An estimated 350 million LED bulbs are sold annually in Brazil. These bulbs are far more energy-efficient than their incandescent and fluorescent predecessors and can last anywhere from 25,000 to 50,000 hours, manufacturers say. But once they reach the end of their lifespan, many are not sustainably disposed of. To lower their environmental footprint and return valuable materials into the economy—LED lamps contain precious metals like gold, silver, and copper, as well as rare earth elements such as yttrium and cerium—Brazilian researchers are exploring ways to profitably recycle discarded LED lamps.

One of the most advanced research projects is a collaboration between São Paulo’s government-run Institute for Technological Research (IPT) and Tramppo Reciclagem, a company based in Osasco. The team has devised a method to physically dismantle and separate the various materials inside an LED lamp. The innovative process has led to two patent filings with Brazil’s National Institute of Industrial Property (INPI).

“We partnered with IPT back in 2018 to develop recycling technology for LEDs. Seven years on, we now have a working prototype that automates the entire dismantling process,” says Carlos Alberto Pachelli, cofounder and director at Tramppo. “By the end of the line, the system separates out polymers, metals, and ceramics for recycling,” he explains. “As far as we know, we’re the first to mechanize the process. Most recycling companies still do it by hand, which isn’t scalable to meet demand as LED waste keeps piling up.” The project has received funding from multiple Brazilian institutions, including the Innovative Research in Small Businesses (PIPE) program, the Brazilian Agency for Industrial Research and Innovation (EMBRAPII), and the Brazilian Micro and Small Business Support Service (SEBRAE).

LED bulbs come in various shapes, the most common being tubular, pear-shaped (bulb), and globe styles. Their primary components include a plastic or glass housing, an LED strip, and an electronic driver mounted on a printed circuit board. While glass makes up most of the mass, it’s not where the value lies. The real value is in the LED strip and circuit board, which hold the precious metals, as reported in a 2024 study from the IPT team analyzing the chemical makeup of bulb-style LEDs, published in Tecnologia em Metalurgia, Materiais e Mineração.

Experts agree that recycling LED lamps is critical from both an economic and a sustainability perspective. “Recovering rare metals from these lamps means we can reuse them in other products instead of mining more from the ground—which lowers environmental impacts,” says chemical engineer Sandra Lúcia de Moraes, who manages the IPT’s Advanced Materials Unit and is heading the project. At the same time, she adds, it helps cut down on electronic waste. LED lamps contain plastics and potentially toxic metals like copper, zinc, and lead, which can build up in the environment—polluting soil and water, damaging ecosystems, and posing risks to human health.

Léo Ramos Chaves / Pesquisa FAPESP | Tramppo Circuit terminals (left), LED strips (center), and crushed glass from discarded lamps (right)Léo Ramos Chaves / Pesquisa FAPESP | Tramppo

The missing step: physical separation

Until now, LED recycling worldwide has focused almost exclusively on extracting precious metals from the light-emitting diodes themselves, says Moraes. But few efforts have tackled the earlier step—physically separating materials before any metallurgical extraction. “The recycling systems common in Europe aren’t suited to Brazil,” she explains. “They skip the material separation phase that would allow us to recover plastic, glass, aluminum, and copper—materials that hold value in Brazil’s recycling market.”

Conventional methods jump straight into chemical extraction, using solvents to recover the metals. The conventional process begins with comminution (particle size reduction), in which the whole lamp is crushed into a fine powder. “That powder then goes through chemical extraction, which consumes a lot of reagents and leaves behind a substantial volume of waste,” says Moraes. “Plastic and glass get tossed out in the process.”

