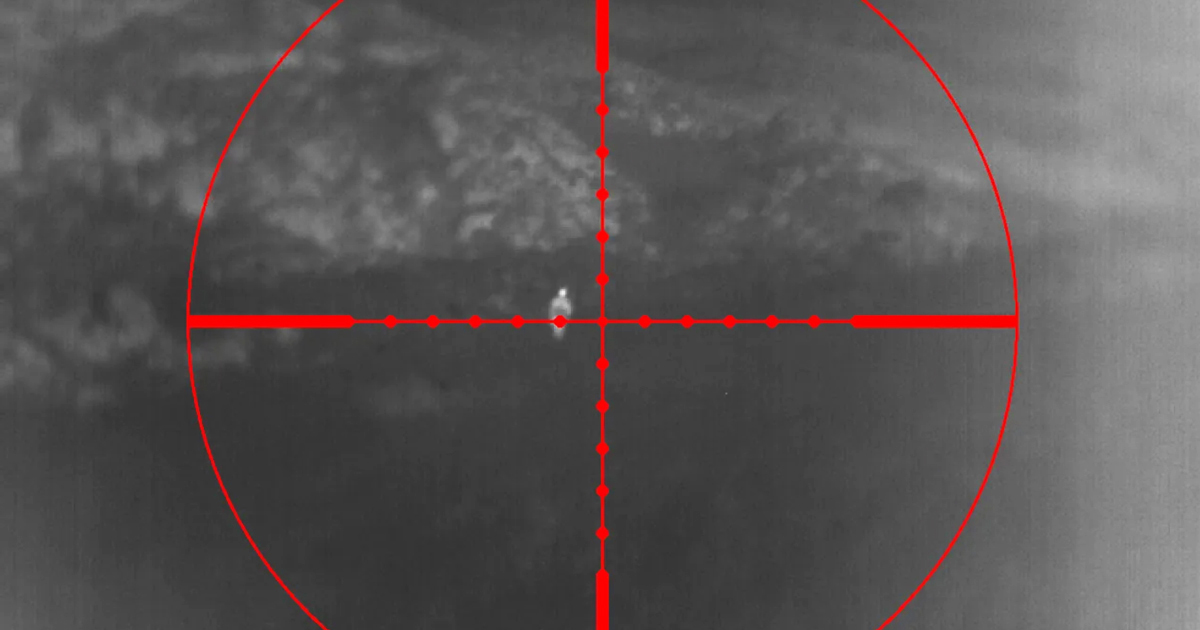

Brazilian ArmyImage captured by Olhar during Army equipment testsBrazilian Army

Opto Space & Defense, a Brazilian company under the Akaer Group that specializes in optronic systems, has developed an optical device that allows military, police, and security personnel to detect the presence of people, animals, facilities, and vehicles in poor lighting conditions, simply by sensing the heat they emit. Based in São José dos Campos, Akaer manufactures structures, equipment, and systems for the aerospace and defense sectors. The Olhar thermal-imaging monocular, the first of its kind developed by the Brazilian company, was designed based on requirements defined by the Brazilian Army. The first batch of 21 units was approved in August after more than a year of military testing.

“The Olhar was designed to be robust, lightweight, and small. This development shows that the country has thermal-imaging knowledge and can produce its own equipment. This grants us independence from the geopolitical issues that hinder the Brazilian Armed Forces from acquiring this equipment,” says electronics engineer Cláudio Carvas, CEO of Opto Space & Defense. The project, which began more than 15 years ago, was carried out in partnership with the Army’s Technology Center (CTEx) and was supported in its early stages by the Funding Authority for Studies and Projects (FINEP).

Fewer than 10 countries in the world, including China, the United States, France, Israel, and the United Kingdom, have mastered the technology for manufacturing thermal-imaging monoculars for military use—and those that do have this capability restrict marketing for the equipment.

