Sodium (Na), a chemical element abundant in nature is found in sea water and salt reserves on every continent. Experts estimate that this substance could be an important alternative in the energy storage process, with the potential to replace up to 25% of today’s lithium batteries, which are used to power electric cars, drones, smartphones, notebooks, tablets, and other electronic devices.

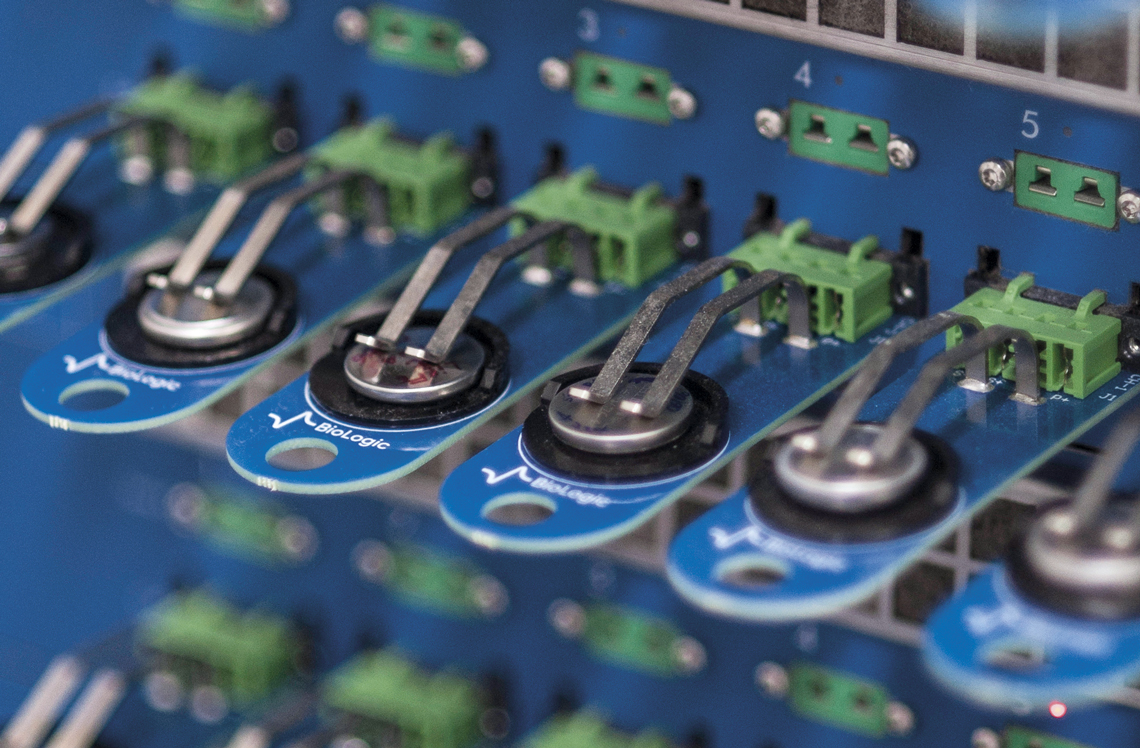

Currently, a team from the School of Electrical and Computer Engineering at the University of Campinas (FEEC-UNICAMP) is developing the first Brazilian sodium battery prototype. Currently, only Chinese manufacturers offer commercial batteries using this technology, and the first electric vehicles equipped with these modules are expected to be on the market this year.

The Brazilian project is being developed within the scope of the Center for Innovation in New Energies (CINE), an Engineering Research Center (CPE) supported by FAPESP, with the Anglo-Dutch company Shell. “We already have the capacity to develop the technology and produce the first prototypes,” says physicist Hudson Zanin, a professor at FEEC-UNICAMP and the project’s lead researcher.

Together with colleagues from the Santa Catarina company WEG, which specializes in manufacturing electric motors, UNICAMP researchers recently submitted a project proposal to the national program Rota 2030, which was created to stimulate innovation in the automotive production chain. The proposed goal is to develop and produce 1-amp-hour (Ah) sodium batteries with 1.2 kilowatt-hour (kWh) energy storage modules suitable for equipping hybrid electric cars. These types of vehicles are fueled with liquid fuel, such as gasoline and ethanol, and use a complementary electric motor powered by the combustion engine itself.

