In September, the Lajinha, east Minas Gerais factory of the Brazilian subsidiary of NetZero, a Paris-based company, is set to begin continuous production of biochar using coffee straw (the outer skin of the bean) collected from 400 coffee plantations in the region. Those supplying this raw material will be the first to use the resulting black powder as compost on their land, and hope to obtain results at least similar to those of small-scale experiments conducted by research centers in Brazil and other countries.

Biochar is produced by oxygen-starved heating in ovens, known as pyrolyzers, of agricultural residues including corn cobs, babassu, rice, and cotton shells, sawdust and timber offcuts, açaí and dendê palms. The same plant may generate materials with their own chemical composition and properties. A March article in the Brazilian Journal of Animal and Environmental Research demonstrated that biochar made with Phyllostachys aurea, an exotic bamboo species, has higher carbon content than the Guadua sp., a native bamboo species; both are common in the south of the country.

In controlled studies conducted over the last 10 years, these formulations increased agricultural output by up to 50%, root growth by 30%, and growth of buds by 45%. They also favored absorption of nutrients, reducing chemical fertilizer use by some 20%, and helped the soil to retain water and contaminants. Significant value has also been conferred upon biochar for its ability to sequester — or literally bury — carbon, the most abundant chemical element in its composition.

Inaugurated in April, the Lajinha facility is the first on a commercial scale in Brazil. Built using its own technology on land donated by the Lajinha Region Coffee-Growers Cooperative (Coocafé), it has the capacity to produce 4,500 tons of biochar per year, still little against the 42 million tons of fertilizers consumed by Brazil annually. Some of the biocarbon will remain free of charge for suppliers of the raw material, who will be able to acquire the rest at a discount.

“The sale of carbon credits has enabled our business model, because it can subsidize the biochar sale price, which cannot be high,” French entrepreneur and NetZero cofounder Olivier Reinaud told Pesquisa FAPESP. According to Reinaud, French-British bank Rothschild and US consultancy Boston Consulting Group have already purchased credits generated by biochar produced in a factory inaugurated in January 2022 in Cameroon, Africa, also using coffee residues. “The credits correspond to around half of our revenue,” he said in a press release.

Aline Peregrina Puga The product applied to a corn cropAline Peregrina Puga

Aperam BioEnergia, a charcoal producer in Minas Gerais, announced in May that it had sold 921 carbon removal contracts, each corresponding to the removal of 1 ton (t) of carbon dioxide (CO2) from the atmosphere. According to a release by Aperam, the target is to produce 40,000 t of biochar per year, which would represent revenue in the area of R$40 million.

European companies produced some 21,000 t of biochar in 2020, while United States output was 45,000 t in 2017 and 2018, and may have reached 70,000 t in the subsequent years. The global biochar market may total US$205 million this year, and US$587 million in 2030, with annual growth of 13% according to an estimate by NGO Earth.

If used intensively around the globe, biochar may remove between 1.3 billion and 3 billion t of CO2 by 2050, according to Project Drawdown, a movement that seeks solutions to tackle the climate and environmental crisis. Despite the positive outlook, chemical engineer Henrique Poltronieri Pacheco, of the Alberto Luiz Coimbra Institute for Graduate Studies and Research in Engineering at the Federal University of Rio de Janeiro (COPPE-UFRJ), advises caution around carbon sequestration estimates.

“Without a full carbon footprint analysis from the cradle to the grave, as we say, it is not possible to state that biochar is effectively sequestering carbon,” he emphasizes. In addition, reduction of emissions with biochar may vary greatly due to the raw material used in its production, the dose applied, and the soil type.

Biochar in grains

In 2018, in the first of two projects supported by the FAPESP Innovative Research in Small Businesses (PIPE) program, administrator Braulio Pereira Neto, who heads up Carbosolo, was dealing with traditional biochar, made up of differently sized particles. There was an issue: the finer particles were easily blown away when applied to the soil. Tired of seeing this dust spreading, he developed an extruded — or granulated — fertilizer, with biochar. The new configuration facilitates application and prevents particles from entering the lungs of those handling it.

Gil Silva / NetzeroNetZero biochar fabrication facility in Lajinha, Minas Gerais, using coffee strawGil Silva / Netzero

Two raw materials presented the best results: an aviary flooring material known as poultry litter, using rice straw or sawdust, bird feed remains and excrement; and ground sugarcane bagasse, known as filter cake, a residue of sugar and ethanol production in the form of fiber left over after pressing out the juice. The material is pyrolyzed at temperatures close to 400 degrees Celsius (oC) and then bathed in a solution with nitrogen, phosphorus, or potassium — the basic plant nutrients.

