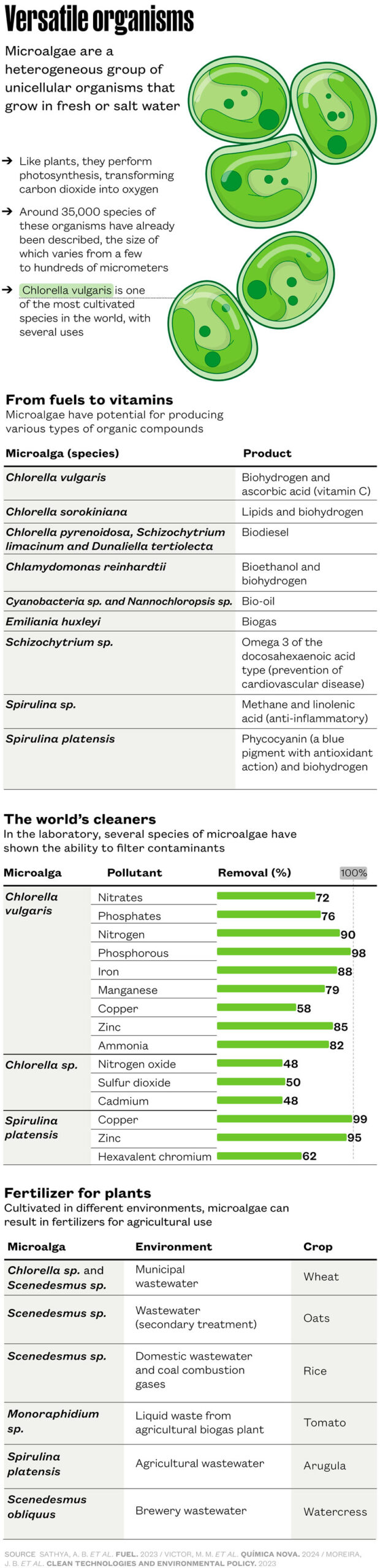

Two research groups, one in Curitiba in the state of Paraná, and another in São Carlos in the state of São Paulo, have developed new techniques for producing biofuels from microalgae. These unicellular aquatic organisms, which are among the oldest on the planet, reproduce quickly and are considered as production plants of biomass and bioactive compounds. Besides performing photosynthesis like plants, using sunlight and carbon dioxide (CO₂) from the atmosphere, they can use organic carbon sources present in waste. As a result, as long as they are in suitable light and temperature conditions, they produce oxygen and organic matter from which, through various separation processes, chemical compounds can be extracted and used as fuels, cosmetics, or dietary supplements. In the laboratory and in pilot plants, the microorganisms have shown to be capable of feeding on waste—from oil and ethanol production or even from farming animals, such as pigs, among others—and converting it into useful and environmentally acceptable chemical compounds. In all cases, there is still a great difficulty in increasing the scale of production.