The sodium and lithium battery technologies are very similar, as Zanin explains. In both battery types, ions (atoms that have an electric charge) carry out the task of transporting and storing electrons during the energy charge and discharge processes. To do this, the ions must penetrate the structure of the electrodes, which are made up of a positive pole — the cathode — and a negative pole — the anode.

The difference is that the sodium ion is larger than the lithium ion and thus has more difficulty penetrating the structure of the electrodes. This makes developing electrodes that facilitate this operation a prerequisite. “In lithium batteries, the anode is made of graphite; in sodium batteries, it is made of a different carbon structure. One uses lithium-based cathodes and the other sodium,” explains Zanin.

In August 2022, the UNICAMP team published an article in the Journal of Energy Storage demonstrating the potential of using a new material for electrode construction, one composed of carbon nanotubes with nanoparticles of niobium pentoxide, which increased the capacity and speed of transport and storage of electrical charges from sodium ions. The study evaluated sodium electrodes used in batteries and in supercapacitors, which are electronic devices also used for energy storage.

The research was conducted as part of computer engineer Carla Martins Real’s doctorate in electrical engineering, under Zanin’s guidance, with participation from researchers from Kansas State University in the United States, the Federal University of Jequitinhonha and Mucuri Valleys (UFVJM) in Minas Gerais, and the Federal University of Mato Grosso (UFMT).

Lithium batteries are currently considered the most efficient technology for increasing energy density (see Pesquisa FAPESP issue nº 285). These batteries have a 30% greater energy-carrying capacity than a sodium battery with the same physical volume. In addition, they are more durable because they have better cyclability; that is, they perform a greater number of energy charge and discharge cycles. While a lithium battery can perform 12,000 cycles during its useful life, sodium batteries — for now — have not yet reached 4,000 cycles.

Zanin considers, however, that sodium modules have significant competitive advantages that could boost their use in the coming years. “Sodium is an affordable raw material available in any country. Refining it on a large scale will provide the sodium battery greater economic viability when compared to lithium batteries, which will face strong market demand,” he says.

Sodium batteries will occupy specific market niches, such as storage for wind and solar energy

Lithium is an ore with limited known reserves that is found only in a few countries, such as Bolivia, Chile, Argentina, Portugal, and Australia. In Brazil, the only known commercially viable reserve is in the Jequitinhonha Valley in Minas Gerais. According to a 2021 estimate by the International Energy Agency (IEA), lithium consumption is expected to increase 75-fold by 2050.

The global consultancy Benchmark Mineral Intelligence calculates that it will be necessary to open 59 new lithium mines just to meet the demand expected through 2035. “Since there won’t be enough lithium for everyone, sodium could be an alternative,” Zanin says.

Another problem with lithium, explains the researcher, is that the process of refining the ore to a grade adequate for use in batteries consumes a large amount of energy. When the energy sources used are not renewable, he points out, the production process has a large environmental impact. “Extracting and processing sodium, on the other hand, has a very low carbon footprint,” he observes.

Despite these advantages, chemist Roberto Manuel Torresi, an electroactive materials specialist from the Institute of Chemistry at the University of São Paulo (IQ-USP), believes that sodium batteries will not replace lithium storage modules but will occupy niches in different markets.

He says that lithium batteries, due to their energy density, tend to predominate in light electronics. Sodium technology will be applied in stationary batteries, such as those used in energy security systems for data centers and ATMs or for storing wind and solar photovoltaic energy to reduce interruptions in the power supply when there is a lack of wind and sun. “In other words, sodium batteries are interesting but destined for specific applications,” says Torresi.