“The nutrients enter the pores and adhere to the surface of the biochar, which is then coated with a starch-based polymer,” explains Pereira Neto. Agronomic engineer Cristiano Andrade, of the Environmental Division of the Brazilian Agricultural Research Corporation (EMBRAPA), in Jaguariúna, inland São Paulo State, presents another possibility: “As it is very porous, biochar may also take on microorganisms that help plants to grow.”

Andrade coordinated field testing on 17 types of Carbosolo biochar, with nitrogen content between 3% and 38%, compared to urea, with up to 45% of this chemical element. Formulations with biochar proved to be more efficient, releasing nitrogen 60% more slowly. As described in a February 2020 article in the journal Science of the Total Environment, they provide gains of up to 21% in corn crop production, and 12% efficiency in nitrogen use by the plants.

Carbosolo and NetZero intend to stimulate regional biochar production in agriculture cooperatives or associations, using local raw materials to maintain low operating costs and final prices. Pereira Neto proposes an even more widespread decentralization: “Small farmers can also make biochar by using clay ovens and controlling the temperature.”

Pacheco acknowledges: “Biochar is a decentralized solution, with high degrees of flexibility from a geographical standpoint.” In a recent experiment, his group pyrolyzed cocoa fruit shells from the state of Espírito Santo, and was surprised to see that the biochar contained 70% potassium, an important nutrient for plants in dry mass.

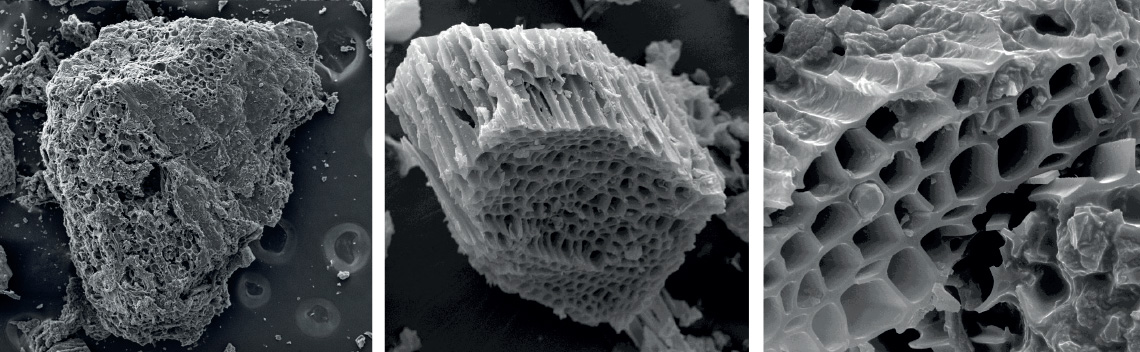

Carbosolo / Admilton Gonçalves de Oliveira Junior-UELScanning electron microscopy images: biochar from coffee grounds (enlarged 150x, left) and from eucalyptus (enlarged 800x, center, and 2,000x, right)Carbosolo / Admilton Gonçalves de Oliveira Junior-UEL

The oven needs to be well managed. “Air cannot be allowed to leak out or enter, because the extra oxygen not released by the raw material will burn instead of decomposing the material, and potentially form noxious compounds such as dioxins and furans,” warns Pacheco. According to Reinaud, the industrial process helps to control biochar pyrolysis.

“There is still a bottleneck,” says Andrade. “There is a lack of bigger ovens that can operate continuously with an endless feed, rather than in batches per the oven capacity.”

Initially doubting its potential benefits, Andrade began researching biochar in 2012, and was later convinced. With colleagues from the Campinas Institute of Agriculture (IAC), he confirmed that the material may also be useful for removing soil contaminants, as described in an article in May of this year in Environmental Geochemistry and Health.

Limitations

Environmental engineer Agnieszka Latawiec, of the Pontifical Catholic University of Rio de Janeiro (PUC-RJ) and the International Institute for Sustainability (IIS), says: “Biochar doesn’t work for everything all the time.” Its efficiency can vary according to the soil, climate, the plant cultivated, and the application method.