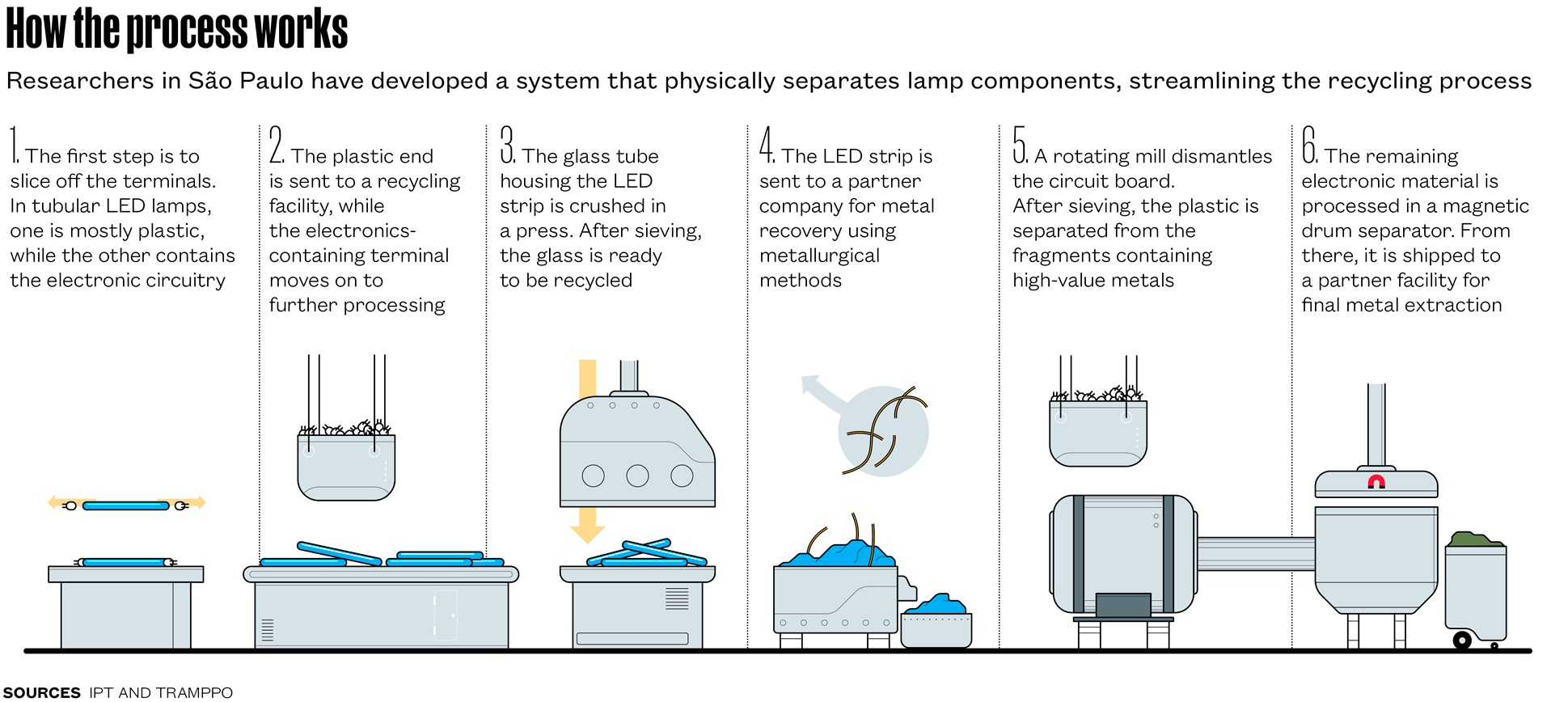

What sets the method developed at IPT and Tramppo apart is what happens before any metal is extracted: they dismantle the lamp and physically sort out recyclable materials. To make it work, the team built a custom machine designed to disassemble LED bulbs and sort their parts. In the case of tubular LEDs, the first step is slicing off the terminals, which contain the electronic circuitry. A key innovation in the process is the use of an autogenous mill—a rotating, cylindrical device that breaks down the lamp’s electronic components, making it easier to recover the metals inside (see infographic below).

“The toughest part was designing a system that could disassemble the lamp—including the LED strip—and separate everything into relatively coarse materials,” explains IPT mining engineer Francisco Junior Batista Pedrosa. This step, carried out before any metallurgical processing, cuts down the total volume of material entering chemical extraction—helping to reduce environmental liabilities. “In mining, this approach is called preconcentration,” Pedrosa explains. “The concept is to filter out the low-value material early, so only what’s worth processing moves forward.” Pedrosa is also a coauthor of a 2023 study on how LED lamps break down mechanically, published in the Proceedings of the 76th Annual Meeting of the Brazilian Association of Metallurgy, Materials and Mining (ABM).

