One initiative of the Brazilian National Confederation of Industry (CNI), implemented by the National Service for Industrial Training (SENAI), is creating new perspectives for research and innovation for Brazil’s production activities. The initiative is building a network called SENAI Institutes of Innovation (ISIs). Today, there are 21 entities in operation, employing 550 researchers, 40% of whom have a master’s or doctorate, and which have generated more than 500 research projects of industrial interest since 2013, the year when the first entities began operation. Five more are expected by 2021.

The ISIs were conceived in 2011 and began implementation in 2013. The idea came from a group coordinated by CNI called Mobilization for Business Innovation (MEI), which brings together close to 200 executives from large companies operating throughout the country (see Pesquisa FAPESP issue no. 266). The objective is to establish centers of research and development (R&D) that have the capacity to support industry in the task of seeking innovative products and production processes in order to compete.

“Brazil once had a significant industrial park. But after the external debt crisis of the 1980s, it stopped investing and lost its land. China, India, and South Korea invested in industrial development and became powerful. We needed to take action,” says Rafael Lucchesi, general manager of SENAI. For Lucchesi, the global times for industry, with the 4.0 revolution, could be fatal for companies that are not innovating or synchronized with today’s models of production. However, industries with lower global reach, like that of Brazil, have difficulty maintaining a technical team and an adequate infrastructure dedicated to innovation.

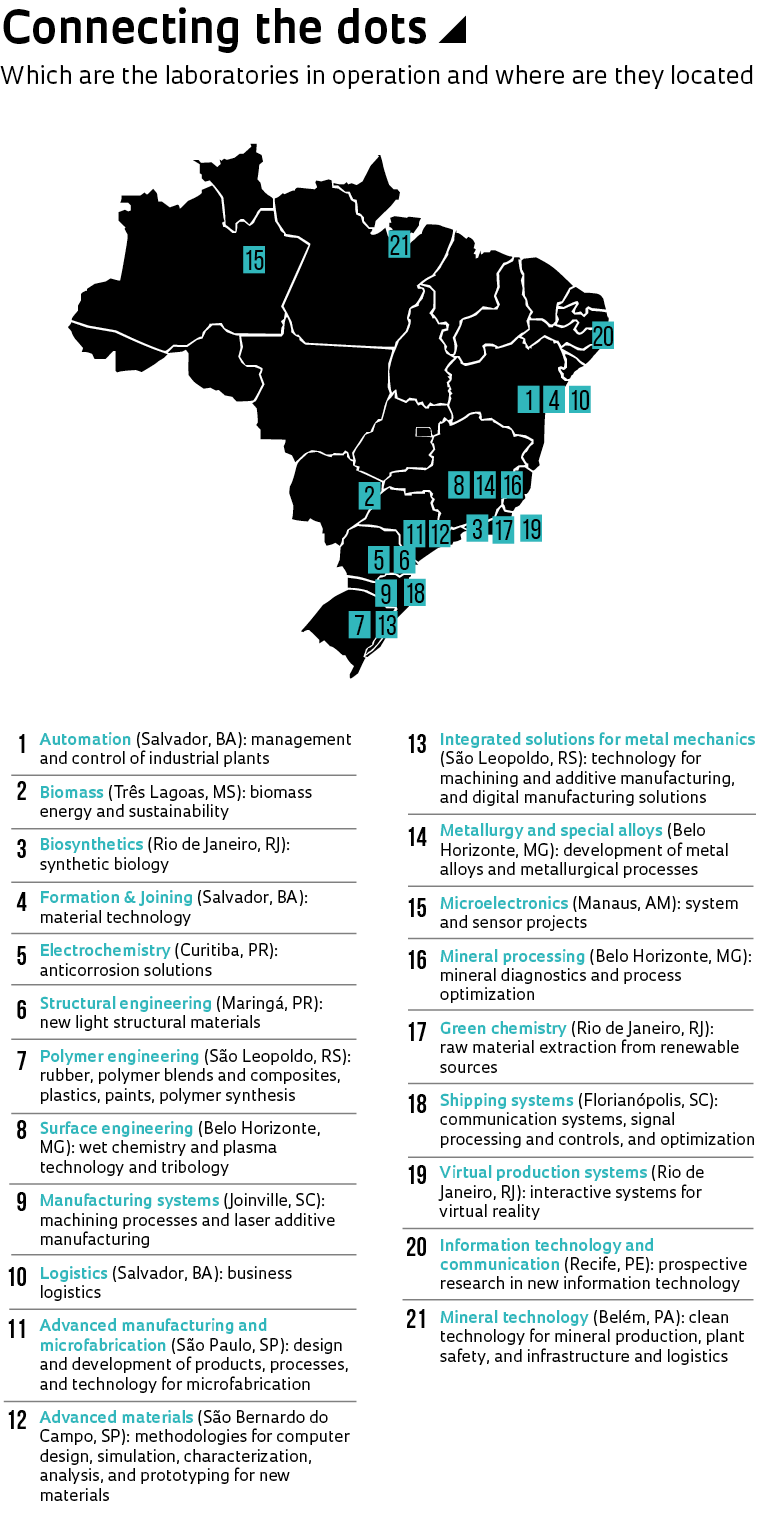

The ISIs emerged to fill this gap, says Lucchesi. The model adopted by the institutes was inspired by the Fraunhofer Society of Germany, a benchmark organization in applied research in Europe. Specialists from Fraunhofer IPK in Berlin were in Brazil to assist with the planning and implementation of each ISI entity, focusing on the market and today monitoring their performance. The Massachusetts Institute of Technology (MIT) was contracted to assess the Brazilian innovation ecosystem. Each SENAI institute has a theme focus that reflects a global production trend, such as automation, advanced manufacturing, shipping systems, logistics, green chemistry, information technology, and communication (see complete list), and is located close to industrial complexes and universities.

