Léo Ramos Chaves / Pesquisa Fapesp Bottle of sustainable aviation fuel produced at the National Biorenewables Laboratory in CampinasLéo Ramos Chaves / Pesquisa Fapesp

It is not only the productive sector that is taking an interest in sustainable aviation fuel (SAF). The topic is also attracting interest from academia. One major initiative in the area was last year’s inauguration of the “SAF Hub” at E-Renova, a division of the Brazilian Agency for Industrial Research and Innovation (EMBRAPII) that is based at the University of Campinas (UNICAMP) and focuses on innovation in renewable energy.

“The idea is to connect all of the stakeholders involved in the production and use of SAFs, including companies that own the technology, universities that study technological methods, airlines, ANAC [Brazil’s National Civil Aviation Agency], and the ANP [Brazilian Agency for Oil, Natural Gas, and Biofuels],” says Rubens Maciel Filho, head of E-Renova and a professor at UNICAMP’s School of Chemical Engineering (FEQ).

Maciel claims that Brazil is the country with the greatest manufacturing capacity for alternative fuels. “We must produce it here so we don’t end up exporting ethanol and then importing aviation biofuel,” says the researcher, who is also a member of the team that manages FAPESP’s Bioenergy Research Program (BIOEN).

The National Biorenewables Laboratory (LNBR), part of the Brazilian Center for Research in Energy and Materials (CNPEM), is another Brazilian institution that is investigating SAF, among other lines of research. It conducts studies on two fronts, both with funding from FAPESP. On one front, researchers evaluate the sustainability impacts of more advanced methods—for example, observing a certain biomass’s potential to meet a regional or global SAF demand, considering the effects of land use changes, and prioritizing areas with low emissions risks.

On the other, they seek to develop new 100%-Brazilian technologies. In an article published in Proceedings of the National Academy of Sciences in 2023, LNBR physicist Leticia Zanphorlin and her colleagues described an enzyme capable of replacing traditional chemical catalysts in thermochemical pathways used to transform fatty acids into hydrocarbons.

“It is an interesting enzyme because not only can it carry out this conversion, but it is also capable of deoxygenating the molecule,” explains chemical engineer Edvaldo Morais, head of LNBR’s Biorefineries and Natural Resources Division. “In a conventional process, an additional step is required in the reaction, using hydrogen to remove oxygen from the biomass molecules.” Two other articles about studies carried out at CNPEM were published last year in the Chemical Engineering Journal and Resources, Conservation and Recycling.

In another project funded by FAPESP, researchers at UNICAMP are using computer simulations to study the economic viability of ATJ biorefineries using two inputs: second-generation ethanol from energy cane (a variety that contains more fiber and is more resistant to pests) and sustainable hydrogen generated from urban waste, known as refuse-derived fuel (RDF). “The idea is good from a sustainability perspective, but we still need to determine whether it is economically viable,” says FEQ-UNICAMP chemical engineer Adriano Mariano, who is leading the study.

The role of hydrogen

Hydrogen is a vital input for SAF production. By reacting with carbon dioxide (CO2), it generates long-chain hydrocarbons similar to those in aviation kerosene. The Center for Research and Innovation in Greenhouse Gases (RCGI), an Engineering Research Center (CPE) created with funding from FAPESP and Shell, and the Bioenergy Research Group (GBio) at the Institute of Energy and the Environment (IEE) of the University of São Paulo (USP) are studying the potential for hydrogen production via different methods by the sugar and ethanol sector. Researchers will analyze data from almost 400 ethanol plants across Brazil.

“Green hydrogen is essential to all SAF production methods,” says international relations analyst Laís Forti Thomaz, who is a professor at the Federal University of Goiás (UFG) and a member of the National Council for Energy Policy (CNPE), an advisory board to the Brazilian president.

“The two methods with the most potential due to the abundance of raw materials are ATJ, which uses ethanol, and HEFA, which uses soy, used cooking oil, or beef fat. We already have a really strong biodiesel chain that can help in the production of raw materials,” points out Thomaz, highlighting that it is best not to focus on just one approach. “The ideal strategy is to promote the development of all methods.”

