.

One advantage of the use of granulate as a biofertilizer, according to Melo, is its low processing cost. After the calcareous algae are removed from the bottom of the sea by dredging, no industrial beneficiation is necessary. The algae are processed by being dried naturally, and the product is bagged and stored. “Bioclastic granulate is an organic product that is not poisonous to man, and is cheaper and more efficient than conventional chemical fertilizers. The whole of its production cycle – extraction, processing and transportation – has no impact on the environment,” says the professor from Ufla. “During the dredging we extract just the free forms of the algae, in other words the exoskeleton, which is the dead part, such as rhodolites, nodules and their fragments. The area at the bottom of the sea where these algae banks are looks like a desert, with practically no marine life, except for large fish.”

Environmental impact

This type of algal exploration worries the scientific community that studies rhodolites. “The exploration of calcareous algae causes an environmental impact because, in practice, this is a non-renewable natural resource. Rhodolites grow very slowly and are a little bigger than a tennis ball. They may take 8,000 years to form,” says biologist Rodrigo Leão de Moura, a professor at the Biology Institute of the Federal University of Rio de Janeiro (UFRJ). According to Moura, rhodolites are responsible for the complexity of the sea bottom and add algal biomass, invertebrates, and a series of commercially important species, like lobsters and reef fish. “There’ll always be an impact, but it can be reduced if extraction takes place in small and carefully chosen areas, which we’ve not seen with this type of enterprise.”

PAULO MELO / UFLAGranulate spread on the sugar cane crop with dunderPAULO MELO / UFLA

At least three Brazilian companies, with ‘mines’ approved by the Ministry of Mines and Energy, already sell the product or have shown an interest in extracting calcareous algae from the Brazilian coast. Oceana Brasil is currently exploring a deposit 50 km off the coast of Tutoia, in Maranhão. The crushed and bagged product costs R$ 750.00 a ton at the plant and is called Algen. Another company, Algarea Mineração, is extracting the resource from a reserve off the coast of Espírito Santo. For three years TWB has been exploring a large deposit of calcareous algae on the so-called Davis Bank, located some 300 nautical miles off the coast of Espirito Santo in the Vitória-Ilha de Trindade underwater chain. In 2008, the company was granted two permits by the National Department of Mineral Production (DNPM), a body linked to the Ministry of Mines and Energy, to explore the deposit, but in 2011 its licenses were revoked, since it was alleged that the reserve was in international waters, beyond the Brazilian maritime border, the limit of which is 200 nautical miles (370 km) from the coast.

The potential extraction of this reserve of 150,000 hectares is enormous. According to Paulo César de Melo, at an extraction rate of 1 million tons a year, the deposit would only be exhausted in 2000 years. “Cancelling the research authorizations meant that TWB lost interest in the project.” The company invested approximately R$ 5.8 million without obtaining the prospect of a solution for continuing with the operation,” says the consultant and partner of TWB, João Manoel de Lima Monteiro. “The company halted the project and is concentrating on other areas of activity,” he says.

One of the alternatives for making exploration of the Davis Bank feasible would be to extend the Brazilian continental shelf beyond its current 200 nautical miles. The Brazilian government is requesting from the Commission on the Limits of the Continental Self (CLCS) of the United Nations Convention on the Law of the Sea an extension of its continental shelf, with the incorporation of an area of almost 1 million square kilometers to the 3.5 million square kilometers of maritime space that already belong to the country. Called the “Blue Amazon,” because of its great size and the natural resources it contains, this region has an extensive list of mineral resources in its sub-soil, like diamonds, zirconium, potassium, sand and gravel, in addition to its deposits of calcareous algae.

Scientific article

MOREIRA, R.A. et al. Crescimento de pitaia-vermelha com adubação orgânica e granulado bioclástico. Ciência Rural online. v. 41, no. 5. May 2011.