Brazil’s first automated device for collecting soil hydrology data will make its debut in early 2025. The new permeameter—a device that measures the rate at which water moves through waterlogged soil, a parameter known as saturated hydraulic conductivity—was developed through a partnership between the Brazilian Center for Research in Physics (CBPF) in Rio de Janeiro, the Brazilian Agricultural Research Corporation (EMBRAPA), and Falker, an agricultural technology (AgTech) firm based in Rio Grande do Sul. Featuring a low-cost microcomputer, the device is described in detail in a 2019 paper in the Journal of Hydrology.

Saturated hydraulic conductivity measures the ease with which soil transmits or drains water—a useful measure in applications ranging from sustainable agriculture to infrastructure design. By integrating this data into irrigation systems, water use can be optimized to suit the soil’s characteristics, reducing waste and mitigating erosion risk. Knowing how quickly water will percolate into the soil is also useful in designing road drainage systems, calculating aquifer recharge, developing landfills and dams, and guiding disaster mitigation efforts such as landslide prevention.

“As extreme weather events like torrential rains and severe droughts become more frequent, understanding soil-water dynamics will be crucial for planning in both the public and the private sector,” says Wenceslau Teixeira, an agricultural engineer leading soil research at EMBRAPA’s Rio de Janeiro unit.

Teixeira underscores a key gap in Brazilian soil research: a lack of knowledge about the hydraulic properties of local soils. He explains that Brazil’s tropical soils—particularly clay-rich ones—display water behavior patterns that differ significantly from temperate soils, such as those found in the US and Europe. “We need reliable, nationally sourced data to stop relying on values and models calibrated for other countries, which apply to completely different soil types,” he stresses.