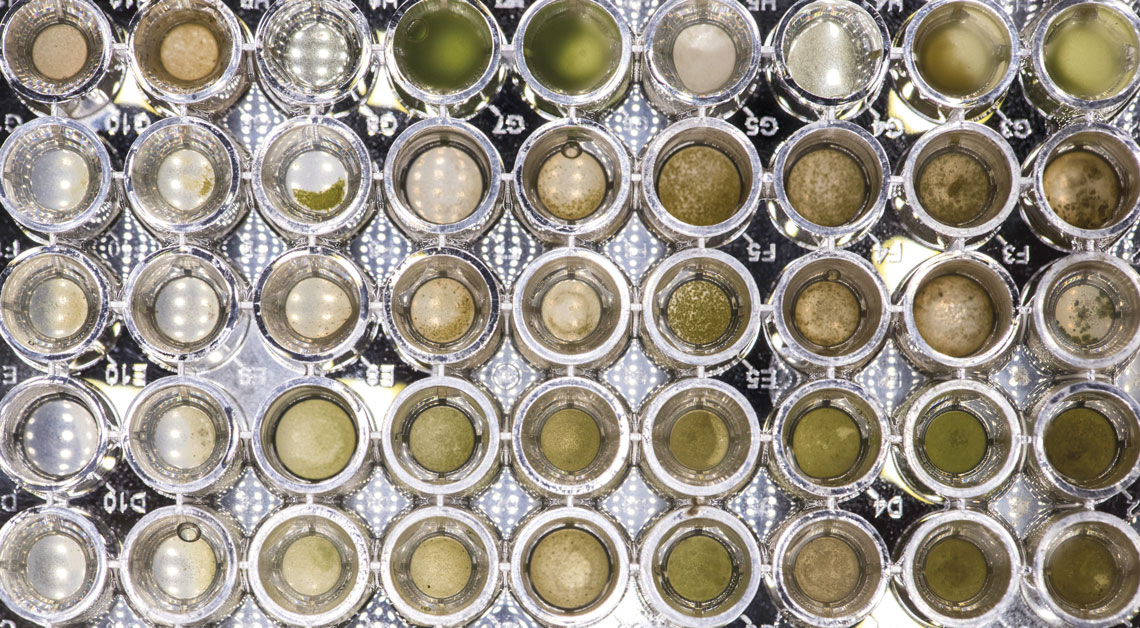

The Research and Development Center for Self-Sustaining Energy of the Federal University of Paraná (NPDEAS-UFPR) has carried out experiments attempting to address this issue. The group’s long-term aim is to produce green diesel, a biofuel with a similar composition to that of petroleum diesel. One of the studies uses photobioreactors on an industrial scale, with a capacity for 12,000 liters. The initial step is producing biomass from the microalgae in these devices. Once collected, the material is dried and dissolved in a hot solvent made from a mixture of chemical compounds. In the next step, the researchers remove the solvent and separate the resulting oils through distillation.

Initial results suggested that the conversion rate of the Tetradesmus obliquus microalgae concentrate into crude oil could reach 25%, a considerable increase compared to the current 10%. “It’s going well,” assesses petroleum and chemical engineer Iago Gomes Costa, responsible for the study. “We are in the phase of adjusting the temperature ranges, but we have already managed to recover the solvent from the concentrate, which could be reused, and separate the oil fractions.”

As described in an article published in September in the Journal of Environmental Management, through the distillation of crude algae oil, the researchers obtained 25 different compounds, including hydrocarbons such as alkanes, used in cooking gas and gasoline, and alkenes, a raw material for plastic packaging. The study by UFPR is one of the few in Brazil that goes beyond the stage of biomass production from microalgae.

Another possibility for producing biofuels with microalgae is being assessed in the laboratory of biologist Ana Teresa Lombardi, of the Federal University of São Carlos (UFSCar). At the beginning of September, in one of the rooms of the laboratory, the first test took place on a slightly larger scale, in a tank with a capacity for 20 liters. The objective was to increase, by maybe 70%, as already verified in smaller-scale tests, the yield from microalgae oil through a process patented by the team.

“We managed to get great results stimulating the microalgae with specific nutrients, so that growth is maintained and biomass with a high oil content is produced,” says Lombardi. “The traditional approach subjects them to stress, which interrupts growth.” The researcher from UFSCar plans to use her results for industrial applications.

Working independently, the teams from UFPR and UFSCar are renewing scientific and technical interest in microalgae. Around 15 years ago, they were seen as an alternative for reducing excess CO₂ in the atmosphere, converting it into biofuels that could be used in cars, planes, and ships, emitting less pollutants than fossil fuels.

However, microalgae did not produce the expected results. It was also found that commercial-scale production would not be viable and the final price would be more than double that of petroleum derivatives. As a result, many companies that had invested in the production of biofuels from this microorganism either closed or shifted the focus of their research. “The major difficulty is going from a laboratory production scale of 100 to 1000 liters to industrial scale of 10,000 liters and more,” comments agricultural engineer Sergio Goldemberg. In the laboratory, teams from research centers and companies have identified the optimal temperature ranges and nutrient combinations for the microalgae to form biomass from which commercially valuable compounds can be extracted. However, as production increased to volumes 10 or 20 times larger, it became more difficult to maintain a stable temperature, because biodigestion generates heat. As a result, the risk of bacterial contamination increased and the yield fell, making the process unfeasible.

