IFGW/UnicampY Fiber – applications in biological and chemical sensingIFGW/Unicamp

Approximately 30 years ago, Brazil joined the then select group of countries that studied and used optical fibers, filaments made of glass or of polymeric material as thick as a strand of hair, able to transmit data in the form of light at a very high speed. One of the first optical fiber networks was installed at the State University of Campinas (Unicamp), in May 1977, for telecom tests, telecommunications being a field that had undergone a veritable revolution through the mass use of optical fibers instead of copper wire. Today, thirty years later, Unicamp is still at the forefront of research into this technology and is the seat of a laboratory focused on the research and development of photonic crystal fibers, considered the new generation of optical fibers; photonic crystal fibers have expanded the use of this material to the fields of biology and chemistry, for example; more specifically, to analyze gases and liquids. Last year, this lab’s researchers, in conjunction with researchers from other Brazilian and overseas institutions, filed three patents related to photonic crystal fibers, which will be discussed at the international workshop on Special Optical Fibers and their Applications, scheduled to take place in the city of São Pedro, State of São Paulo, in August this year (www.wsof2008.org). The event will bring together leading global experts in this kind of optical fiber, which was developed at the end of the 1990’s by Great Britain’s Philip Russell, from England’s University of Bath, one of the major research centers conducting research on this material.

The photonic crystal fibers are part of a bigger group referred to as special optical fibers, because they have structural innovations that distinguish them from other fibers. The main difference between traditional optical fibers and the photonic crystal ones is that the traditional ones have a regular arrangement of holes, the diameters of which measure one millionth of a meter, running parallel to the axis of the fiber and along the entire length. The advantage of these micro-holes is that they enable strict and substantial control of the light guide, which makes the fiber more versatile. This happens because the microstructure can be designed in different ways, in order to provide the requisite properties. Thus, it is possible to prepare fibers for a broad group of applications. In addition to telecom networks and equipment, the photonic crystal fibers, also known by their acronym PCF, can be used to manufacture laser devices, light sources or ultra-sensitive optical sensors capable of monitoring an environment containing hazardous gas or a liquid contaminated with bacteria, for example. “The photonic crystal fibers represent a wide-ranging innovation,” states physicist Cristiano Monteiro de Barros Cordeiro, a professor at the Gleb Wataghin Physics Institute (IFGW) at Unicamp. “Our leeway for working with the characteristics of the traditional optical fibers is very restricted, but when we insert holes in the structure, the freedom to choose the optical properties increases substantially,” says Cordeiro.

Guided wires

Even though this technology is relatively new, photonic crystal fibers are already available on the market. The pioneering company in this area is Denmark’s Crystal Fibre; since 2000, it has been selling different kinds of fibers and telecom equipment made from this material. At Unicamp, one of the main recently developed innovations is a photonic crystal fiber with electrodes (metal wires), developed by Giancarlos Chesini, a student in the master’s degree program. Thanks to this innovation, one can apply voltage to the fiber or pass an electric current through it while it is being guided. “The light can be modulated with the electric current, which opens up new perspectives for using this material in the sensory field and in terms of devices, as, for example, in the manufacturing of optical modulators used in data transmission networks,” Cordeiro explains. Cordeiro went to Center for Photonics and Photonic Materials at the University of Bath for his post-doctoral studies.

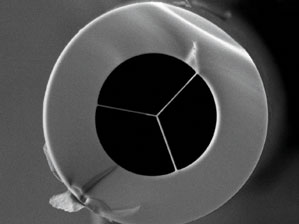

Another innovation produced by the group, which is part of the Center for Research on Optics and Photonics of Campinas (CePOF), also located at IFGW-Unicamp and financed by FAPESP, is a fiber that was baptized ‘Y’. Its structural uniqueness is its small core, only 1 micrometer in diameter – the core of traditional fibers measures some 10 micrometers and the total diameter measures 125 micrometers. In addition, the ‘Y’ fiber only has three holes in its microstructure; these holes are quite big relative to those of ordinary photonic crystal fibers. Reducing the core makes it more sensitive and appropriate for chemical or biological sensory applications. This happens because of the diffraction effect that extends the propagation of light beyond the core. “The diffraction phenomenon is terrible in data transmission in a telecoms network, but highly desirable in sensory matters. The holes in the fiber allow the light to enter into contact with the material that is to be identified and analyzed, such as a given liquid or gas,” explains the researcher from Unicamp.

