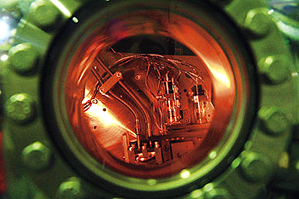

Source of light in one of the LNLS work stations

Two new very powerful light lines, to be used in experiments in the environmental area to evaluate the effectiveness of catalysts, which are indispensable when it comes to accelerating certain chemical reactions in industrial processes, and for research into the structures of proteins, are just some of the things that are new at the National Synchrotron Light Laboratory (LNLS), in Campinas, in the state of São Paulo, as it completes ten years of activities in July. The two pieces of equipment have been added to the 11 that were already there, which makes 13 work-stations in all. In addition to research institutions and universities, several companies use the laboratory’s sophisticated equipment, via agreements or made-to-order research. In late June, another important announcement for LNLS was made. Diamond Light Source, from the United Kingdom, formally signed a partnership with the laboratory to develop research projects using synchrotron light. This agreement will enable joint technical research and development programs to be carried out, in addition to allowing for the exchange of researchers between the two laboratories.

The objects that are studied using synchrotron light are extremely varied, ranging from organic structures, such as proteins, to inorganic systems with nanometric dimensions (a measure equal to 1 millionth of 1 millimeter), all of which are examined in detail with the help of a particle accelerator that can produce light across a broad electromagnetic spectrum, including invisible light, X-rays, ultraviolet light and infrared light. Synchrotron light is emitted by high-energy electrons that move in a circular accelerator or storage ring, from where it is distributed to the 13 work-stations where the researchers conduct their experiments.

Conceived in 1987 to operate as an open and multidisciplinary institution, the laboratory, linked to the Ministry of Science and Technology, was built by Brazilian researchers. In order to do this engineers and researchers paid several short technical visits to laboratories abroad and also hosted visits from foreign colleagues. Ten years of work were needed for planning and constructing the source of synchrotron light, the heart of the laboratory. By late 1996, the equipment was ready and in July 1997 the laboratory received its first users. “In 2006, more than one thousand researchers worked in the laboratory on 683 research projects,” says José Antonio Brum, physicist and Director-General of the LNLS. Five years before, in 2001, there were 267 projects. Almost 15% of the users are foreigners, mainly from Latin America, but also from South Africa and even from Europe and the USA. A team of 16 of the lab’s own researchers, who are responsible for the equipment and for providing support for external users, is engaged in research programs.

The growth in the number of users also reflects the way in which the synchrotron facilities have been extended. Between 1999 and 2006, for example, the laboratory went from eight to eleven light lines and this year it received a further two. One of them is the X-ray absorption line, aimed mainly at researchers in the area of materials science. “We already have a facility of this type but demand is three or four times greater than our capacity to help,” says Brum. The new line has a more intense flow of X-rays, which enables other types of experiment in the environmental area, with studies into magnetic materials and chemical catalysts.

The other line is for studies into the structure of proteins. The difference vs. the other source of light also used for this purpose, one of the first to be installed in the laboratory, is that besides offering a bigger photon flow, it`s instrumentation is more sophisticated. This is the first synchrotron line fed by an insertion device, called a wiggler, which is capable of emitting more light. With a greater flow it became possible to develop a diffraction technique for protein crystallography, enabling the study of molecules whose three-dimensional structure is completely original. “This is the first time that it has been possible to do this type of experiment in Latin America, which will lead to a qualitative leap in biology and biotechnology research,” says Brum.

In addition to these two lines there is a third one, which is in its final construction stage, and that concerns the visible and ultraviolet spectrum band, which will allow scientists to look at the duration of life of some processes involving proteins. “It’s a different type of line that can look at the dynamics of certain biological and chemical systems,” says the LNLS director. The chief innovation is that it was produced by an elliptically polarizing undulator (EPU), equipment made by LNLS researchers who, in May, won the Inventor of the Month award from Autodesk, a US engineering software company. The six-ton undulator is the first one ever made in Brazil.