Tramppo’s production line, which was initially designed 10 years ago to recycle fluorescent lamps with funding from FAPESP (see Pesquisa FAPESP issue n° 146), began trial operations earlier this year. The current system can handle about 500 kilograms (kg) of waste per day. According to Pachelli, upgrades to the system could scale that capacity fourfold. The separated glass, which makes up the bulk of the material, is sent to the ceramics industry. Plastics go to local recycling firms. The precious metals in the circuit boards are extracted by a specialized overseas company. Tramppo and IPT are now looking to develop a recovery process specifically for the metals embedded in LED strips and electronic terminals.

Lúcia Helena Xavier, a researcher at Brazil’s Center for Mineral Technology (CETEM), under the Ministry of Science, Technology and Innovation (MCTI), describes the IPT-Tramppo recycling process as a significant innovation. “Their machinery has the capabilities to separate LED lamp materials efficiently and automatically, making the process economically viable,” says Xavier, who was not involved in the project. “Without that step, the downstream recycling steps become less efficient.”

A specialist in reverse logistics, urban mining, and circular economy strategies, Xavier coauthored a 2020 report on LED recycling, presented at the 11th International Solid Waste Forum in Porto Alegre. The study outlined the state of LED recycling technologies in Brazil. Back then, one of the biggest challenges was the complete absence of a standardized recycling system for LEDs.

Today, CETEM is investigating how to extract critical and high-value metals from LED waste. “We’re working on the chemical and physical characterization of LED residues and processing methods to selectively separate out elements like copper, silver, and gold,” explains chemist Larissa Oliveira Alexandre, a researcher at CETEM. “It’s a straightforward two-step process that doesn’t generate any liquid waste—but I can’t go into detail yet because we’re still filing for a patent,” she says. “What I can say is that the output contains much higher concentrations of yttrium, gallium, copper, and silver than naturally mined ores—so it could significantly reduce the need for primary extraction.”

A southern route

At the Federal University of Santa Maria (UFSM) in southern Brazil, chemical engineering researchers are pursuing a recycling route similar to the one developed by Tramppo and IPT, also centered on mechanically processing discarded LED lamps. “We’re applying a combination of grinding, magnetic separation, and electrostatic separation to dismantle the major components of the waste,” explains chemical engineer Daniel Bertuol, who is leading the research project at UFSM.

Much like the São Paulo approach, the mechanical stage allows certain materials to go straight to recycling, while others—particularly the LED chips and circuit boards—still require metallurgical processing. A key difference is that the UFSM team skips both the terminal-cutting step and the use of an autogenous mill to break down the electronics. The team published their findings in Resources, Conservation and Recycling back in 2020.

“When we ran this study, very little research had been done on LED recycling,” says Bertuol. “Our paper helped establish baseline data on the chemical makeup of the components and outlined a viable mechanical separation method.” The UFSM team has yet to build a working prototype for dismantling the lamps. “We developed pilot-scale equipment to develop and test the recycling route,” the team notes.

The story above was published with the title “Giving LEDs a second life” in issue 352 of April/2025.

Project

Development of LED lamp recycling technology (n° 19/16692-5); Grant Mechanism Innovative Research in Small Businesses (PIPE); Principal Investigator Elaine Menegon Chermont (Tramppo); Agreement FINEP – PIPE/PAPPE Subvenção partnership; Investment R$144,000.00.

Scientific articles

MORAES, S. L et al. Aproveitamento de materiais de lâmpadas LED: Investigando os mecanismos de desmantelamento de lâmpadas do tipo bulbo. ABM 76th Annual Conference. No. 76, pp. 239–50. 2023.

MORAES, S. L. et al. Chemical analysis of LED bulb components: Strategies for efficient recycling. Tecnologia em Metalurgia, Materiais e Mineração. Vol. 21. 2024.

REBELLO, R. Z. et al. Reciclagem de lâmpadas de LED inservíveis: Panorama atual e perspectivas futuras. 11th International Forum on Solid Waste. June 2020.

MARTINS, T. R. et al. Innovative method for the recycling of end-of-life LED bulbs by mechanical processing. Resources, Conservation and Recycling. Vol. 161. Oct. 2020.

Book

XAVIER, L. H. & OTTONI, M. (eds.). Mineração urbana – Conceitos e análise do potencial dos resíduos eletroeletrônicos. Centro de Tecnologia Mineral/MCTI, 2021.

Republish