Bárbara MalagoliSome manufacturing companies have started using a new business model for their products. Traditional sales are being replaced with a commercial system in which companies retain ownership of the goods they produce, take care of maintenance and guarantee functionality, while customers pay to use the features offered by the product. This is called a product-service system (PSS), “product as a service” or servitization, a word used to define the strategy of a product supplier switching over to a PSS solution.

Bárbara MalagoliSome manufacturing companies have started using a new business model for their products. Traditional sales are being replaced with a commercial system in which companies retain ownership of the goods they produce, take care of maintenance and guarantee functionality, while customers pay to use the features offered by the product. This is called a product-service system (PSS), “product as a service” or servitization, a word used to define the strategy of a product supplier switching over to a PSS solution.

Many examples already exist in other countries, particularly in Europe. Rolls-Royce offers its aircraft motors through a PSS model that has airlines paying per hour of flight. Michelin offers truck fleet managers a system in which the company is compensated according to mileage driven on its tires. In the Netherlands, Philips analyzes the business settings of corporate clients and designs their lighting accordingly. Clients are billed for lighting in hours used, paying a fee that includes everything from installation and equipment to maintenance.

BMW uses its DriveNow service to offer use of its vehicles in 12 cities in Europe, including Berlin, Vienna, London, Copenhagen, Stockholm and Milan. In Copenhagen, for example, 400 BMW vehicles are available through DriveNow. Pricing is based on hours of use, and includes fuel and insurance. The service is accessed via mobile app. The city of Vancouver, in Canada, has four competitors with the same kind of offering, known as car-sharing: Zipcar, car2go, EvoCar and Modo. Zazcar also applies this business model in Brazil, in the city of São Paulo. In the United States, General Motors launched Maven, a short-term rental service developed for drivers no longer willing to accept the fees, insurance costs, work and expenses involved in owning a vehicle. According to consulting firm McKinsey & Company, car-sharing and similar services will represent a US$1.5 trillion market by 2030.

PSS customers receive added services aside from the mere use of a product, setting the model apart from options like renting–which does not include maintenance–or leasing, a type of financial lease in which a client can use a product while making monthly payments, not involving the cost of services, and then has the option of purchasing the product at the end of the contract.

Bárbara MalagoliIn Brazil, some manufacturing companies are also shifting to servitization. One example is Whirlpool, which has chosen not to sell its Brastemp-branded water purifier. The company installs the equipment in its customers’ homes, takes care of maintenance, replaces filters and charges a monthly subscription. Another example is IBM, which used to sell computers and software and now works jointly with Brazilian companies to develop an online reference platform for agribusiness data and solutions. Customers of IBM AgriTech pay for the information obtained, such as real-time weather forecasts and recommendations as to best dates and times for planting, fertilizing and irrigating. “The applications within this platform are consumed as services, without considering the computer infrastructure. The service is priced according to what is processed. For instance, for crop images generated by a drone, pricing is based on the image size requested by the customer,” explains Ulisses Mello, research director at IBM Brazil. He believes that the solution developed in Brazil has a global vocation and will likely be taken to other countries.

Bárbara MalagoliIn Brazil, some manufacturing companies are also shifting to servitization. One example is Whirlpool, which has chosen not to sell its Brastemp-branded water purifier. The company installs the equipment in its customers’ homes, takes care of maintenance, replaces filters and charges a monthly subscription. Another example is IBM, which used to sell computers and software and now works jointly with Brazilian companies to develop an online reference platform for agribusiness data and solutions. Customers of IBM AgriTech pay for the information obtained, such as real-time weather forecasts and recommendations as to best dates and times for planting, fertilizing and irrigating. “The applications within this platform are consumed as services, without considering the computer infrastructure. The service is priced according to what is processed. For instance, for crop images generated by a drone, pricing is based on the image size requested by the customer,” explains Ulisses Mello, research director at IBM Brazil. He believes that the solution developed in Brazil has a global vocation and will likely be taken to other countries.

Xerox in Brazil has also launched a pay-per-print service, where it takes responsibility for the maintenance and management of materials. For decades, the company has sold or leased its machines. JBT, a machine manufacturer for the citrus industry, has developed a business model in which the company provides orange processing services. It charges per metric ton of oranges processed.

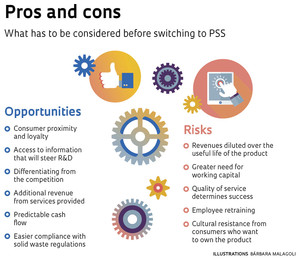

Production engineering researchers believe that PSS can create a new industrial paradigm. Many companies today apply product strategies involving planned obsolescence, i.e., products are purposely designed to have low durability and thus force the consumer to buy again sooner, driving sales and production scale. PSS makes product durability desirable for companies. The longer a product’s useful life, the higher the earnings. “Companies will need to change the focus of their business. Instead of quantity, their objective will be to design products with higher quality and durability,” says technologist Fernanda Hänsch Beuren, a professor in the production engineering course at Santa Catarina State University (UDESC).

