MIGUEL BOYAYANA symbol of pollution: huge PET bottles on the banks of the Tietê River in São Paulo, in the art of Eduardo SrurMIGUEL BOYAYAN

A picture of waste in Brazil is being revealed by an analysis of the garbage produced in Indaiatuba, a city of 175,000 inhabitants in the Campinas region. The survey was carried out by researchers from the Paulista State University (Unesp) in Sorocaba, in the State of São Paulo, and reveals that almost 90% of the waste could be used and recycled and only 10% of the 135 tons of waste produced on a daily basis, such as disposable diapers, bathroom waste, batteries and other material capable of causing contamination, actually needs to be sent to the sanitary landfill site. The study that was published in December 2007 in Waste Management & Research, the official journal of the International Solid Waste Association, is part of a project for developing alternative processes for recycling plastic packaging made from poly (ethylene terephthalate), known as PET and used in soda, water and cooking oil bottles. The study is coordinated by Professor Sandro Mancini, from Unesp’s Environmental Engineering Department in Sorocaba, with funding from FAPESP.

The three plastic recycling processes studied by Mancini’s group produced encouraging results. One of them suggests an innovative way for obtaining terephthalic acid, one of the imported reagents used in the production of PET, from used and discarded plastic bottles, a cheap and abundant raw material. Data from the Brazilian Association of Chemical Industries shows that in 2007 Brazil imported 347,057 tons of this particular acid, worth US$ 337.8 million. This solution, which was the subject of Mancini’s PhD thesis at the Federal University of São Carlos (UFSCar), where his tutor was Professor Maria Zanin, is a type of chemical recycling process combined with the mechanical recycling of PET that consists of grinding, washing, drying and reprocessing and resulted in a patent being lodged. Caustic soda was added during the washing process with water. In chemical recycling the objective is to force the plastic to react in a way that is contrary to the reaction that occurred when it was being formed. “Instead of oil derivatives being polymerized to make plastic we use depolymerizarion reactions to obtain oil derivatives, like terephthalic acid”, explains the researcher. “It’s a new way of obtaining oil derivatives.”

With this new solution it is possible to achieve cleaner material that is suitable for the traditional mechanical recycling processes of discarded plastic bottles in which the resulting material is used to make, rope, brushes, carpets and other products. The combination of water and caustic soda causes the surface of the PET, where most of the impurities present in the recycled material are retained, to flake off. “The results were very good, indicating that removal of 5% of the material is enough to uncover a very much cleaner surface” reports Mancini. In order to reach this conclusion various trials were carried out, such as elementary analysis, viscosity, electronic microscopy and gas chromatography. The most obvious results came from electronic microscopy, in which it was possible to observe the reagent attacking and the surface being removed. “When we used the X-ray resource of microscopy we could analyze the composition of the minute surface pieces and we saw how very efficient chemical washing was for removing impurities that, because there was no selective collection, had become impregnated in the material through association with metals like aluminum, iron, potassium, calcium and sodium.” The process worked both for soda bottles as well as for used and discarded vegetable oil bottles.

However, a study of the organic compounds identified in oil packaging containers before and after being chemically washed indicated the need for a different type of recycling for obtaining products with the same quality as those deriving from soft drink containers. “Chemical washing was good, but not perfect, mainly in the case of vegetable oil packaging”, says Mancini. Even after this procedure they found 19 organic compounds from the 30 initially identified in this type of packaging. The material removed in the washing process is depolymerized PET from which terephthalic acid can be obtained by chemical and physical processes, such as dissolving, acidification and filtration.

Pure acid

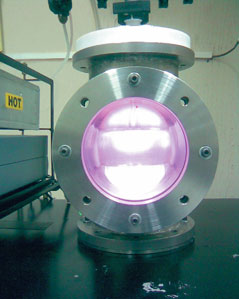

The second of the three processes studied also deals with the depolymerization of PET using chemical recycling to obtain terephthalic acid and ethylene glycol, another product derived from oil. In this case, with support from professors Elidiane Rangel and Nilson Cruz, also from Unesp Sorocaba, a treatment was used involving plasma from the air to leave the surface of the plastic bottles more receptive to the water used in the process. To form the plasma an electrical current was applied with low-pressurized gas. “Plasma helped increase the speed of the hydrolysis reaction”, says Mancini. With this process the researchers managed to obtain terephthalic acid in sufficient quantity and with a high degree of purity, but the study on ethylene glycol is still not finalized. The degree of purity of the product obtained is lower than expected by the research group. “Our intention is to obtain the two derivatives in a state that is as pure as derivatives coming from oil, to the point that they can be repolymerized to obtain new PET that can even come into direct contact with food”, says Mancini. In order for recycled packaging to be used in this way authorization is needed from the Brazilian Health Inspection Regulatory Agency (see text alongside). Even without publicity the process for obtaining the two oil derivatives using plasma has attracted the attention of a company from Paraná, but there is no contract for passing on this technology yet.