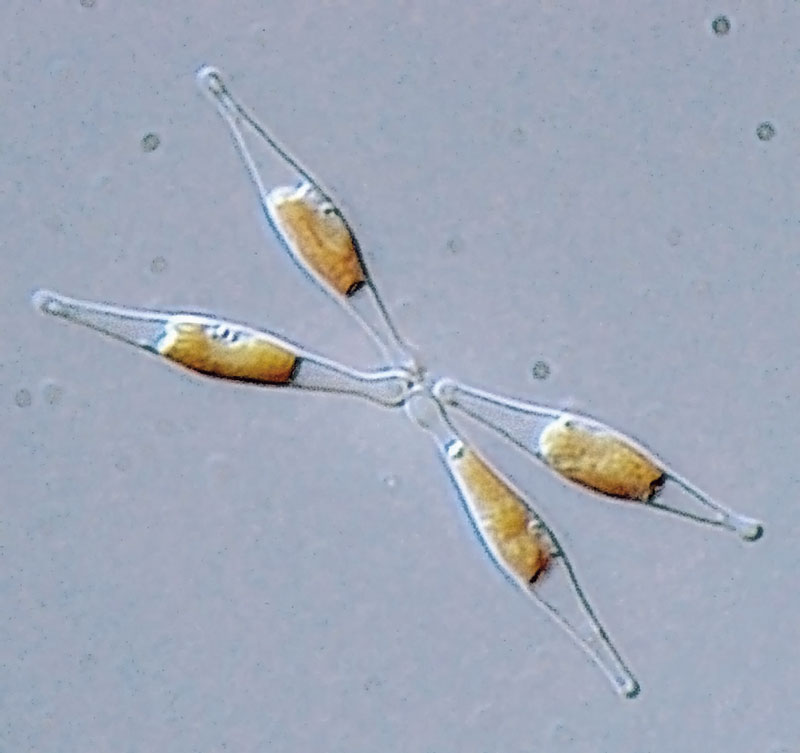

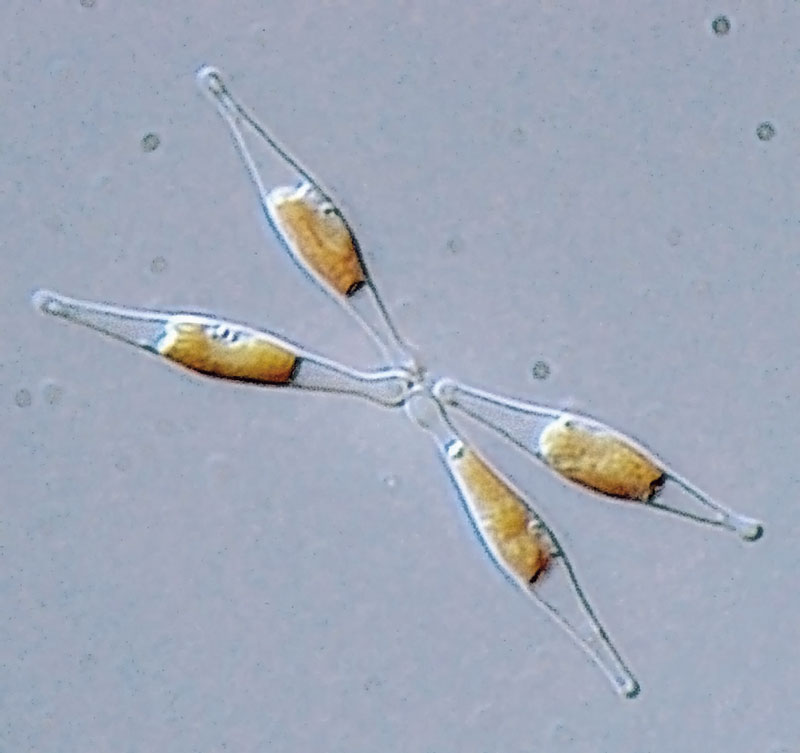

Alessandra de Martino / Chris Bowler / Stazione Zoologica / École Normale Supérieure / Wikimedia CommonsThe microalga Phaeodactylum tricornutum was capable of removing metals from an aqueous solutionAlessandra de Martino / Chris Bowler / Stazione Zoologica / École Normale Supérieure / Wikimedia Commons

