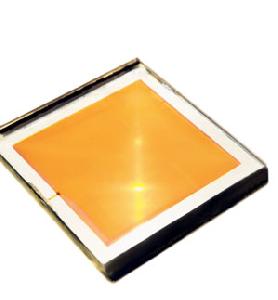

EDUARDO CESARSolar cell with inorganic ruthenium-based dyeEDUARDO CESAR

Solar cells that mimic the functioning of the photosynthesis process in plants has been studied and developed by Brazilian and foreign researchers, with results that promise a new generation of raw materials that are cheap when compared with the silicon used in converting sunlight into electricity. The new dye-sensitized solar cells (DSC) have proved to be a promising alternative for producing electricity worldwide. In Brazil, the research carried out in the Nanotechnology and Solar Energy Laboratory at the Institute of Chemistry at the State University of Campinas (Unicamp) resulted in a spin-off company, Tezca Células Solares, incubated in the Development Company from the Campinas High Tec. Center (Ciatec), which by 2012 intends to manufacture battery chargers for cell phones and cameras or those that can be attached to notebooks and toys.

“The company already has a patent for assembling solar cells from totally Brazilian material”, says professor Ana Flávia Nogueira, coordinator of a group of 15 researchers, comprising post-PhDs and science undergraduates, Masters and PhD students, who are developing devices to take advantage of solar energy. The researcher started becoming interested in the area in 1996, during her Masters dissertation, the tutor for which was professor Marco-Aurélio De Paoli, also from the Institute of Chemistry. Currently, the research he is coordinating concentrates on two technologies that use different mechanisms to convert solar energy into electricity.

One of them is based on dye-cell technology or photo-electro-chemical cells prepared with titanium dioxide (TiO2), a substance used in toothpaste and white paint for walls, that has semi-conductor properties. But as titanium dioxide does not absorb light because it’s white, it’s necessary to resort to a dye to sensitize it in order to promote the absorption of solar energy. “The term ‘sensitize’ can be used as a synonym for coloring titanium oxide with natural or synthetic dyes that absorb light in the band that is visible to the human eye”, explains the researcher.

Natural extracts

Inorganic dyes that possess a metal similar to the magnesium found in chlorophyll – vegetable pigments that function as photoreceptors in photosynthesis – are the most efficient for this task. So far the compounds of ruthenium, a chemical element used in catalyzers, have proved to be unbeatable in this role because of its capacity for absorbing and transferring energy. But other dyes have also given good results. In the University of São Paulo, the research group of professor Neyde Yukie Murakami Iha, from the Laboratory of Photochemistry and Energy Conversion, who since 1985 has dedicated herself to studying systems for storing and converting solar power, has tested natural dyes extracted from mulberry, jabuticaba, açaí, jambolan plum and other fruits and flowers that contain antioxidant pigments called antocianins that characteristically are red, blue and purple. “We made a solar cell with a natural dye that’s been working for more than a year”, reports Neyde. “The advantage is that it’s much more viable economically and harms the environment much less.”

EDUARDO CESARIn the laboratory at Unicamp, a cell is optically measuredEDUARDO CESAR

In 1995 the researcher started developing dye-sensitized solar cells. “The great encouragement for this research came from professor Michael Grätzel, of the Federal Polytechnic School of Lausanne, in Switzerland, who showed that the system using nanoparticles of crystals of titanium dioxide was commercially viable”, says Neyde. In 1991, Grätzel created a cell that, instead of using a single layer of titanium dioxide, was made from small particles of the metallic oxide that were almost 20 nanometers in diameter, covered by a fine layer of dye. The method increased the effective surface available for absorbing sunlight. Since then the Swiss researcher’s group and other research groups have tried to increase the power conversion efficiency of these devices, using new materials and innovative solutions for assembling the cells.

They basically work in a similar way to a cell phone battery, with two electrodes and between them an electrolyte, a conductor that carries the electrical charge by means of ions. “The functioning of these cells, which are assembled like a sandwich, constitutes a truly integrated chemical system”, says Ana Flávia. This system comprises a high light-absorbing dye that separates and transfers the electrical charge to the titanium dioxide and is regenerated by the electrolyte. The electrical charges separated in this process recombine after passing through an external circuit, creating an electrical current. At USP, a prototype of the 10 x 10 cm. solar cell shows the possibilities of this technology. When connected to a light source it’s capable of driving a small motor that turns a propeller.

Recently, G24 Innovations, from the United Kingdom, which holds the Gratzel patent license for Europe, started selling cell phone chargers and covers that have plates made from dye-sensitized flexible film for collecting solar energy. Australian company Dyesol is preparing to launch panels using this technology on a commercial basis for application in house and building façades. “It already has the technology for this”, says Neyde, who in 2007 visited the company. “The only reason it hasn’t launched the products in the market is because it wants a guarantee that maintenance will be carried out in an appropriate way so that the panels have a working life of ten years as planned.” To do so Dyesol is forming consortia with companies and research centers in several countries. “One of the great advantages of dye-cells is their capacity for operating under poor lighting conditions”, says Neyde.

