Léo RamosNew levitator allows suspension and manipulation of lightweight substancesLéo Ramos

Levitating objects using just sound may seem like a magic trick, but it is not. Researchers at the University of São Paulo (USP) have developed a device that does just that. The novelty of this levitator in relation to others already developed is that it allows greater control of particles. The technology could facilitate the handling of hazardous materials or sensitive chemicals, such as compounds used in the manufacture of pharmaceuticals.

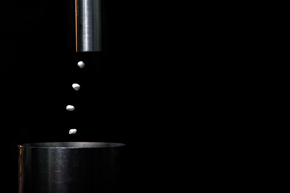

The apparatus—developed in the laboratory of engineer Julio Adamowski at the USP Polytechnic School—is capable of making small drops of polystyrene float in the air and consists, basically, of two parts. One of them, in the shape of a cylinder, emits high-frequency sound waves that are inaudible to humans. It is the transducer. The other, the reflector, is concave and is positioned below the first in order to reflect the waves and thus produce the levitation effect.

Equipment of this type is not new. One of the first acoustic levitators was described in the scientific literature in 1933 by German researchers. Resonance, the principle which allows most current levitators to suspend particles, is similar to that used in the first devices.

After emission, the waves ricochet several times between the transducer and the reflector. They interact with each other along the way and generate resonance, creating a wave with minimum (nodes) and maximum acoustic pressure points. This wave is known as a stationary wave because the nodes are at fixed points, as if it had a figure-8 format with the node at the center. When a particle is placed inside this stationary wave, the pressure produced by the sound balances the force of gravity and suspends the particle in the air, sitting on the wave pressure node.

The problem is that, in order to generate resonance, the transducer and the reflector need to be separated by a very specific distance—a multiple of half a wavelength. This makes it difficult to transport particles, since any movement of one of the two parts of the equipment destroys the resonance and, as a result, the levitation. The researchers’ idea, then, was to develop a non-resonant levitator.

“We built a transducer with a small diameter,” explains Marco Andrade, a physicist at USP and the principal investigator of the project, conducted together with Adamowski and the electrical engineer Nicolás Pérez, of the University of the Republic, Uruguay, who spent time at USP thanks to funding from FAPESP. “Thus, only a small fraction of the waves is reflected by the transducer.” The novel aspect of the device is that just a few reflections between transducer and reflector are enough to form a stationary wave.

Léo RamosResonant device supports heavier particlesLéo Ramos

Since resonance is no longer necessary, there is no need to precisely set the distance between the two halves of the equipment. Actually, as the two parts are moved further apart or closer together, the number of nodes in the stationary wave changes, which could allow levitation of several particles at the same time. Furthermore, the reflector can simply be moved in relation to the transducer in order to manipulate these particles.

The mechanism is more elegant and effective compared to the resonant method, but it has a drawback. The pressure generated by the sound waves is smaller than that generated when there is resonance, which limits the weight of the particles that it can levitate.

“Previously, we had built a resonant levitator able to levitate steel balls, which are about 150 times denser than polystyrene,” he says. “Therefore, our next step is to improve the new device. We intend to develop a non-resonant levitator capable of levitating heavier particles, such as droplets of liquid and metals.”

Applications

Resonant acoustic levitators are already on the market, but their use is still restricted mostly to academia. Levitation by sound waves is used in research in the biological sciences, materials science and analytical chemistry. For example, a liquid sample can be levitated and analyzed using spectroscopy techniques.

Andrade believes that, in the future, there will be many potential applications of acoustic levitators for handling hazardous—corrosive or superheated—materials and also in the pharmaceutical industry. Researchers at Argonne National Laboratory, of the United States Department of Energy, for example, seek to use the technique to improve the efficiency of certain drugs. The levitation of droplets containing the active ingredient of drugs prevents crystallization. This allows the drug to be better absorbed by the body when ingested later.

Another possible application could interest children. According to Andrade, acoustic levitation could be used to develop a new generation of high-tech toys. “Since an acoustic levitator is a relatively simple device to build, we believe that toys will be based on this technique in the near future.”

Scientific article

ANDRADE, M. A. B. et al. Particle manipulation by a non-resonant acoustic levitator. Applied Physics Letters. V. 106, No. 1, 014101. Jan. 5, 2015.