In 2009, Goldemberg founded Algae Biotecnologia, one of the few Brazilian companies in this field. For years, the company survived with support from research funding agencies, including FAPESP. In 2014, a project began at InterCement, of the Camargo Corrêa group, aimed at using microalgae to utilize the CO₂ produced during cement production. After a few years, the contract to continue the research was not renewed and, in September this year, InterCement went into judicial recovery.

A foliar fertilizer to supply micronutrients and biostimulants to plants, developed by two companies using the microorganisms, showed good results in the laboratory, according to Goldemberg. But the difficulty in securing funding for field testing led to the work being halted. “We use vinasse [waste from the production of sugar and alcohol] to make the microalgae grow, but we had many technical difficulties,” he explains. In 2019, with no customers, Goldemberg closed the company.

Biologist Sílvia Helena Govoni Brondi experienced a similar situation. In 2020, with funding from FAPESP, she had obtained an orange pigment, carotenoids, important for human health, from microalgae such as Chlorella vulgaris, but was unable to prevent temperature fluctuations during the process, which hindered production. “The equipment is very expensive,” she says. Without additional funding, she also closed her company Algae Tech Pesquisa, in São Carlos.

Companies dedicated to market niches continue to operate, using microalgae to produce ingredients for cosmetics and food, such as pigments that give farmed salmon its pink color. In Brazil, Fazenda Tamanduá in Santa Teresinha (Paraíba) and Ocean Drop in Balneário Camboriú (Santa Catarina) produce spirulina (Arthrospira platensis). A microalga that is relatively simple to process, it can be used as a dietary supplement as it is a rich source of proteins, minerals, B-complex vitamins, iron, and antioxidants. In Orindiúva (São Paulo), Terravia, a subsidiary of a multinational company based in the USA, uses microalgae that consume sucrose from sugarcane to produce fatty acids, a type of oil used as an ingredient in soaps and face creams.

Possibilities have also emerged for using microalgae to reutilize industrial and agroindustrial waste and effluents. During a postdoctoral fellowship at UFSCar, fisheries engineer Lucas Guimarães Cardoso, in partnership with Lombardi’s team, developed a process using microalgae to treat what is known as produced water. The liquid, full of minerals, oil, chemical products, and gases, is used to make the oil from wells rise to the surface.

NPDEAS-UFPRPhotobioreactor at UFPR used for the cultivation of microalgae and biomass productionNPDEAS-UFPR

In 1.5-liter bioreactors containing cultures of Chlorella vulgaris, the group verified that the microalgae consume (feed on) the compounds present in the produced water. Based on this experience, two groups of commercially valuable products were generated: linoleic and palmitoleic acid, which are part of the composition of biodiesel, and carbohydrates and proteins, which can be used to produce ethanol. The researchers also managed to remove heavy metals such as copper, manganese, and molybdenum from the produced water, as described in an article published in 2022 in Environmental Technology & Innovation.

Since that year, as a professor at the University of Salvador (UNIFACS) in Bahia and the Graduate Program in Chemical Engineering of the Federal University of Bahia (UFBA), Cardoso has continued the research. At an international biotechnology congress held in August in Florianópolis, he presented a discovery of chemical engineer Ingrid Rocha Teixeira, his PhD advisor: fed with a solution of 50% produced water and 50% crude glycerol, the microalga Phaeodactylum tricornutum removed heavy metals more efficiently and produced a biodegradable polymer that could be a substitute for conventional plastics. “I intend to present the results in November to the companies that supply us the waste from oil exploration,” he says.