PSS is also a more eco-efficient process. The manufacturer knows better than anyone the characteristics of its products and the factors that will increase its useful life. Michelin was able to increase the average usage period of the tires it offers under PSS contracts by 2.5 years, through adequate maintenance. Products with a longer useful life are discarded at a slower rate. Therefore, companies will produce less and demand fewer raw materials and inputs.

At the end of a product’s useful life, disposal is not left at the hands of the consumer, who often does not have enough information or interest in discarding the material correctly. Because they retain ownership of products, manufacturers will tend to repurpose materials and inputs into remanufacturing processes and, when necessary, arrange for a more organized and environmentally correct disposal of components that have become obsolete. “This is an important support for the transition from a linear economic model of extraction, processing and disposal of inputs to a circular economy of sustainable repurposing,” says mechanical engineer Henrique Rozenfeld, a professor at the São Carlos School of Engineering (EESC-USP).

Bárbara MalagoliSwitching to a PSS model can benefit companies in many ways. The system generates additional and recurring revenues through continuous provision of services. It drives loyalty and a stronger bond with customers, enabling the supplier to better know their demands and consumption habits, information that will steer innovation and the development of new market solutions. It is also a strategy for differentiating a product from others on the market and facing the competition imposed by price.

Bárbara MalagoliSwitching to a PSS model can benefit companies in many ways. The system generates additional and recurring revenues through continuous provision of services. It drives loyalty and a stronger bond with customers, enabling the supplier to better know their demands and consumption habits, information that will steer innovation and the development of new market solutions. It is also a strategy for differentiating a product from others on the market and facing the competition imposed by price.

According to Rozenfeld, servitization can potentially reverse the deindustrialization process in low production scale economies, like Brazil. “The local industry does not have a cost structure that can compete against companies that operate with large global volumes, but it can add value to its products and set itself apart through the quality of services provided and through customization,” he says. This is exactly what the German capital goods industry has been doing to face off against its Asian competitors, which offer machines at a lower initial cost.

PSS also offers advantages for consumers. The first is that they do not need to pay immediately to use a product and the costs are diluted over the period of use, in some cases even permitting access to more sophisticated goods. Consumers also cut the risks associated with ownership, like regret, depreciation and obsolescence. In addition, they don’t need to worry about maintenance and upgrading, or even post-use disposal. But PSS is not necessarily a cheaper option for consumers. The product-service system is convenient for customers because of perks like guaranteed maintenance and no need for the full upfront payment required by a direct-to-consumer sales system. It is difficult to calculate whether the amount paid in the long term will be higher than the price of an immediate purchase. “The available studies indicate that it can actually be lower because by acquiring a product in the traditional way, the customer will pay for maintenance and any added costs,” says Rozenfeld.

Business administrator Glauco Henrique de Sousa Mendes, a professor in the Production Engineering Department at the Federal University of São Carlos (UFSCar), says that in business-to-business (B2B) markets, where PSS is currently more common, corporate clients not only reduce their need to invest in assets, like machines, but they also receive integrated and customized solutions for specific areas of their business, enabling them to focus resources on core processes.

The PSS concept has only recently become more disseminated–it was created around 10 years ago–and has been gaining shape in the B2B markets of countries like Germany, the United States and Denmark. Mechanical engineer Eduardo Zancul, a professor at the University of São Paulo Polytechnic School (Poli-USP), says that PSS gains momentum by offering answers for macrotrends in society, such as an increased concern for the environment and a drive for sustainable development. It also reflects the start of a cultural shift towards a shared economy that values the use, and not necessarily the ownership, of a product.

The PSS concept has only recently become more disseminated–it was created around 10 years ago–and has been gaining shape in the B2B markets of countries like Germany, the United States and Denmark. Mechanical engineer Eduardo Zancul, a professor at the University of São Paulo Polytechnic School (Poli-USP), says that PSS gains momentum by offering answers for macrotrends in society, such as an increased concern for the environment and a drive for sustainable development. It also reflects the start of a cultural shift towards a shared economy that values the use, and not necessarily the ownership, of a product.

“The PSS model still involves many challenges that need to be overcome for it to become more widespread. The first is that ownership culture is still prevalent and difficult to reverse, especially in consumer-oriented markets,” says Mendes. Another problem is how to design the business model. Financial engineering is a key issue. In a traditional commercial model, the manufacturer is compensated in the short term after selling its product. In PSS, the manufacturer earns more money by offering a product plus services, but that compensation is slow, diluted over the course of the product’s useful life, increasing the need for working capital. “In a country like Brazil, where the cost of money is high, this is a major obstacle,” says Zancul. In seasonal markets, there is an advantage for manufacturers because systems or products currently in use will guarantee a recurring and constant income during a sales slump.

