Green pigment used in the photoreactor that conducts analyses with ultraviolet lighteduardo cesar

Under certain circumstances, light helps to speed up the processes of structuring and the decomposition of polymers. It also helps one to evaluate their composition. This close interaction and its many facets forms the basis of the studies carried out at the São Carlos Chemistry Institute (IQSC) at the University of São Paulo, which are yielding interesting results, especially in the field of dentistry. In the case of the resin composites used in dental treatments, one of the studies conducted focused on evaluating, with the help of ultraviolet (UV) lighting, the fluorescent response of dental restoration. In other words, the objective was to see whether it behaved like a natural tooth, which has its own fluorescence, thanks to a peptide called pyridinoline, found in dentin collagen.

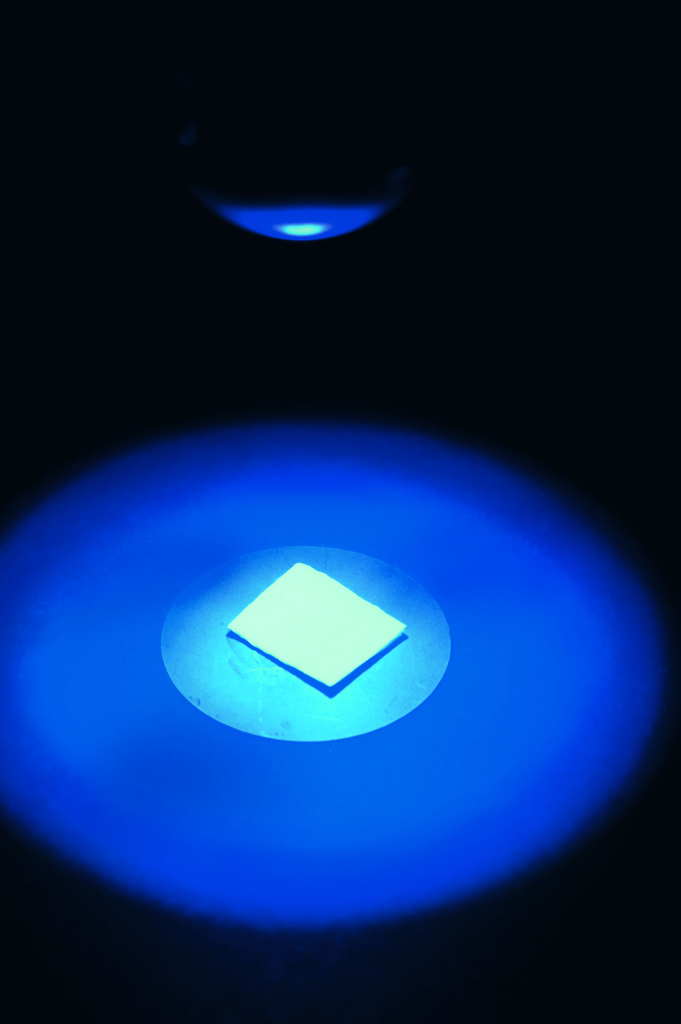

“Depending on the material used, the restoration appears to be black, whereas the tooth emits a bluish-white radiation in contact with UV light”, says professor Miguel Guillermo Neumann, coordinator at the University of São Paulo Support Chamber for Research Centers, who has been heading the IQSC Photochemistry Group since 1984, being responsible for the publication of more than 200 scientific works in national and international journals. “It’s as if there were a hole rather than a restoration”, compares professor Carla Schmitt Cavalheiro, Neumann’s partner in the research group.

The reason for this is that the resin’s composition may lack fluorescent agents, which in general are compounds of rare-earths and which are also used in a range of technologies such as fluorescent bulbs, glass and optical fibers. “When it comes into contact with UV radiation, the resin’s response must equal the tooth’s response”, says professor Ivo Carlos Correa, from the School of Dentistry at the Federal University of Rio de Janeiro (UFRM), who has been a member of the research group since 2000, when he began his doctorate at USP in São Paulo. “This is an important esthetic feature that must be taken into account in the material’s manufacturing process. “The study was presented at scientific congresses and drew the attention of a German enterprise that manufactures dental materials and adjusted its formulas to include the fluorescent component in the composition.

Yet another result of the IQSC research is a polymer photo-reactor, which is ready to go into production by order or even on a commercial scale. Also known as an irradiation chamber, the photo-reactor with 16 UV lamps was designed by researchers from the university and from Tecnal, a firm from the city of Piracicaba in inner-state São Paulo that is now producing the device. “We began developing this in 2003, based on a refrigerated chamber and, thereafter, we added the information found in scientific literature to the lab’s needs”, explains Fredy Rossi Borges, the firm’s sales manager. The firm has a research department staffed with engineers and technicians. Once this chamber was ready, the firm got an order from an UFRJ researcher to make another one like it. “We had to adjust the light wave length because the equipment was designed for other purposes”, says Borges. Other researchers’ interest in the product resulted in the creation of a catalog with photos showing the project’s variations.