The institutes offer solutions to local and national needs and, despite geographical distances, they were developed to work in an integrated manner. The challenges put forward by the companies are addressed in a multidisciplinary format, by a network of researchers and laboratories. Using a scale of project technological maturity—the Technology Readiness Level (TRL), which is between 1 (basic research) and 9 (product on the market)—the focus of the ISIs is to work in the intermediate stages, from product conception for new products and applications, experimentation and validation, to the prototyping phase and pilot production for new products.

Investments in the 21 operational institutes total R$2.5 billion; another R$500 million has been set aside for five new entities scheduled to launch by 2021, totaling R$3 billion. Half of this funding, R$1.5 billion, comes from the Brazilian Development Bank (BNDES) and the other half from CNI/SENAI system resources. In the case of BNDES, a loan is made to SENAI with a grace period of three years, and amortization of 12 years.

Among the new institutes, two should begin operation in 2019. One is in the area of engineering and civil structures in Paraná, and the other in renewable energy in Rio Grande do Norte. Three others are planned to start in 2021—in biotechnology in São Paulo, inspection and integrity in Rio de Janeiro, and electricity and electronics in Itajubá, Minas Gerais State. Marcelo Prim, manager of innovation and technology for SENAI, reports that 25% of the 500 projects already contracted by the ISIs were developed in partnership with universities. The most recent include the University of Campinas (UNICAMP), University of São Paulo (USP), the federal universities of Pernambuco (UFPE), Santa Catarina (UFSC), and Rio de Janeiro (UFRJ), the Aeronautics Institute of Technology (ITA), and the Oswaldo Cruz Foundation (FIOCRUZ).

The challenges proposed by companies are analyzed by a network of researchers and laboratories

“The ISIs have cutting edge infrastructure and sophisticated technical teams, and with the respect of renowned research institutions, they have opportunities for technological collaboration as required. They have proven their capacity to present solutions to companies,” says Ricardo Alban, president of the Federation of Industries for the State of Bahia (FIEB). The investment in the projects commissioned by the ISIs exceeds R$500 million, with half of the resources coming from large-scale companies involved in 30% of innovation development. The medium-sized companies represent 20% of the projects and 30% of the resources, while small companies and startups are responsible for 50% of the projects and 20% of the resources.

Eleven of the 21 institutes are certified as entities of the Brazilian Agency for Industrial Research and Innovation (EMBRAPII). To obtain this certification, they were required to prove their ability to raise more than R$25 million per year in projects. The support of EMBRAPII is in the form of shared funding, where one-third comes from the federal agency, the equivalent from the company, and the last third from the ISI. The latter normally contributes the equivalent in laboratory time and human resources, rather than financial support.

According to Marcelo Prim, the innovation projects arrive at the ISIs via two main tracks. One track is when a large or medium-sized company presents a problem and expects suggested solutions. The other, which represents 50% of the projects, are ideas that arise in startups and small companies that require both support to develop the solution, as well as finding a market for the innovations. “It is common for our researchers to create a bridge with large companies that are potential clients for the solution,” he says.

Léo Ramos Chaves

Reciclapac packaging, São Paulo: support of two ISIs for technology development

Léo Ramos ChavesPackaging and nanosatellites

Rogério Junqueira Machado created the startup Reciclapac, which was born at the Center for Innovation, Entrepreneurship and Technology (CIETEC-USP) in São Paulo, with the purpose of developing returnable and trackable packaging for the transportation of parts between industry and suppliers. “A lot of packaging is thrown away due to the breakdown of the material used or simply because companies do not employ adequate processes to manage their reuse,” he says. Machado’s idea was adopted by two SENAI institutes. The ISI Advanced and Nanocomposite Materials of São Bernardo do Campo (São Paulo) helped him to develop durable packaging made of recycled plastic.

The ISI Information and Communication Technologies (TIC) of Recife supported Machado in the development of an intelligent tracking solution using an internet of things (IoT) platform. “It is a system that facilitates monitoring of the entire supply chain with precise information that supports production planning,” says Sérgio Soares, director of ISI-TIC.

The smart packaging of Reciclapac was launched in January 2018 and is currently in the concept-testing phase in companies such as General Motors, Cebrace (of the Saint-Gobain group), Nissan, and Júlio Simões Logística. “It is a global innovation that is being very well received, including in presentations we have made in Germany,” says Machado. Reciclapac also received support from FAPESP’s Innovative Research in Small Businesses (PIPE) program.