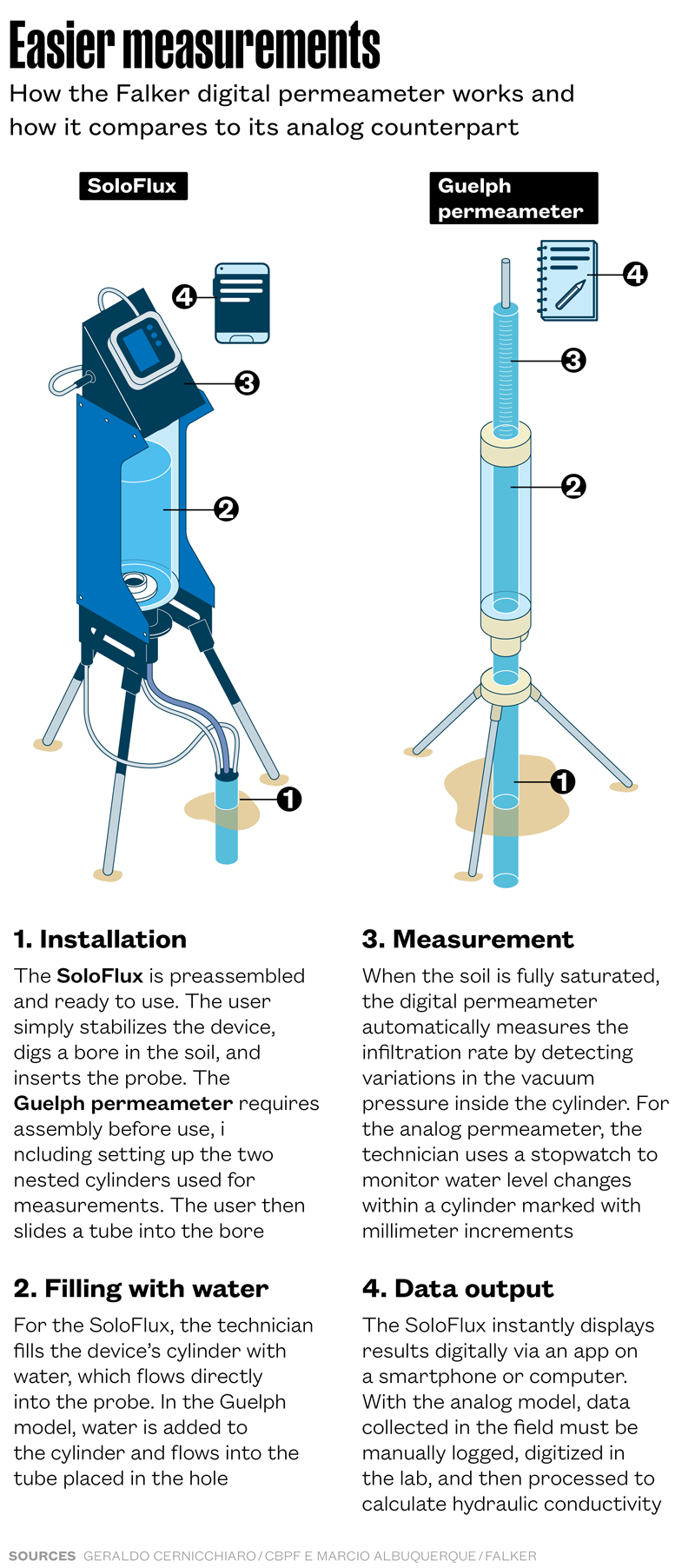

The key breakthrough of the new permeameter, dubbed SoloFlux and in development since 2018, is its ability to automate and digitize data collection. Currently, measuring saturated hydraulic conductivity involves using an analog permeameter that requires manual data collection and calculations by a highly trained technician. One of the most widely used devices worldwide is the Guelph permeameter, an analog model developed in the 1980s at the University of Guelph in Canada. Because it is imported, the Guelph model demands complex field assembly—a problem the SoloFlux eliminates entirely.

The test process begins with digging a small bore in the soil, about 20 centimeters (cm) deep and 6 cm in diameter. The analog permeameter operates through a system of two cylinders nested within each other, designed to maintain a constant water level in the bore. As water infiltrates the soil, the device measures the percolation rate. The technician manually records these readings in a notebook during the test. Once in the lab, the data is digitized and processed to calculate the soil’s hydraulic conductivity (see the infographic below).

“We’ve simplified and automated the process. Our permeameter measures the vacuum pressure that sustains the water column within a single cylinder. Variations in this vacuum correspond to changes in the water level, enabling us to more accurately quantify the flow of water into the soil,” explains electrical engineer Geraldo Cernicchiaro, who led the research at CBPF. The device generates real-time data during measurements, which can be transmitted via Bluetooth to the Falker Flow app on a smartphone, tablet, or computer. The immediate availability of field data allows researchers to retake measurements or expand the sampling area on the spot if needed.

This capability to analyze a larger area during a single field visit is a significant advantage, according to agricultural engineer Claudinei Fonseca Souza, an irrigation and drainage specialist. “We typically spend about two hours taking measurements at a single point. With this new permeameter, which appears faster and simpler to use, we could collect more samples in the same time frame. Because soil properties vary greatly even over short distances, a reading taken at one point might not reflect the conditions just 10 meters away,” Souza explains. A professor in the Department of Natural Resources and Environmental Protection at the Federal University of São Carlos (UFSCar), Souza was not directly involved in the development of SoloFlux.

In addition to improving speed and expanding measurement coverage, the ability to both read and analyze data in the field has the potential to significantly cut costs. With analog models, technicians need to return to the lab to digitize and process the data. Any errors in collection could render the fieldwork useless, requiring them to return to retake measurements. During his undergraduate years, Souza recalls a frustrating experience with a conventional permeameter: he stumbled onto a burrowing armadillo’s hole, which forced him to redo the entire procedure. “Now imagine realizing there’s an issue with your data collection only after you’ve returned to the lab. What if the lab is in another city? That’s wasted time and money,” he points out.

Falker CEO Márcio Albuquerque is confident the new device’s user-friendly design will help increase adoption. “For the device to achieve commercial success and widespread use, it’s crucial that it delivers results quickly,” he explains. Albuquerque highlights that the new permeameter is a world first. “In our research, we found only one similar device in Europe, which is still transitioning from research to a market-ready product, primarily for sanitation applications.”