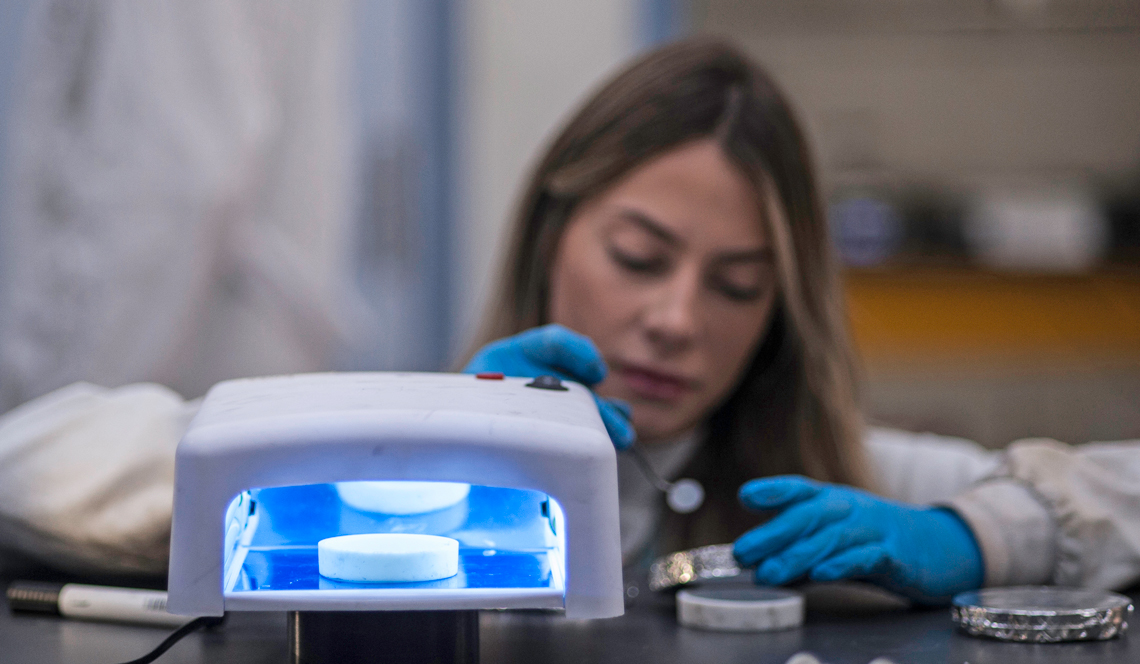

Léo Ramos Chaves / Revista Pesquisa FAPESPAnna Peluso, a master’s student at UNICAMP, works on a sodium battery assemblyLéo Ramos Chaves / Revista Pesquisa FAPESP

Electric vehicles

Zanin, however, also sees potential in the electric vehicle sector. He expects that at first, the technology will be used for large vehicles, such as buses, trucks, trains, and ships.

In China, recently, automakers announced that they were preparing to launch electric cars with sodium-ion batteries. BYD, which also makes batteries, will use its own technology, while the automaker Chery will use modules designed by the Chinese battery manufacturer CATL. Since February, an electric model from Jac Motors has been tested with a system created by the HiNa Battery.

French automaker Renault, which maintains a partnership with the Chinese corporation Jiangling Motors Electric Vehicle (JMEV), announced that it would launch its first vehicle using sodium batteries later this year, with technology supplied by the Chinese firm Farasis Energy. “The abundance of sodium supply in virtually all countries,” predicts that Zanin “will allow for the emergence of various energy storage technologies and different production processes around the world.”

For Flávia Consoni, the founder and coordinator of the Light Electric Vehicle Study Lab (LEVE), which is based at the Institute of Geosciences (IG) at UNICAMP, batteries remain the major bottleneck for the expansion of electric mobility due to the growing demand for natural resources and the environmental and social impacts of mining. Therefore, initiatives that investigate the use of other minerals, in addition to lithium, are always welcomed and necessary. “The sodium battery is already a reality for stationary applications. It has potential for other purposes, but these are still future prospects. Despite recent advances, the technology still has issues, such as the need to increase its energy density. These are aspects that need to be considered, especially when thinking about applications that demand high energy density.”

An additive developed in Brazil is designed to prevent batteries from catching fire