“Thermal imaging is essential for those going to war. Defense experts often say that Brazilian soldiers are blind, because the war we see in the movies only plays out during the day. The real conflict takes place at night, when the difficulties are great and equipment like the monocular developed by Akaer is essential,” says physicist Jarbas Caiado de Castro Neto, of the São Carlos Physics Institute at the University of São Paulo (IFSC-USP), who was not directly involved in developing the equipment.

Devices such as the Olhar detect the infrared radiation associated with heat emitted by the human body or objects, converting it into a visible image. To do this, they are equipped with sensors, usually made of amorphous silicon or vanadium oxide, capable of capturing the thermal radiation emitted by bodies. The detected infrared radiation is converted into electrical signals that are processed to create a thermal image in which different colors or tones represent different temperatures. This image is displayed on a screen.

The monocular developed by Opto Space & Defense can be used not only in military operations, but also in rescue missions to locate people, animals, and hot objects in conditions with little or no visibility, such as smoky, dusty, or foggy environments. “The device detects hot objects in an image, whether it is day or night. That’s its main function,” says Carvas. “In most applications, the Olhar can be used to increase the user’s observation capacity.”

Weighing around 800 grams and measuring 155 millimeters (mm) long, 72 mm wide, and 67 mm high, the Olhar can be operated manually or mounted on helmets, rifles, and machine guns. Unlike most of its international competitors, the Brazilian device has two interchangeable lens options, with focal lengths of 14 mm (basic model) and 54 mm (Hunter model), which brings the image closer.

Brazilian Army Soldier wearing Opto thermal-imaging monoculars attached to his helmetBrazilian Army

Advanced model

Carvas explains that the Olhar differs from night-vision goggles. The US military used the latter in the mission to capture and kill terrorist Osama Bin Laden in Pakistan in 2011. “It’s not the same technology. Night-vision goggles are light intensifiers, which means they capture the minimal light in the environment and amplify it to form an image. The thermal monocular functions independent of ambient light.”

According to Akaer, which just this year became the first Brazilian aerospace company to achieve Tier 1 status as a global supplier (see sidebar), the monocular uses the most advanced microelectronics, precision mechanics, and optics. “The optical design of the thermal lenses and eyepiece guarantees high performance, which translates into images with high contrast and low distortion,” says the Opto Space & Defense executive.

In terms of electronics, small circuit boards were developed that contain components with very small enclosures. The device also features processing modules and a microdisplay using organic light-emitting diodes (OLED) and a high-resolution thermal sensor purchased abroad.

“For the mechanical structure, it was necessary to design and manufacture the monocular body at a small scale to accommodate the internal components and ensure their safety,” says Carvas. “The mechanical assembly had to ensure the optical alignment of the thermal sensor and the lens, otherwise the image would not have good resolution and sharpness.” The system’s robustness was another prerequisite established by the Army. The monocular can withstand 30 minutes in water and did well in the shock-resistance tests, according to Akaer.

“It’s a challenging technology,” says Castro Neto, from IFSC-USP, who helped design the first version of the monocular. Called the VDN X-1, it was initially designed in 2007 in the laboratories run by São Carlos startup Opto Eletrônica, of which the physicist was a cofounder. In 2016, the company’s Space & Defense (S&D) division was acquired by Akaer and renamed Opto Space & Defense. Three years later, the monocular project was relaunched.

Designing and manufacturing thermal-imaging lenses, as well as planning their electronics, is considered one of the most complex tasks by those familiar with the project. “Unlike lenses used for cameras in the visible spectrum, thermal lenses must be made from very specific materials, such as zinc sulfide, silicon, and germanium, the availability of which is limited. The optical system’s design is complex and must be engineered to eliminate chromatic aberrations, distortions, and other problems in order to obtain an accurate image,” says the USP researcher.

When contacted by Pesquisa FAPESP, the Army said in a statement that “the project was recently evaluated, and the equipment is still being studied for adoption.” During the technical and operational evaluation and approval process, several performance requirements were analyzed in the laboratory and in the field, according to standards compatible with those defined by the United States Armed Forces. The batch of 21 devices delivered to the Army last year was tested for electromagnetic susceptibility, noise emission, resistance to high and low temperatures, sand and humidity, among other things.