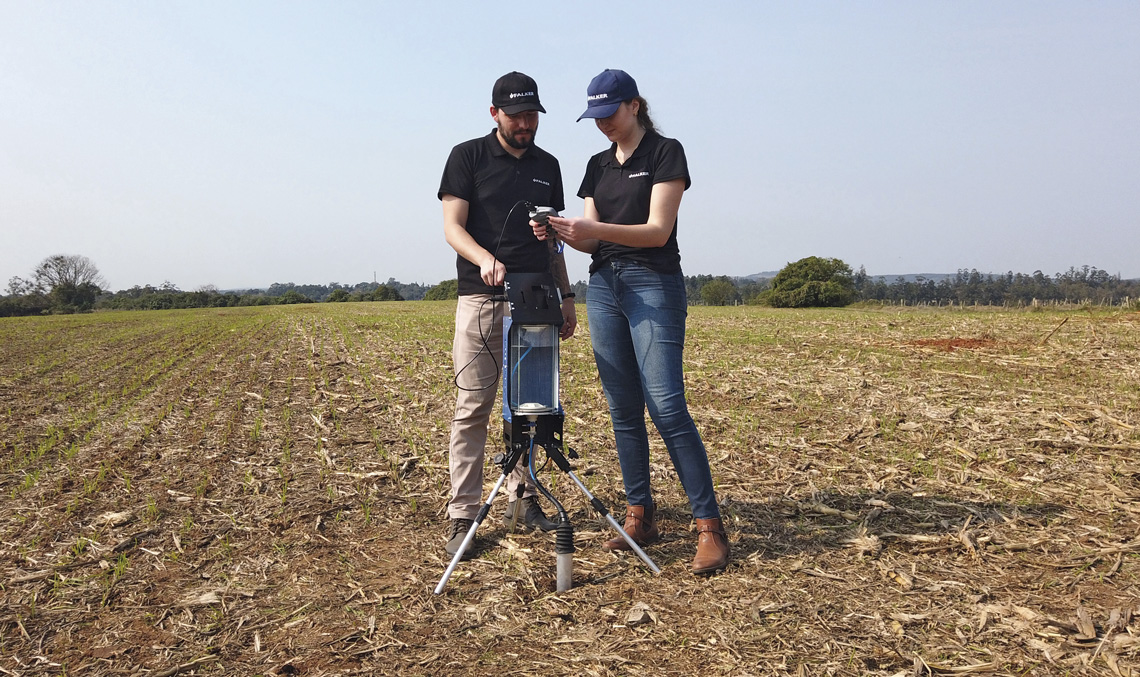

FALKERTechnicians conducting field tests with the digital permeameterFALKER

Falker, founded in 2005, produces a range of precision agriculture devices. The company is currently conducting field tests of the new permeameter with farmers from a cooperative in Paraná. “Our partner is using the device to enhance soil conservation,” Albuquerque adds.

The digital permeameter is the first CBPF-developed innovation to reach the market. While CBPF primarily focuses on basic research, it has recently increased efforts to translate its studies into practical innovations. Alongside EMBRAPA, CBPF holds the patent for the electronic device used to digitize the saturated hydraulic conductivity measurement process, as well as the associated algorithm. The measurement system, which differs from that of the Guelph permeameter, was developed in collaboration with Falker and is protected as a registered design.

“The approach to developing this new permeameter is a prime example of open innovation. It starts with research conducted at a research institution, followed by collaboration with a private company that helps develop and market the technology,” says Gizelle Bedendo, a chemist who heads the Technology Transfer department at EMBRAPA Solos.

As part of the agreement between the three partners, Falker is required to pay royalties to both EMBRAPA and CBPF. The agreement also includes a clause for reviewing the royalty rate two years after the equipment is commercially launched. Albuquerque notes that SoloFlux will be priced at about half the cost of analog permeameters currently on the market. The Guelph permeameter, for instance, costs approximately R$70,000. Falker also plans to export its digital permeameter, with international shipments expected to begin by the first half of 2025.

The story above was published with the title “Breaking ground on soil permeability” in issue 346 of December/2024.

Scientific article

CERNICCHIARO, G. et al. Digital interface device for field soil hydraulic conductivity measurement. Journal of Hydrology. Vol. 576, pp. 58–64. Sept. 2019.

Republish