The group from USP, which received funding from FAPESP and CT-Energ, the Energy Sector Fund of the Ministry of Science and Technology, to carry out the research, has deposited five patents with this technology. Some companies have shown an interest in beginning to produce the dye-cells, but negotiations are still on-going. “In addition to converting solar energy into electricity, this technology has the potential for producing hydrogen and methane, which can be used as fuel”, reports Neyde. USP’s laboratory has formed a partnership with professor Thomas Meyer, from the State University of North Carolina, for developing catalyzers and integrated systems to carry out artificial photosynthesis for producing solar fuels.

The other technology that is being researched at Unicamp, which is the same as that used in the flexible films of the products launched by the British company, is solar cells that use organic semi-conductor materials, such as polymers or molecules, as an active layer on the solar power equipment. To prepare these cells two semi-conductors are used that have different characteristics for electronic transport. In this case the two electrodes are placed directly in contact, without the need for an electrolyte. “Organic cells allow us to work with various materials. This leads to the development of flexible, colored and transparent modules”, says Ana Flávia. Since 1998 professor Ivo Hümmelgen from the Department of Physics at the Federal University of Paraná, has been researching these devices made from polymers, which can also be associated with fullerenes or nanotubes, nanometric structures made from carbon atoms. “As an active layer we use poliotyophenol derivatives, a family of polymers that has a very high absorption rate in the visible region of the solar spectrum”, says Hümmelgen. Fullerenes and nanotubes increase the efficiency of the process, because they are responsible for separating and transporting the charge in the device.

Power conversion

“A basic problem, both with dye-cells as well as with organic cells is that their efficiency is even lower than that of the inorganic silicon solar cells that are currently used”, says Hümmelgen. This is because the production conditions in the laboratory where processes are highly controlled cannot always be repeated in production on a large scale. While commercial cells based on polycrystalline silicon have an average efficiency of 11%, dye-cells get to 7% or 8% in the laboratory. “In some laboratories cells with a certified efficiency of up to 11% have already been obtained”, says Neyde. The calculations for measuring energy efficiency include all the sunlight that is converted into electricity. “This calculation takes into account the whole solar spectrum, which goes from the visible to the near infrared”, explains Neyde. “There are regions with 80% efficiency and others where nothing is taken advantage of.”

EDUARDO CESARPrototype connected to a light source drives a propellerEDUARDO CESAR

The cell phone chargers of the English company, G24, for example, allow a 20 minute conversation for every hour of sunlight. Despite seeming little, it has to be considered that this application is portable and ideal for locations that are not connected to the electricity grid. Despite being less efficient the technology is promising not only because of applications in isolated communities but also in urban areas. The forecast cost on an industrial scale is almost 50% less than that of a silicon cell. “As the presence of small impurities in the semiconductor does not create a problem for the working of dye-cells, complicated procedures necessary for manufacturing silicon cells, like the use of clean rooms and special clothes can be dispensed with”, says Neyde. The projected cost for organic and dye-sensitized solar cells is US$ 0.40 per watt, compared with the US$ 3 per watt for silicon-based technology.

In Brazil, the photovoltaic power generation potential is 10,000 megawatts (MW), almost the equivalent of an Itaipu power station, but it’s not possible to take advantage of it fully because it’s necessary to have places available for installing solar power stations. So far only 12 MW are effectively installed in isolated communities, while a further 80 are in systems connected to the electricity grid, but experimentally. Brazil is a major exporter of quartz, the raw material used for making solar grade silicon, but it does not dominate the technology needed for producing this high added-value semiconductor material. “The process for growing silicon crystals is extremely costly, because it involves enormously high temperatures and a complex lithographic process in order to obtain perfect crystals”, explains Ana Flávia. Another criticism made by the researchers’ regarding the use of silicon is the cost of the energy spent producing it. “For space purposes, for example, the technology justifies the final price”, says Neyde. But its high cost prevents it being used on a large scale. “The installation cost of a silicon-based solar collection system for a 200 sq. meter house is around US$ 35,000”, says Ana Flávia. The calculations were made by SunLab, a company from Bragança Paulista, in the State of São Paulo.

The project

Regenerative photo-electro-chemical solar cells using glass conductors containing protected filaments and modular association for assembling panels (nº 00/08434-0); Modality Support Program for Intellectual Property (Papi); Coordinator Neyde Yukie Murakami Iha – USP; Investment R$ 28,069.35 (FAPESP)

Scientific articles

NOGUEIRA, A.F., et al. Polymer solar cells using single-wall carbon nanotubes modified with thiophene pedant groups. Journal of Physical Chemistry C. v. 111, n. 49, p. 18.431-18.438, 20 Nov. 2007.

PATROCÍNIO, A.O.T., et al. XPS characterization of sensitized n-TiO2 thin films for dye-sensitized solar cell applications. Applied Surface Science. v. 254, p. 1.874-1.879, 15 Jan. 2008.