1. What is SAF made from?

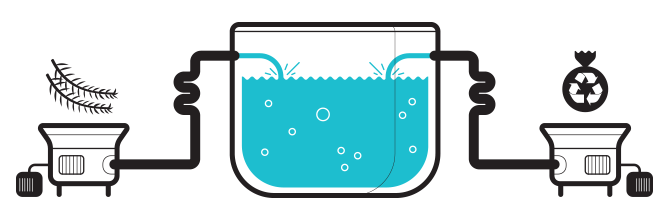

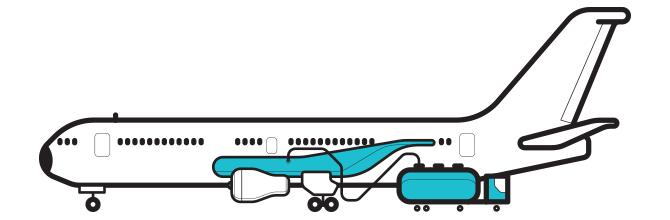

It is produced from agricultural and forestry residue, oilseeds, urban solid waste, and used cooking oil, among other inputs. It can be synthesized by capturing carbon dioxide (CO2) from the atmosphere. Mixed with petroleum-derived or pure kerosene, its use requires no modifications to current aircraft or fueling infrastructure.

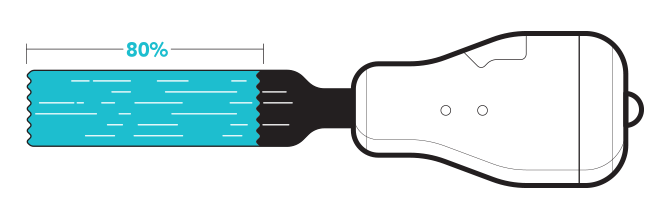

2. What is the main advantage?

With the same chemical structure as aviation kerosene, SAF also releases CO2 when burned, but it emits less of the greenhouse gas (GHG). Depending on the technological method and raw material used, GHG emissions can be reduced by up to 80%.

3. What technological methods are used in its production?

Eight methods have been approved to date by the American Society for Testing and Materials and the ANP. The most common methods are:

– HEFA (Hydroprocessed Esters and Fatty Acids): the most advanced method, certified in 2011. The raw materials include vegetable oils (soy, palm, macauba, babassu, cotton, castor, sunflower, and others), used cooking oil, and animal fat, such as beef tallow. The production process requires a large volume of hydrogen.

– ATJ (Alcohol-to-Jet): certified in 2016, this method uses starches, sugars, cellulosic biomass, or ethanol derived from sugarcane or corn. It also consumes a high volume of hydrogen.

– FT (Fischer–Tropsch): certified in 2009, the Fischer–Tropsch process uses biomass from urban, agricultural, and forestry (sugarcane, eucalyptus, and others) residue. The raw material is gasified and transformed into carbon monoxide and hydrogen (synthesis gas), which is converted into biofuel.

Sources: Bill 4.586/2023; study “Economic analysis of different production methods for sustainable aviation fuels” (ProQR); Darlan Santos/ANAC; IATA

Projects

1. New P450 mechanisms:An enzymatic strategy for producing renewable hydrocarbons (nº 19/08855-1); Grant Mechanism Regular Research Grant; Principal Investigator Leticia Maria Zanphorlin (CNPEM); Investment R$168,949.39.

2. Enzymatic production of biodiesel and renewable hydrocarbons: From obtaining the enzyme to economic evaluation of the integrated process (nº 18/04897-9); Grant Mechanism Postdoctoral fellowship; Supervisor Antonio Maria Francisco Luiz Jose Bonomi (CNPEM); Beneficiary Letícia Leandro Rade; Investment R$560,516.67.

3. SYMBioref: Symbiotic energy cane biorefinery (nº 23/01072-7); Grant Mechanism Bioen Program; Principal Investigator Adriano Pinto Mariano (UNICAMP); Investment R$230,544.71.

4. Research Center for Innovation in Greenhouse Gases (RCGI) (nº 20/15230-5); Grant Mechanism Engineering Research Centers (CPEs); Principal Investigator Julio Romano Meneghini (USP); Investment R$17,261,689.15.

5. Project BioValue – Valorization of the decentralized biomass production chain for the production of advanced biofuels: Development and evaluation of thermochemical methods integrated into biomass production and biochemical methods (nº 16/50403-2); Grant Mechanism Research Partnership for Technological Innovation (PITE); Principal Investigator Antonio Maria Francisco Luiz Jose Bonomi (CIEMAT); Investment R$1,262,596.21.

Scientific articles

RADE, L. et al. Dimer-assisted mechanism of (un)saturated fatty acid decarboxylation for alkene production. PNAS. Vol. 120, no. 22. 2023.

CHAGAS, M. F. et al. From enzyme to cell-factory: Economic and environmental assessment of biobased pathways to unlock the potential of long-haul transportation biofuels. Chemical Engineering Journal. Vol. 469. 2023.

PETRIELLI, G. P. et al. Integrating carbon footprint to spatialized modeling: The mitigation potential of sugarcane ethanol production in the Brazilian Center-South. Resources, Conservation and Recycling. Vol. 189. 2023.