Car tires, made from rubber, steel, polyester, and nylon, are gaining another component: nanocellulose, which are nanometric fibers or crystals extracted mainly from plants and presented in the form of a white paste. A test version, with nanometric cellulose fibers from eucalyptus, pine, and sugarcane, is driving on the streets of Thomaston, a city in Georgia, USA, apparently, according to the manufacturer, with a 15% reduction in fuel consumption due to lower friction with the surface.

Because it is able to increase the mechanical resistance, reduce the weight, and improve the texture of many materials, nanocellulose has been valued as a potential additive for paper, rubber, plastic, paint, and cement. Already produced on a commercial or pilot scale in the USA, Canada, Brazil, Sweden, Norway, Israel, China, and Japan, it could also be used in prosthetics, coatings for electrical devices, and in cosmetics, medications, or foods. The multiple possibilities for the use of cellulose nanofibers, nanocrystals, and microfibers (with a diameter in the order of micrometers, extracted in a stage before the nanometric scale fibers) indicate a global market estimated at US$2 billion in 2030 by the US consulting firm MarketsandMarkets. The sector should be boosted by the growing demand for renewable materials, especially in Europe.

Nanocellulose is part of a race for more sustainable additives and compounds that can substitute petroleum derivatives. Besides the large cellulose producers, which are studying how to use them to strengthen paper and packages, the US consultancy firm estimates that companies from the automotive sector should be one of their main users, given the prospect of producing lighter parts, which could lead to a reduction in the weight of vehicles.

Responsible for testing the tires in Thomaston, GranBio, a Brazilian biotechnology company, manufactures two types of nanocellulose, obtained through different processes, in a pilot-factory in the US city, with the capacity to produce 1.5 tons (t) per year. The first is a nanofiber, which looks like a long spaghetti under an atomic force microscope, mostly used for strengthening plastics and paper. The second is composed of nanocrystals that resemble grains of rice, but 200,000 times smaller, with 5 to 20 nanometers (nm) in diameter, with more noble applications, such as protective films for works of art. The lengths of the two types vary from nanometers to tenths of micrometers.

GranBioDirector of Technology Kim Nelson evaluates cellulose nanocrystals produced at the GranBio pilot-factoryGranBio

“Our strategy is not to sell nanocellulose as a commodity, but to create consumer goods in which it is added,” explains civil engineer Bernardo Gradin, president of GranBio. One of the applications that has proved possible is a mixture with nanocellulose fibers that makes cardboard boxes lighter and water resistant for deliveries using drones.

The progress of the projects depends mainly on increasing the amount of material produced. In four years, Gradin expects to reach commercial scale production for tires developed with the Indian multinational Birla Carbon, a manufacturer of carbon black additives, a petroleum derivative mixed with rubber to give it resistance.

In principle, nanocellulose could substitute at least part of the carbon black. Studied for six years, the nanofibers used have a lignin coating, a molecule that helps in the strength and rigidity of plants, as described in an article by researchers from the two companies published in the journal Rubber Chemistry and Technology in October 2020.

In turn, Canadian company CelluForce, the largest global producer of nanocrystals extracted from wood, whose shareholders include Brazilian paper and cellulose manufacturer Suzano, has made a 10-year agreement with an unnamed multinational cosmetics company to build a new factory in a still undisclosed location and increase its production, which is currently 300 t per year. The crystals extracted from plants may improve the viscosity of skin creams, as in the case of tires, by substituting undesired compounds.

In São Carlos, in the countryside of the state of São Paulo, another partnership brought together the teams from startup BioNano and the Instrumentation unit of the Brazilian Agency for Industrial Research (EMBRAPA) to develop methods capable of increasing the production scale of cellulose nanocrystals from cotton. “We went from 100 grams to 100 kilograms [kg] per month,” says materials engineer Ana Carolina Correa Bibbo, director of the startup. In collaboration with materials engineer José Manoel Marconcini, of EMPRAPA, the pilot factory began being planned in 2018, when BioNano received funding from FAPESP’s Research for Innovation in Small Businesses program (PIPE).