edardo cesarMetal wire integrated into optical fiber allows the passage of an electric currentedardo cesar

The first patent filed last April by Inova, the Unicamp innovation agency, concerns the structure of photonic crystal fibers. “In addition to the holes around the core, we made other holes on the sides, perpendicular to the axis of the fiber to de-couple the entry of the light and the material. Thus, the light keeps entering through the end of the fiber, just as with any other fiber, while the material to be analyzed enters through the sides,” says physicist Christiano José Santiago de Matos, a professor at the Optical Communications and Photonics Laboratory of Mackenzie Presbyterian University, and co-author of the patent. To function as a sensor, light needs to come into contact with the analyzed material. The analysis takes place by means of the diffraction of part of the light that travels through the core to the fiber’s sheath, generating an evanescent field, in which the light tries to escape from the core. The openings in the holes on the side makes the analyzed material – whether it’s a liquid or a gas – enter through them and the material comes into contact with this evanescent field. The patent request related to this technology was filed last year with the INPI, Brazil’s the patent-granting agency.

A similar process with the same objective of accessing the inside of the fiber through the sides resulted in a second patent, an international one in this case, which was the result of a partnership between the group from Unicamp and the Optical Fiber Technology Center (OFTC) at the University of Sydney, in Australia, one of the most advanced centers of studies about special optical fibers. Instead of the holes on the side, the fiber had a split running along it, which was dozens of centimeters long. “This technology had a great impact not only because it was international, but also because it comes closest to the practical application in the field of chemistry sensoring; it can be used, for example, for monitoring chemical leaks in industries or even in oil wells,” says Cristiano Cordeiro. An article on this technology was published recently in Optics Express, the on-line journal of the Optical Society of America, considered to have a huge impact on the optical field.

The third patent, filed with the INPI in October 2007, again in partnership with Mackenzie University, concerns photonic crystal fiber with a core and a sheath (the part of the fiber that covers the core) filled with different liquids such as water, ethanol or methanol. “In this project, we used water in the sheath and a mixture of water and glycerin in the core. This kind of fiber will be used mainly in soundings and sensory measurements as, for example, to conduct the spectroscopic analysis of liquids, to measure the emission or absorption of the substance’s electromagnetic radiations. The liquid core of micro-structured fibers can provide strong interaction of the light with the analyzed material, thus facilitating the analysis. “But to keep the light wave from traveling at different speeds and pathways inside the liquid core, a phenomenon called modal dispersion, we used a second liquid in the fiber’s sheath, which controlled the direction of the first liquid,” says Christiano de Matos, from Mackenzie. Thus a single-mode fiber was created, which is one of the traditional fibers, and a market preference; traditional single-mode fibers allow the light to ‘travel’ at a regular pace, and thus provide a better signal. The development of this fiber made it necessary to overcome a series of obstacles, such as the need to fill such tiny spaces as the core and the sheath of an optical fiber without mixing the two liquids.

The fiber comprised of liquid core and sheath is expected to be shown at a workshop to be held in the city of São Pedro. The event is supported by international societies such as OSA and SPIE, as well as by FAPESP. Of the 30 guest speakers, 25 come from abroad; among them is British physicist Jonathan Knight, from the University of Bath, who took part in the development of the first photonic crystal fiber, and Australian researcher Maryanne Large, of the University of Sydney, responsible for the pioneering development of photonic crystal plastic fibers.

The Project

Photonic crystal fibers; Type Cepid – Center for Research, Innovation and Dissemination; Coordinators Hugo Fragnito – CePOF Center of Optics and Photonic Research at Unicamp and Cristiano Cordeiro – Subproject; Investment R$ 1,000,000.00 a year for all of CePOF (FAPESP)