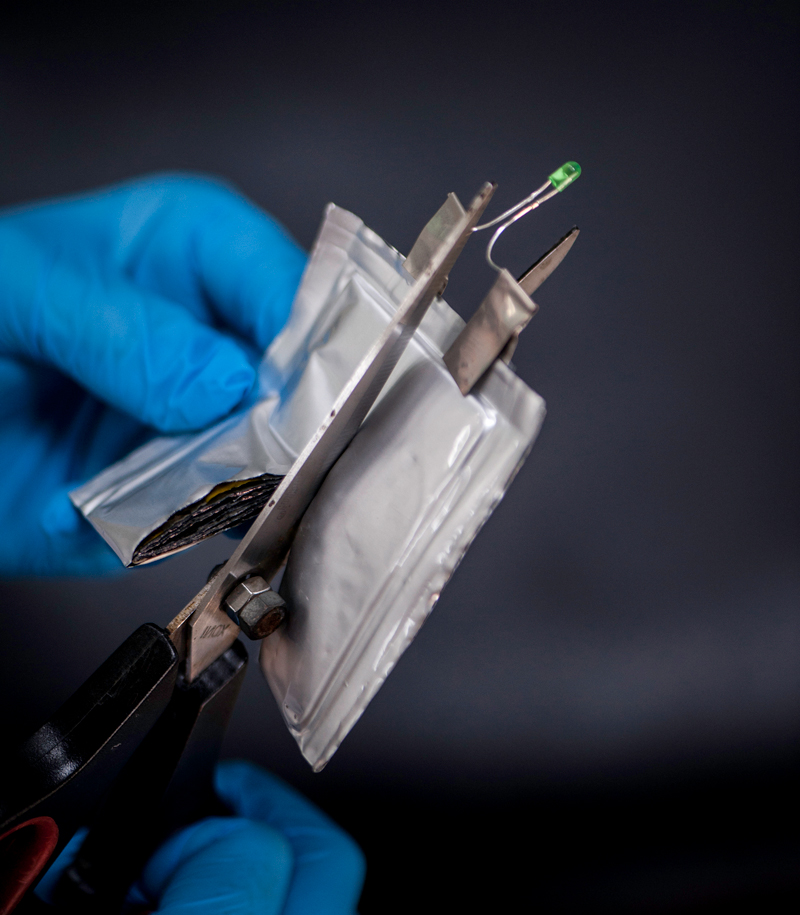

Léo Ramos Chaves / Revista Pesquisa FAPESPA battery prototype created by the Campinas research group is cut into, without catching fireLéo Ramos Chaves / Revista Pesquisa FAPESP

One undesirable characteristic of batteries is that they are flammable. Shocks, punctures, and overheating pose safety risks for smartphone users, notebooks, and electric vehicles. An additive capable of preventing these devices from catching fire was developed by researchers at CINE, a research center supported by FAPESP and Shell.

“The additive is a polymer that, when added to a battery’s electrolyte, prevents fires,” explains physicist Hudson Zanin from FEEC-UNICAMP. The recipe used for the polymer is being kept secret, as the technology is under patent analysis at the National Institute of Industrial Property (INPI).

An electrolyte is most commonly a liquid substance that is used for conducting electrical ions between the two poles (cathode and anode) of a battery. They are usually produced from fossil hydrocarbons obtained during the oil refining process and are flammable as a result.

“The innovation our group created uses conventional electrolytes to which an additive is added that plasticizes and unifies the electrolyte’s molecules, preventing a possible fire in the equipment,” explains Zanin. In tests carried out at UNICAMP, batteries treated with the additive were cut, perforated, and exposed to fire and did not burn or explode.

The additive, according to the researcher, will be a very small ingredient in the formulation of the electrolyte. Because the polymer used is inexpensive and accessible, the eventual application of this technology should not have a significant impact on the end cost of batteries or supercapacitors (electronic devices that are also used for energy storage).

The São Paulo startup Brenergies Solutions, a spin-off from FEEC-UNICAMP formed by professors and students from the institution, will be responsible for making the additive available to the market. There is still no set time frame for its release.

The global search for technologies to prevent batteries from burning saw its first product hit the market in 2021, with the launch of a less flammable lithium-iron-phosphate battery created by the Chinese electric vehicle manufacturer BYD. The new battery underwent extreme test conditions and was drilled, crushed, and heated in an oven at 300° C without fires or explosions. The module is already applied in certain BYD vehicle models.

Project

Cine – Division for advanced energy storage (nº 17/11958-1); Grant Mechanism Engineering Research Centers (CPEs); Principal Investigator Rubens Maciel Filho (UNICAMP); Investment R$8,646,512.62.

Scientific articles

REAL, C. G. et al.Freestanding niobium pentoxide-decorated multiwalled carbon nanotube electrode: Charge storage mechanism in sodium-ion pseudocapacitor and battery. Journal of Energy Storage. aug. 15, 2022.