There is still no definite timeline as to when the monocular will be used in the field. “We don’t know how many units will be purchased or when. But we have already received inquiries from other countries interested in the equipment. However, sales abroad depend on the Army’s approval, since the project was commissioned by the Army,” says the Opto Space & Defense CEO.

Akaer has not revealed the price of the monocular. According to the company, the price will depend on a number of variables, such as the number of units included in the contract. Thermal-imaging monoculars already in use—such as those made by US companies Teledyne FLIR Systems and L3Harris Technologies, a supplier to the US Army, Britain’s BAE Systems, and Israel’s Elbit Systems—start at US$3,000 and can exceed US$20,000. The price varies depending on the device’s characteristics, the level of technological sophistication, the accessories, and other factors. “Olhar will be competitive. We won’t be the most expensive or the cheapest on the market,” says Carvas.

Deutsche AircraftD328eco: Akaer is responsible for manufacturing the front fuselage of the German turbopropDeutsche Aircraft

Akaer is the first Brazilian company qualified as a Tier 1 global supplier in the aerospace sector

In March of this year, Akaer, an engineering company from the São José dos Campos aerospace hub, in São Paulo, was selected by German manufacturer Deutsche Aircraft to design and manufacture the front fuselage of the D328eco, a 40-seat turboprop for regional markets. With the contract, the company became the first Brazilian Tier 1 global supplier in the aerospace sector, a goal it had been pursuing in recent years (see Pesquisa FAPESP issue n° 270).

“Akaer’s qualification as a Tier 1 global supplier is a milestone for the Brazilian aeronautics industry,” says economist Marcos José Barbieri Ferreira, of the University of Campinas’s School of Applied Sciences (FCA-UNICAMP), who specializes in the aerospace and defense industry. “Although we have the third largest aircraft manufacturer in the world, Embraer, we still didn’t have a Tier 1 company.”

He explains that companies with this capacity are Tier 1 suppliers of structural components, segments, and complex aeronautical systems, such as wings, fuselages (aerostructures), landing gear, engines, and avionics. Previously, Brazil only had Tier 2 and 3 companies, typically small and medium-sized suppliers of lower value components, such as machined parts or composites that make up larger structures.

The D328eco turboprop, intended for civil or military use, is being designed to fly on so-called sustainable aviation fuel (SAF), a solution being adopted by the aviation industry to reduce the sector’s carbon footprint (see Pesquisa FAPESP issues 317 and 337). Akaer estimates that the first fuselage manufactured in Brazil will be delivered by the end of next year. The aircraft is expected to enter commercial service in the fourth quarter of 2027.

Supersonic jet and rocket

The company based in São José dos Campos is participating in another major international project: construction of the Turkish supersonic military jet, Hürjet. The Turkish Aerospace Industry (TAI), the project’s leader, selected Akaer as its partner to develop and detail the structural design, structural calculations, and system installations for the rear fuselage, parts of the center fuselage, and empennage installations (rear surfaces) of the Hürjet. The first prototype made its maiden flight in April 2023.

“The biggest challenge we faced in this project was to revise the design and have all the documentation for the first prototype released in an extremely short space of time,” said Fernando Ferraz, vice president of operations, in a press release. “Overcoming this challenge was only possible thanks to extensive experience in developing complex aerospace products for the defense, executive, and civil aviation sectors.”

Akaer is also involved in strategic national projects, such as the revitalization of the Brazilian Air Force’s P-3AM Orion patrol aircraft and the development of a new small launch vehicle capable of launching nano- and micro-satellites into space.

Abroad, Akaer is taking part in an ongoing project, the Deep Underground Neutrino Experiment (DUNE), in the United States. Through its subsidiary Equatorial Sistemas and with the support of physicists from the University of Campinas (UNICAMP) and the Brazilian Center for Physics Research (CBPF), Akaer built one of the machines that will be used in the experiment (see report).

The story above was published with the title “Heat seeking” in issue 344 of October/2024.

Republish