In another experiment, Cardoso and a group led by food engineer Jorge Alberto Vieira Costa, of the Federal University of Rio Grande (FURG), in Rio Grande do Sul, found that two species of microalgae, Spirulina sp. and Chlorella fusca, cultivated in brackish water, produced lipids and carbohydrates, respectively, as reported in an article from 2022 in Bioresource Technology. With colleagues from the Semiarid unit of the Brazilian Agricultural Research Corporation (EMBRAPA) and funding from the Ministry of Science, Technology, and Innovation (MCTI), Costa is preparing a pilot unit to be built in Petrolina (Pernambuco) in order to use the microalgae to produce foods, animal feed, fertilizer, and drinking water from brackish water, which is common in the sertão (badlands) of the Northeast of Brazil.

Another strategy to absorb contaminants from polluted water is a porous coal obtained through mild heating of a mass of microalgae. The method was developed by the group from FURG and described in an article in Enzyme and Microbial Technology, in 2023. Costa, coordinator of the group, who has worked in this field for 30 years, is optimistic: “The legislative pressure for the utilization of waste is increasing in Brazil.”

Microalgae also appear to thrive on waste, such as pig and poultry manure, which the NPDEAS team from UFPR diluted and used as a nutrient for these microscopic organisms. “They grow extremely quickly, in three days, instead of 15,” says industrial pharmacist André Bellin Mariano, vice coordinator of the group, of which postdoctoral fellow Ihana de Aguiar Severo is also a member. The research is on a pilot scale, with a 6,000-liter biodigester. The microalgae remove 99% of the phosphorus and nitrogen from the waste and produce water that could be used to quench the thirst of farm animals. “Despite good results, we still have some rough edges to smooth out in a number of waste utilization processes using microalgae,” Mariano comments.

The story above was published with the title “The multiple uses of microalgae” in issue 345 of November/2024.

Projects

1. Bioprospecting, characterization, and optimization of Brazilian microalgae for CO2 biofixation and production of commercially important biomolecules (n° 18/07988-5); Grant Mechanism Thematic Project; Principal Investigator Ana Teresa Lombardi (UFSCar); Investment R$3,011,694.89.

2. Defining the best cultivation systems for scaling production of new microalgae species (species selected in the previous stages of the Thematic Project) (n° 20/15688-1); Grant Mechanism Postdoctorate; Supervisor Ana Teresa Lombardi (UFSCar); Beneficiary Lucas Guimarães Cardoso; Investment R$153,834.88.

3. Cultivation of the microalgae Chlorella sorokiniana and Chlorella vulgaris for production of carotenoids and proteins to serve the pharmaceutical, food, cosmetics, and fine chemical industries (n° 17/50360-4); Grant Mechanism Innovative Research in Small Businesses (PIPE); Principal Investigator Silvia Helena Govoni Brondi; Investment R$431,085.08.

Scientific articles

BEZERRA, P. Q. M. et al. Innovative application of brackish groundwater without the addition of nutrients in the cultivation of Spirulina and Chlorella for carbohydrate and lipid production. Bioresource Technology. Vol. 345, 126543. Feb. 2022.

COSTA, I. G. et al. Unlocking pilot-scale green diesel production from microalgae. Journal of Environmental Management. Vol. 368, 122141. Sept. 2024.

COSTA, J. A. V. et al. Biochar production from microalgae: A new sustainable approach to wastewater treatment based on a circular economy. Enzyme and Microbial Technology. Vol. 169, p. 110281. 2023.

SILVA, D. A. et al. Strategy for the cultivation of Chlorella vulgaris with high biomass production and biofuel potential in wastewater from the oil industry. Environmental Technology & Innovation. Vol. 25, 102204. Feb. 2022.

VICTOR, M. M. et al. Microalgas: Uma estratégia sustentável na transformação e obtenção de compostos orgânicos. Química Nova. Vol. 47, no. 2, e-20230107. 2024.

MOREIRA, J. B. et al. Role of microalgae in circular bioeconomy: From waste treatment to biofuel production. Clean Technologies and Environmental Policy (2023). Vol. 25, pp. 427–37. 2023.

SATHYA, A. B. et al. Microalgal biofuel production: Potential challenges and prospective research. Fuel. Vol. 332, p. 2, 126199. Jan. 15, 2023.

Republish