Mendes from UFSCar says that some important organizational barriers need to be overcome. “Industrial companies will have to develop new capabilities and processes,” he says. One example: a company that switches to PSS will have to develop longer-lasting relationships with customers and enhance its service support structures. Consumers will take into account not only the quality of the tangible product, but also and primarily the quality of services provided, including reliability, safety and customer care. “Companies that switch to PSS and provide low-quality service will have a hard time sustaining their business models.”

There is also an impact on the job market. Companies will hire more service employees and will have to offer training to make sure that their services truly meet the expectations of consumers. Beuren from UDESC believes that PSS will encourage companies to work as a network, operating jointly with specialized companies across the production and commercial chain, from design and production to customer care. “It is very hard for a company to successfully specialize in all stages of the process. It is easier to outsource and to bring specialized partners into the business cycle,” she says.

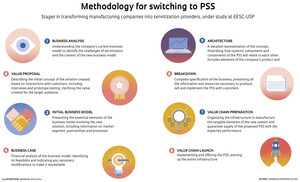

Understanding the risk and success factors of PSS and developing techniques and methods to help companies adopt the system are issues currently being studied by production engineering researchers. “PSS theory is still not mature, and most companies that consider migrating to this system change their minds,” says Rozenfeld. The researcher heads a team at EESC-USP that is working on a project aimed at designing a methodology to transform product-selling companies into product-service providers, with expected completion in 2018.

This servitization methodology, says Rozenfeld, is composed of multiple stages, including business analysis; setting out the value proposition–the product’s unique characteristics and how it will be perceived by the client; preparing the business model; creating the business case (a document that explains the business rationale to investors and banks, among other stakeholders); designing the information technology architectures, and the processes and services; and preparing and launching the value chain, which breaks down the company’s activities when it offers an integrated product-service solution. Right now, the team at EESC-USP is providing support for two companies that are interested in the system: a manufacturer of drones for agricultural irrigation and a maker of medical diagnostics equipment.

This servitization methodology, says Rozenfeld, is composed of multiple stages, including business analysis; setting out the value proposition–the product’s unique characteristics and how it will be perceived by the client; preparing the business model; creating the business case (a document that explains the business rationale to investors and banks, among other stakeholders); designing the information technology architectures, and the processes and services; and preparing and launching the value chain, which breaks down the company’s activities when it offers an integrated product-service solution. Right now, the team at EESC-USP is providing support for two companies that are interested in the system: a manufacturer of drones for agricultural irrigation and a maker of medical diagnostics equipment.

According to Mendes, who is participating in this project and in others with the same theme, the focus of current research is to understand the adoption of PSS practices by small and medium manufacturers of industrial machinery and equipment and to propose a set of guidelines, methods and tools to support smaller companies. “In Brazil, studies on PSS in small and medium businesses have received little emphasis, but in countries like France and Italy, servitization is already a reality,” he says.

The potential of the internet of things (IoT) for PSS solutions is being investigated by Zancul at USP. Production engineer Silvia Mayumi Takey, his former student, is developing this type of solution. She is a partner in DEV Tecnologia and coordinator of a FAPESP Innovative Research in Small Businesses Program (PIPE) project aimed at developing an IoT solution that can help Rochmam, a supplier of equipment for chemical solvent recycling, to migrate from its current business model–selling or leasing its machines–to PSS.

Rochmam and DEV are both incubated at the Center for Innovation, Entrepreneurship and Technology (Cietec) in the USP main campus. At an initial, already completed stage, DEV dedicated itself to developing the hardware and software needed for Rochmam to remotely monitor the operating parameters of its machines. The second stage of the project, now underway, is the development of a gateway–the connectivity equipment–that can be integrated with programmable logical controllers and that can be mass-produced at viable prices. The idea is for the IoT solution to provide the means for Rochmam to add services to its equipment and charge by solvent recycled.

Projects

1. Transformation methodology from product oriented offer to product-service system (PSS) (No. 15/23094-6); Grant Mechanism Regular Research Award; Principal Investigator Henrique Rozenfeld (USP); Investment R$47,206.47.

2. Reference model for managing the product-service system development process (No. 13/14549-4); Grant Mechanism Regular Research Award; Principal Investigator Glauco Henrique de Sousa Mendes (UFSCar); Investment R$28,144.08.

3. Application of internet of things technology to enable Product Service Systems (PSS) (No. 16/50062-0); Grant Mechanism Innovative Research in Small Businesses Program (PIPE); Principal Investigator Silvia Mayumi Takey (DEV Tecnologia); Investment R$952,355.59.