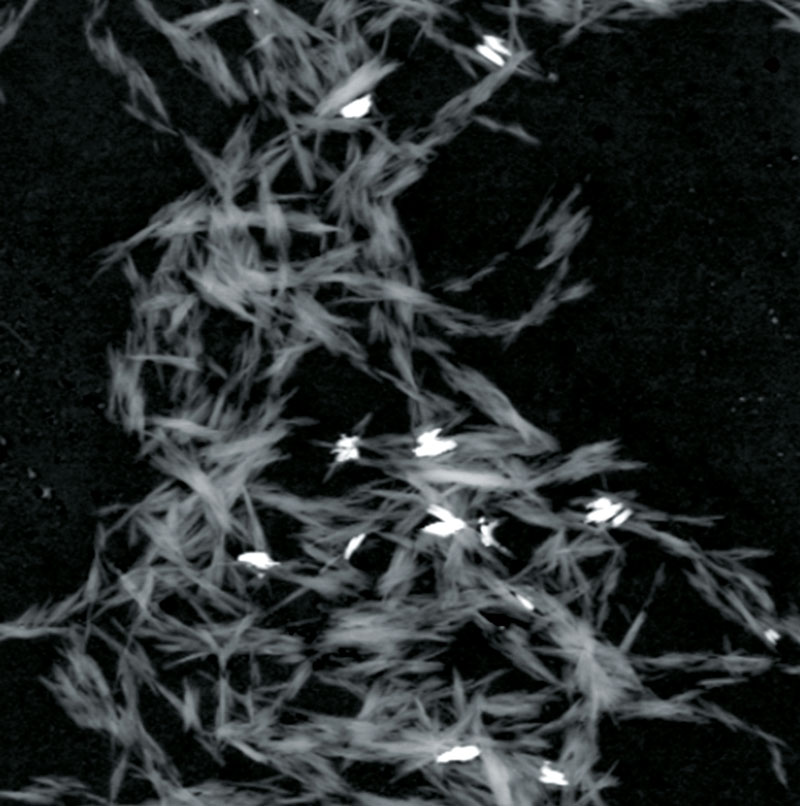

BionanoMicroscopy image of the transmission of nanocellulose crystals (white spots are denser regions)Bionano

One of the difficulties was finding a manufacturer of a midsized chemical reactor that was resistant to sulfuric acid, used to separate the crystals from the cotton fibers. This process results in a liquid mixture with a milk-like appearance, which is centrifuged and transforms into a dry white paste and then into a very fine powder.

Bibbo has been studying nanocellulose since 2010, when she did her PhD at the Federal University of São Carlos (UFSCar) and assessed the potential of using nanocrystals from curauá (Ananas erectifolius), a species of bromeliad from the Amazon region. With Marconcini and other researchers from EMBRAPA, she formulated a version of a plastic known as ethylene-vinyl acetate (EVA), with 5% of nanocrystals from the plant, which gained more strength and elasticity, as described in an article from 2020 in Polymer Composites.

At the company, she used the cotton fibers to simplify production. “Any other raw material would need to undergo purification pretreatment,” she explains. Since September 2022, she has supplied the material for research groups from São Paulo, Mato Grosso, Santa Catarina, Paraná, and Ceará that are studying new applications for nanocellulose.

Another group from EMBRAPA Instrumentation has extracted nanocrystals from the lignocellulose of sugarcane leaves by means of an organic solvent pretreatment and acid hydrolysis, described in an article published in the journal Industrial Crops and Products in December 2020. In the Brazilian Center for Research in Energy and Materials (CNPEM), in Campinas, São Paulo State, researchers mixed nanofibers from sugarcane and eucalyptus bagasse to latex and created a sponge capable of absorbing pollutants, such as from oil spills, up to 50 times greater than its mass. The process was described in October 2020 in ACS Applied Nano Materials.

In August 2023, a workshop about nanocellulose in São Carlos sought to strengthen the integration between the academic community and companies. “The expectation is that the steps for the transfer of technology, which will yield royalties to the research unit, will be completed in the first months of 2024,” explains Marconcini. As soon as this occurs, BioNano expects to start selling the nanocrystals on the Brazilian market.

Project

Obtaining cellulose nanocrystals (CNCs) on an industrial pilot scale (nº 17/00915-0); Grant Mechanism Research Grant ‒ Innovative Research in Small Businesses (PIPE); Principal Investigator Ana Carolina Correa Bibbo; Investment R$196,563.46.

Scientific articles

TUNNICLIFFE, L. B. et. al. Reinforcement of rubber by carbon black and lignin-coated nanocellulose fibrils. Rubber chemistry and technology. Vol. 93, no. 4. Oct. 2020.

BIBBO, A. C. et. al. Cellulose nanocrystals from curaua fibers and poly [ethylene-co-(vinyl acetate)] nanocomposites: Effect of drying process of CNCs on thermal and mechanical properties. Polymer Composites. Vol. 4. Jan. 2020.

BILLATO, S. et. al. Lignocellulose nanocrystals from sugarcane straw. Industrial Crops and Products. Vol. 157. Dec. 2020.

GOUVEIA, R. F. Porous cellulose nanofibril–natural rubber latex composite foams for oil and organic solvent absorption. ACS Applied Nano Materials. Vol. 3, no. 11. Oct. 2020.