Competitive source

By controlling the several types of light, researchers can “see” objects on an invisible scale. “Particularly in the band of hard X-rays, a light with a shorter wave-length, which penetrates deeper into the material, we’re a very competitive source relative to the conventional sources installed in smaller laboratories,” says Pedro Tavares, physicist, Associate Director of the LNLS and a member of the pioneering team that developed the Brazilian synchrotron. This is because the user can tune in precisely to what he wants by changing the wave-length. This is a very particular feature of synchrotrons. “What may take two weeks to analyze in other places we can do here in minutes or hours,” Tavares emphasizes.

As the flow of light produced in the synchrotron is very great, on can see both organic materials (such as proteins) and inorganic materials (semiconductors, metal alloys, etc.) at the atomic level. “By understanding how their properties function we can synthesize the material for a particular property to be explored,” says Brum. The objective of an agreement signed with Petrobras at the end of last year, for example, is to evaluate materials, with an emphasis on catalysts, which are indispensable for oil refining. This means not only characterizing the ready material, but above all understanding what happens during the synthesis process. “We’re beginning to develop specific lightline experiments to carry out the characterization “in situ”. This means that while the material is undergoing its transformation it is also being analyzed by X-ray, which allows the modifications that have occurred to be correlated to its efficiency as a catalyst,” points out the laboratory’s director.

The LNLS also has an agreement with Oxiteno to characterize the catalysts developed by the company. The first contract was signed in 2005 and renewed in 2006. “We have analyzed several families of catalysts at various stages,” says Daniela Zanchet, a researcher at the LNLS. Some of them are still at the laboratory stage, whereas others are very close to the final stage. One of them has already been launched on a pilot scale and has gone into industry. Oxiteno manufactures catalysts for their own use as well as for other companies. “With these groups where we are working in partnership, the company synthesizes the material and the catalysis while we characterize them,” says Daniela. Synchrotron technology allows for a precise understanding of what happens with particles during the reaction. The generation of knowledge resulting from this partnership is important for the company when it comes to identifying problems quickly and solving those that may arise in the future with the product. While still on an initial laboratory scale the trials last a few hours and are done with ultra-clean reagents; in industry the catalyst functions under completely different conditions and for several years.

When samples are very small or diluted, the light flow from the synchrotron is essential for obtaining accurate results. “We analyzed the water and sediment from the Billings Reservoir and found it contained very high concentrations of chromium, nickel and lead, above the limits established by the Environmental Sanitation Technology Company (Cetesb),” says the research coordinator, Professor Silvana Moreira, from the School of Civil Engineering at the State University of Campinas (Unicamp). The work was done on the X-ray fluorescence line, which enables the quantification of metals even when they are present in minute quantities.

Another study by the same group evaluated metal concentration in trees’ growth rings, which reflect environmental pollution over the years. “As the samples are very small, weighing 20 to 30 milligrams, it is highly unlikely that the conventional method would manage to detect heavy metals,” says Silvana. The study compared trees from a region with very little traffic to trees from another area in the Campinas region, where traffic is very heavy. “In this case, besides the pollutants, we found that the lead concentration fell starting in 1990, when the law that prohibited using lead as an additive to gasoline came into force,” explains the researcher.

In addition to the light source, LNLS also has research infrastructure in its Structural Molecular Biology Center (Cebime), which is part of the Molecular and Structural Biotechnology Center (CBME), one of FAPESP’s Research, Innovation and Dissemination Centers (Cepid). Cebime research focuses on three themes. One of them deals with the proteins of Trypanosoma cruzi, the agent that causes Chagas disease, which affects nearly 5 million Brazilians.