Ultraviolet light reveals differences between restorationsINSTITUTO DE QUÍMICA DE SÃO PAULO/USP

The irradiation chamber is used in photopolymerization and photo decomposition studies. These are the two main photochemical areas studied at USP’s São Carlos campus. In the photopolymerization process, light is applied to very simply molecules, called monomers, to obtain more complex molecules, i.e., macromolecules or polymers, which are the basis for products such as dentistry resins, printed circuits, optical material, vinyl paints and plastics. In the dentist’s consulting room, the resins are in a liquid or paste-like state. This is the case of adhesives (a type of glue applied to the tooth to form the base coat for the restoration) and restoration composites, respectively. Photopolymerization is a process that hardens the material through the interaction of visible light and a dye, called a photoinititiator, that is involved in chemical reaction as a generator of free radicals.

In the dental area, the most often used photoinitiator is currently camphorquinone, a yellow dye that, when mixed with the formula, may cause the restored tooth to look yellowish; this becomes especially visible following whitening treatments. “For the restorations at the back of the mouth, this small difference isn’t very visible. But on the front ones it is harder to achieve the same tone as the other teeth and this difference stands out more after the teeth are whitened”, says Neumann.

Synchronous systems

In the search for whiter photoinitiators to replace camphorquinone, the industry faces an obstacle. “Depending on the source of light used for photoactivation, there is insufficient generation of free radicals to start the polymerization; as a result, the filling wouldn’t harden in the cavity”, explains Correa, from UFRJ. “The chemical system and the light system have to work in tandem”, highlights Carla. For the camphorquinone to kick off the polymerization process, for instance, it is necessary to apply a blue halogen or LED light.

Because of a controversy among the researchers regarding the capacity of LED light sources to polymerize dentistry materials, Correa chose this subject for his PhD thesis, presented at USP in 2003. “The blue light LEDs, a new lighting technology for dentistry, as opposed to halogen light, started to produce certain irregularities in the material’s resistance inside the mouth”, he tells us. Contrary to halogen lamps, whose light comes from incandescent filaments, LEDs convert electric energy directly into light by electroluminescence through bundles of semiconductors. Halogen light comprises a broader spectrum and is emitted in wavelengths of 350 to 700 nanometers, whereas LEDs emit a blue light of 440 to 490 nanometers.

Before beginning his doctoral thesis, Correa contacted Neumann and ever since, they have maintained a solid partnership, that is now going into its seventh year. “In collaboration with the professor, I worked on several combinations of resins, formulated with different initiators by Vigodent, a Rio de Janeiro firm, using halogen light and the LED provided by DMC Equipamentos, a company from the city of São Carlos”, explains Correa. The evaluation was conducted with four photoinitiators, including camphorquinone, PPD (phenyl propandione), and two photoinitiators made from acyl phosphine oxide: Lucirin TPO and Irgacure 819. “We concluded that depending on the photoinitiator used, one lamp works better than the other”, says Neumann. Lucirin, for instance, is more efficient than the other products assessed when it is irradiated with a conventional lamp, whereas camphorquinone responds effectively to LEDs. “We studied the chemical reactions that take place in less than one billionth of a second; with this, we can name the most efficient initiators”, explains Neumann.

Practical uses, however, depend on adjusting the commercial infrastructure, which is currently geared toward camphorquinone as the main photoinitiator in the formulations. Research into new photoinitiators may result in specific LEDs for these materials. “The efficiency of this process is important, because it will culminate in the longevity of the restoration”, says Correa. Some researchers are already focusing on developing sources with other light wave lengths for dentistry materials, besides blue. This study led to other research within the group, targeted at establishing phototonic efficiency parameters, such as more appropriate restoration material, light intensity, and wavelength band, capable of producing proper polymerization within the patient’s mouth. These studies had substantial impact on the global scientific community, during the presentation of the work of the photochemistry group at the International Association for Dental Research (IADR) congresses.

Tested degradation

Another one of the group’s lines of research that has been producing encouraging results is in the area of photodegradation, in which light is employed to decompose plastic discarded in companies, sanitary landfills and garbage dumps. The initial trials were carried out with polyethylene glycol, used in cosmetic formulas, skin ointments and car radiators, to control engine temperature. Pigments responsible for the start of photodegradation were added to these materials. Under certain circumstances, the polyethylene glycol decomposed into water and carbon dioxide molecules.

The studies were conducted by PhD student Laís Calixto Santos, who compared different methods of decomposition. One of them employed hydrogen peroxide and light; another, the Fenton reaction (a combination of hydrogen peroxide and iron salts); and a third one, the photo-Fenton system (hydrogen peroxide, iron salts and light). The iron salts behave like a pigment by absorbing light and initiating the reaction. The best result in terms of total consumption of the polyethylene glycol was achieved with the photo-Fenton system, used for about 15 minutes. With the irradiated peroxide, decomposition took two hours, whereas with the hydrogen peroxide and iron, without light, it took 10 days. This process can be used, for instance, to treat industrial effluents. In the future, these systems and others that include pigments may be used on plastic bottle formulations so that, when they are disposed of in the environment, the proess of decomposition is faster.

The Projects

1. Interaction of visible light with polymers: photopolymerization and photodegradation (nº 03/07770-4); Modality Theme project; Coordinator Miguel Guillermo Neumann – USP; Investment R$ 341,745.25 (FAPESP)

2. Contribution to the study of photostability of pigments in polymers (nº 05/03692-4); Modality Regular Research Awards; Coordinator

Carla Schmitt Cavalheiro – USP; Investment R$ 244,184.88 (FAPESP)

3. Photoinitiated vinyl polymerization (nº 98/11752-1); Modality

Global aid; Coordinator Miguel Guillermo Neumann – USP; Investment R$ 34,000.00 (CNPq)