In Santa Catarina, the ISI Shipping Systems was chosen to partner with Visiona Space Technology in the development of technology and testing of the first Brazilian nanosatellite—equipment with dimensions in centimeters of 10x20x30 and weighing 10 kilograms, while traditional equipment could reach several tons. The project budget is R$7 million and one-third of the funding will come from EMBRAPII.

José Paulo Lacerda / CNI

Researcher from the ISI Shipping Systems in Florianópolis, which develops technology for a Brazilian nanosatellite

José Paulo Lacerda / CNIVisiona integrates space systems and is the result of a joint venture between Embraer Defense & Security and Telebras. João Paulo Campos, company president, reports that the company is striving to control all onboard software for satellites, with a focus on the system for orbit control and equipment attitude. “This is the most protected space technology in the world and Brazilian satellites have always been equipped with imported products,” he says.

Three systems are fundamental for this: one for orbit and attitude control; one for onboard data management; and the ground control system. “We will authenticate software development on the workbench, during the integration of satellite subsystems, and also in flight, through the use of Data Collection Platforms that will be developed and distributed across the country. And lastly, the development and construction of the satellite ground control and tracking station,” explains Herivaldo Maia, lead researcher for the project of the ISI Shipping Systems.

According to Campos, the nanosatellite will authenticate developed technologies and establish the security necessary for the use of large-scale satellites. The launch of the nanosatellite is planned for the first half of 2020.

Brazil invests close to 1.2% of GDP in R&D, half of that spent by developed nations

Science and industry

The study announced in March of this year, and carried out by MIT at the request of SENAI, showed that Brazil invests about 1.2% of its gross domestic product (GDP) in R&D. Half of the funding comes from public sources and the other half—managed by private companies—is represented by expenses that are, for the most part, funded by the government. According to data from the Organisation for Economic Co-operation and Development (OECD), its most developed member nations represent a total average R&D expenditure of 2.4% of GDP, with 1.65% coming from the corporate sector and 0.75% from government.

Marcelo Prim claims that the innovation scene in Brazil has been historically shrouded with uncertainty regarding public policy (which is often subject to change) and the availability of economic incentives. “Industrial innovation is long-term investment. In Brazil there is no predictability, so investment is curtailed and industry retracts,” he confirms. Prim says that the CNI proposal is to offer stable programs that are comprehensive, far-reaching, and encourage innovation that interests the production sector.

One example of this is the Industry Innovation RFP, which has been running without interruption since 2004. The grants have already supported 947 projects, 42% of which have had their products or services get to market. For Prim, the results are very positive, since the world average impact for similar programs is between 30% and 40%.

In 2018, the RFP is being carried out by SENAI in partnership with the Social Service for Industry (SESI) and the Brazilian Micro and Small Business Support Service (SEBRAE). In early 2019, the close to 120 projects will be revealed and will receive a total of R$55 million. The chosen projects will receive various levels of support that could reach R$600,000.

A complex with a focus on the future SENAI and SESI plan to build a structure in Brazil to coordinate the Institutes of InnovationThe National Service for Industrial Training (SENAI) and the Industry Social Service (SESI) are planning to build a complex in Brasília (Federal District) with a focus on innovation. The idea is to bring together, in an area of 85,000 m2, environments that are geared at supporting and communicating the culture of research and of technological development with a focus on manufacturing activities. Named the SE Complex – SESI SENAI, operation is set to begin in the second half of 2021.

The estimated total investment is R$500 million.

One of the key activities to take place within the complex is the national coordination of the 26 SENAI Institutes of Innovation (ISIs) and of the eight SESI Centers of Innovation that develop solutions in health and work safety. Gustavo Leal, director of operations for SENAI National, explains that the management of the ISI network will be tasked with establishing dialogue with each one of the 28 sectors that comprise national industry, with the objective of mapping out urgent sectoral needs over a three-to-five-year timeframe, and the technology that can meet these needs.

The next task for management will be to investigate which Institutes of Innovation satisfy the identified needs and then establish a plan for servicing sectoral demands. “We will have the flexibility to see the needs and adapt the abilities of the ISI network, encouraging collaboration or building new units if necessary,” confirms Leal. The idea is that management be capable of addressing the challenges presented by corporate leaders. To achieve this, SESI and SENAI are seeking partnerships to develop their work methodology. There have been conversations with the Institute for the Future of Palo Alto, California, a think tank with the mission of supporting organizations to plan for the future, and with the Massachusetts Institute of Technology (MIT).

In a second phase of the project, the knowledge acquired through dialogue and the search for technological solutions for industry will be used to develop conversations with society in order to put forward possible solutions to national problems, such as public safety, urban mobility, and sanitation. The SE Complex – SESI SENAI will also be a center for the development of new educational technology to be used in the SESI and SENAI networks and a Corporate University, which will be responsible for talent development for both institutions, the National Confederation of Industry (CNI), and state federations. It will also house a convention center and an interactive museum to allow visitors to try various forms of exploring scientific and artistic knowledge. “It will be a museum that will replace the signs ‘do not touch’ with ‘please touch everything,’” jokes Leal.

Republish