The mechanical recycling of PVC (polyvinyl chlorate) by applying sulfur hexafluoride plasma, a type of gas, is the third process studied by the group. The treatment was used to make the sample have less affinity with water in order to increase its surface resistance to an electrical current. In this way plasma-treated material conducts less electricity than material without treatment, which is good for common applications of recycled PVC, such as conduit. “In a comparison between the surface properties of recycled PVC and the pure product, we saw that the two materials were not a lot different”, says Mancini. The PVC used in this study was taken from a building waste landfill site in Sorocaba, because there is not much material of this type in household waste. The estimates, carried out with the support of the city administration, indicate that Sorocaba discards around 500 tons of building rubble and waste a day, in addition to a further 350 tons of domestic waste. This project has the technical support of Braskem.

Sandro Mancini/UnespPlasma chamber: gas to facilitate bottle washingSandro Mancini/Unesp

Another fact the group learned is that more aluminum and colorless PET is discarded in months when the weather is hot. Almost 26% in weight of the colorless PET discarded is packaging for oil, the price of which is lower than packaging for water and soft drinks because normally it contains more impurities, as seen in the study on chemical washing. The most frequently found waste plastic is high density polyethylene, which is used in supermarket bags, for example. The estimates believe that on average 5 kg of this material is discarded every day. To prove in practice that recycling is only worth doing when dry and wet garbage has been previously separated the researchers took samples of plastic bags from the sanitary landfill site to be recycled. The samples were weighed, washed, rinsed off, left to dry and weighed again, without their impurities. “In the ordinary collection the difference in weight was as much as 40%, while in selective collection it didn’t reach 10%”, says Mancini. This means that for every 1000 kilos of material for recycling after a conventional collection system only 600 kilos correspond to the plastic, the rest is dirt which will be transferred to the water after washing.

Rules for food

Recycled PET packaging was approved in April this year for use in wrapping food. The main demand when it comes to using PET for this purpose is that the product is registered with the Brazilian Health Inspection Regulatory Agency (Anvisa). Furthermore, the packaging label must carry the name of the producer, the batch number and the letters PET-PCR, for recycled post-consumption. The agency norm was based on the appearance of new technology that is capable of cleaning and decontaminating this type of material, regardless of the collection system used. Freeing up this material for use meets a demand of the Common Market of the South (Mercosur) that was agreed between member countries in December of last year. The decision is likely to contribute to the rate of recycling of plastic bottles that are discarded after use. In 2006, according to data from the Brazilian Association of the PET Industry (Abipet) published at the end of last year, of the 378,000 tons of PET manufactured in Brazil 194,000 tons were recycled, for the production of thread, rope and carpets, for example. The other 184,000 tons helped swell the size of waste dumps or ended up in streams, rivers or other unsuitable locations.

Details of municipal waste

The analysis of waste from Indaiatuba also gives some clues as to the consumption patterns of Brazilian families. “A social-economic analysis of waste indicated that lower class neighborhoods discard less packaging and more food, shoes and rubble”, says Mancini. Ten samples were obtained directly from the garbage collection truck between September 2004 and July 2005. The choice of each sample took into account the geographic region of the city, the season of the year when the collection was made and the social class of the neighborhood. According to data from the Brazilian Institute of Geography and Statistics (IBGE), 2001, the upper class represents 11% of the population, while the middle and lower classes represent 55% and 34%, respectively. The waste was subdivided into 27 items, each one chosen for its potential, or otherwise, for recycling. The separated items were leftover food, diapers, bathroom waste, cloth material, footwear, batteries, milk carton packaging, glass, steel cans, aluminum, building rubble, paper and plastic. Of these items 23 can be reused and recycled, provided the management of solid waste is associated with selective collection. Of the 135,000 kg of waste discarded every day 54,000 kg, corresponding to 40% of the total, is leftover food. When added to the leaves and branches of trees, which are included in the garden waste category, this adds up to 55% organic material rotting in the sanitary landfill site. Calculations indicate that the average cost of collection and disposal of waste is around R$ 100 a ton. In smaller cities, because of the shorter transport distances this figure falls to R$ 70 a ton. “In Indaiatuba alone, almost R$ 10,000 a day is spent collecting and burying waste, which means R$ 3 million a year, added to another R$ 6 million annually in materials that might be recycled”, says Mancini. Although the data are from Indaiatuba, they can be extended to other municipalities that do not have selective collection programs.

The project

The development of alternative processes for recycling poly (ethylene terephthalate) coming from solid urban waste (nº 04/08718-9); Modality Support Program for young researchers; Coordinator

Sandro Donnini Mancini – Unesp; Investment R$ 79,015.94 (FAPESP)