Aline Peregrina PugaApplication of biochar and soil preparation for crops in an experimental area of the Campinas Institute of Agriculture (IAC)Aline Peregrina Puga

In 2013, while still in Poland, she used biochar to fertilize corn. Output increased by 50%, even with degraded soil. Years later in Rio, she conducted a similar experiment with corn and beans at an experimental farm of the EMBRAPA Agrobiology Division in Seropédica, inland Rio State. According to a February 2018 article in the journal Sustainability, productivity gains were low, indicating that the results with biochar depend on a number of variables.

Supported by the Brazilian National Council for Scientific and Technological Development (CNPq) and the Rio de Janeiro Research Foundation (FAPERJ), experiments conducted by the group since 2014 have demonstrated that biochar use may bring about a 27% increase in the output of grasses used as cattle feed, as reported in an August 2019 study in Scientific Reports. Other tests gave different responses for each grass variety of the genus Brachiaria.

Over four harvests, biochar application resulted in better biomass production of the grass Capim-Paiaguás, a wild variety highly resistant to dry weather, followed by Piatã and, finally, Marandu — growth may be intensified in combination with forage peanut (Arachis), which facilitates the incorporation of nitrogen into the soil, according to a strategy detailed in this year’s September edition of the journal Agriculture, Ecosystems & Environment.

“After seeing the results, José Ferreira, the owner of the property on which we conducted the tests, said that he would continue with Piatã as he liked that variety,” says the researcher. “We talked a lot about what to do and improve. He always said: ‘I want my cows fat and my Sundays free.’ In other words, he is looking for an innovation that saves him extra work.”

Based on her field study, Latawiec makes certain recommendations: “Before large-scale application, it’s worth doing a pilot test, exposing the uncertainties to the agricultural producer, tracking the biochar, and monitoring its capacity to increase productivity and to sequester carbon, based on a cost-benefit and life-cycle analysis.”

Projects

1. Biochar carbon stability, soil aging process, and fertilizer effect of formulations with mineral sources (nº 17/02886-7); Grant Mechanism Research Grant; Principal Investigator Cristiano Alberto de Andrade (EMBRAPA); Investment R$90,766.09.

2. Agronomic and environmental efficiency of enriched and non-enriched biochar with a mineral source at supplying nitrogen (nº 15/21633-7); Grant Mechanism Postdoctoral Fellowship in Brazil; Supervisor Cristiano Alberto de Andrade (EMBRAPA); Beneficiary Aline Peregrina Puga; Investment R$271,512.95.

3. Biochar to improve the quality of soils contaminated with metals (nº 16/19368-6); Grant Mechanism Regular Research Grant; Principal Investigator Cleide Aparecida de Abreu (Agronomic Institute); Investment R$174,062.62.

4. Development of a biochar-based organomineral NPK fertilizer (nº 18/17194-6); Grant Mechanism Research Grant ‒ Innovative Research in Small Businesses (PIPE); Principal Investigator Braulio Garcia Pereira Neto (Carbosolo Desenvolvimento Agrícola Ltda.); Investment R$170,077.00.

Scientific articles

CARNIER, R. et al. Soil quality index as a tool to assess biochars soil quality improvement in a heavy metal-contaminated soil. Environmental Geochemistry and Health. Online. vol. 21. may 2023.

CASTRO, A. et al. The effects of Gliricidia-derived biochar on sequential maize and bean farming. Sustainability. vol. 10, no. 3, 578 pp. 1–15. feb. 26, 2018.

LATAWIEC, A. E. et al. Biochar amendment improves degraded pasturelands in Brazil: Environmental and cost-benefit analysis. Scientific Reports. vol. 9, 11993. aug. 19, 2019.

LATAWIEC, A. E. et al. Biochar and forage peanut improve pastures: Evidence from a field experiment in Brazil. Agriculture, Ecosystems & Environment. vol. 353, 108534. sept. 1, 2023.

MAIA, C. M. B. de F. et al. Efeito da temperatura de carbonização sobre características físico-químicas dos carvões de duas espécies de bambu. Brazilian Journal of Animal and Environmental Research. vol. 6, no. 1, pp. 817–25. mar. 30, 2023.

PUGA, A. P. et al. Biochar-based nitrogen fertilizers: Greenhouse gas emissions, use efficiency, and maize yield in tropical soils. Science of the Total Environment. vol. 704 135375. feb. 20, 2020.