The objective of the project, carried out in collaboration with the Paraná Institute of Molecular Biology, linked to the Oswaldo Cruz Foundation (Fiocruz) and a further five universities, in addition to the Pasteur Institute in France, is to analyze the function and structure of the proteins that are produced in a different way by protozoa at each phase in the parasite’s life cycle. Through this, the researchers hope to identify the proteins that control the changes in each phase. “Subsequently, exploiting the fact that some proteins bind small molecules together, we may be able to modify them so as to repress a protein’s function, which may lead to inhibiting the parasite’s propagation,” says Nilson Zanchin, a researcher from Cebime.

The objective of the second theme is firstly to identify the genes that play an important role in the generation and maintenance of leukemia and, secondly, to characterize the function of the proteins codified by these genes, in order to generate ways of neutralizing them. The work is being conducted jointly with the Boldrini Children’s Center in Campinas. The third theme concerns the interaction between plant bacteria and parasites, such as Xanthomonas axonopodis citri, that causes citric chancre, and Xylella fastidiosa, that causes disease in oranges. By understanding how the bacteria infect citrus plants, researchers may find a way to block the infection caused by the invader.

The lightlines are in the synchrotron, where data about the diffraction of X-rays are collected for resolution of the structure. To do so one must first obtain a crystal from this protein. In general, the complete process involves cloning the protein. After it is purified crystallization trials are carried out; they are necessary to organize the protein molecules into three dimensions in the crystal. The crystals, which are about 100 micrometers or one tenth of a millimeter long, are studied with a high intensity beam of X-rays. However, the process to reach the crystals is not easy. “The study of a protein may be the equivalent of a doctoral thesis,” says Zanchin. Some proteins take two years to crystallize, others five and researchers are unable to complete the process for some. When this happens one can use an alternative method for studying its structure, based on nuclear magnetic resonance equipment, with a magnetic field hundreds of times that of the Earth.

Industrial processes

Research with the synchrotron covers a great range of themes. In the nanotechnology area, for example, electronic microscopy complements the studies conducted with lightlines. In the microscopy laboratory, physics and chemistry studies with carbon nanotubes, metallic nanoparticles for catalysts, semiconductors and fuel-cells are carried out, in addition to research on the growth of quantic points, in collaboration with other laboratories. One of the studies conducted between 2004 and 2006, for example, was commissioned and paid for by a conglomerate of US and European companies that are major manufacturers of products used in industrial welding processes, via a law firm based in the United States. “We did a study into the vapors resulting from the industrial processes that involve welding materials. They carry some metallic elements that may be harmful to workers’ health, such as manganese that causes a disease called manganism,” says Antonio José Ramirez, a researcher from the Electronic Microscopy Laboratory.

The study consisted of characterizing the vapors that condense and form solid nanoparticles when they are expelled in the industrial process. In the case under study they comprised a nucleus of magnetite (iron oxide) contaminated with manganese. “We discovered that they had an external layer of silicon dioxide that functions like a protection capsule, minimizing the effect of the manganese, which may explain the lack of a link with the appearance of the disease,” says Ramirez. Other physical, chemical and biological studies are still necessary to understand this phenomenon better.

Electrons travel around curves and along straight lines

The synchrotron light is generated in a huge storage ring, the circumference of which is 90 meters, made of curves and straight lines. Produced by a particle accelerator, electron beams move in a vacuum tube at speeds approaching that of light. Electrons are deflected by bipolar magnets, emitting the synchrotron light. This synchrotron light generator emits white light, with all the bands of the spectrum. In addition to visible light it groups other electromagnetic waves that cannot be seen by the human eye, such as X-rays and infrared and ultraviolet radiation, in a condensed way. The light that comes out at several points around the ring is distributed to the work-stations. The 13 lightlines are coupled to the circular electron accelerator and receive synchrotron light from the machine. In addition to the 12 bipolar magnets distributed around the storage ring, which make the light circular, two insertion devices – a series of magnets that produce deviations on the straight stretches of the large tube – were installed to stimulate the emission of light.

Republish