EDUARDO CESARHybrid cells used for monoclonal antibody productionEDUARDO CESAR

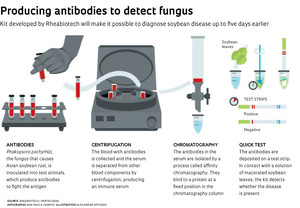

Two projects developed by Rheabiotech, a small biotechnology company in the city of Campinas, may help control diseases of two important crop plants in Brazil. The company’s laboratories are producing antibodies for use in kits for diagnosing Asian soybean rust (a fungal infection) and two types of viruses that afflict potatoes. Asian soybean rust is caused by the fungus Phakopsora pachyrhizi, which attacks the leaves of the soybean plant and causes the soybeans to wither, with consequent productivity loss for growers. A total of $25 billion were lost because of the disease between 2003 and 2013, according to the Brazilian Confederation of Agriculture and Livestock (CNA). Asian soybean rust is difficult to control and requires constant application of fungicides, as the fungus can only be visually detected with a magnifying lens at the early stages of the disease. “The problem is that the disease is only detected after the plantation is already infested, so one never knows exactly when to apply the fungicide,” explains biologist Luís Antônio Peroni, managing partner at Rheabiotech. “Because of this uncertainty, fungicides get applied up to six or seven times per growing period, increasing costs.” A kit currently being developed in partnership with ParteCurae Analysis, a company based in the city of São Carlos, will be able to diagnose the disease up to five days earlier, before contamination has spread.

The first step in manufacturing the kit is obtaining antibodies against P. pachyrhizi. This requires an antigen, in this case the fungus’ own mycelium, which is the filamentous part of its body. The antigen is inoculated into rabbits on four different occasions, at 15-day intervals, until the animals become immune. In other words, the rabbits produce antibodies to fight the antigen. “The rabbit blood with these antibodies is collected, and an immune serum is extracted from that blood,” explains Argentinean-born biochemist Fernanda Alvarez Rojas, managing partner at Rheabiotech. “The antibodies in the serum are then purified.”

The antibodies obtained through this process are called polyclonal antibodies because they are produced by different clones of B lymphocytes, a type of cell in the immune system. The end result is a mixture of immunoglobulin molecules produced against a specific antigen. Each molecule recognizes a distinct region – called an antigenic determinant or epitope – of that antigen. Many types of polyclonal antibodies are already available on the market, sold for diagnostic tests or to fight infectious diseases. But there is another type of antibody, called a monoclonal antibody, which is produced from a single B lymphocyte and can recognize and fight one specific region of an antigen. In other words, monoclonal antibodies are more specific and therefore provide a major advance in the treatment of many diseases, especially cancer. The production process for monoclonal antibodies differs from the one described above.

Eduardo CesarOven where antibodies are producedEduardo Cesar

The first step is to immunize mice with the target antigen, then collect their spleens to extract their B lymphocytes or lymphoblasts. These cells are subsequently merged with cancerous cells extracted from a murine (mouse) myeloma. “This produces a conglomerate of hybrid cells called a hybridoma,” explains Peroni. “It is capable of ‘infinite’ growth in a culture environment because of its cancer cells, and it is also able to produce antibodies, obtained from the B lymphocytes in the mouse spleen. This way, you can produce antibodies while using a smaller number of laboratory animals.”

According to Peroni, the choice of whether to produce poly or monoclonal antibodies depends on the technique and final objective. “Some antigens are very similar to each other, so using a monoclonal antibody is the best choice in these cases because it permits selecting the most specific clones,” he says. “When the antibodies’ intended use requires homogeneity and large-scale production, monoclonals are usually a good option because when you have a hybridoma, you can produce the antibodies in a culture medium and then purify them. Also, these antibodies will always be identical to the original, guaranteeing reproducibility and specificity during testing.”

When it comes to diagnosing Asian soybean rust, the company can use either poly or monoclonal antibodies. The tests conducted to date, using the Elisa method, used both types of antibodies. Elisa is a technique used in immunological assessments to detect an antigen or an antibody in a sample, based on the interaction between the two. If one of them is present, a visible sign – such as a color change – is produced and detected by a spectrophotometer. Despite the good results obtained by this method in diagnosing Asian soybean rust, Rheabiotech ran into problems when testing it in the field. “Though simple, this type of test requires some supporting elements, such as a refrigerator, microplate reader, and someone who can interpret the results. These things are normally not available at a plantation,” says Peroni. “So we are developing a different kit that uses a strip of nitrocellulose membrane, similar to a pregnancy test.”

Eduardo CesarFreezer for preserving the cell bank at -80ºCEduardo Cesar

For this, Rheabiotech entered a partnership with ParteCurae Analysis, which operates in the agricultural, environmental, biotechnological, and veterinary industries, producing a range of items that includes quick diagnosis kits for animal and plant diseases. The Asian soybean rust detection kit will contain a strip with antibodies deposited in two specific positions. “One of them will contain the antibodies against the target antigen (test region), in this case the mycelium of Phakopsora pachyrhizi,” explains molecular biologist Regiane Travensolo Sacomano, a researcher at ParteCurae. “The other will contain antibodies against the ‘conjugates’ (control region).” She explains that the conjugates in the kit are secondary antibodies that specifically target the primary antibodies. The conjugates are marked with an enzyme or other substance that makes the reaction visible. In other words, there are two types of antibodies in the test kit. The primary antibodies react against the fungal antigen. And the secondary, marked antibodies react against the primary antibodies, making the entire reaction visible. The markers used in the kit developed by ParteCurae are gold nanoparticles.

During the diagnosis procedure, the antigen-antibody conjugate migrates through the membrane (test strip) until it reaches the test and control regions. “If two red lines appear, it means that the result is positive, that is, the leaf sample is contaminated by the fungus,” says Sacomano. “Negative results will be visible as a single red line, the control line, which is a way of showing that the test is working properly.” A complete diagnosis takes 10 minutes.

Major losses

Using a similar process, Rheabiotech is developing kits for detecting two types of viruses that afflict potatoes, namely potato virus X (PVX) and potato virus Y (PVY). The polyclonal antibodies against these viruses were developed by master’s degree student Marcel Salmeron Lorenzi, advised by Professor Dagmar Ruth Stach-Machado from the Biology Institute at the University of Campinas (Unicamp). The technology was licensed by the company, which is now working to transform it into a commercial product. In Brazil, potato crops occupy a total of about 130,000 hectares, yielding approximately 2 million metric tons per year. In recent years, however, these crops have suffered major losses on account of PVX and PVY. “They damage the leaves and stain the potatoes,” says Peroni. According to Stach-Machado, these viruses are a serious problem. “In Brazil, the diseases caused by these viruses are among the biggest hindrances to increases in production,” she says.

Between 2004 – when Rheabiotech was still called Imuny – and 2014, the company received approximately R$1.3 million from FAPESP through the Innovative Research in Small Businesses Program (PIPE). The funds were targeted not only at these two projects for producing diagnostic tests for specific microorganisms, but also a third project to develop secondary and conjugate antibodies. In 2008, Peroni joined Imuny founder Rojas and together they created Rheabiotech, with the goal of bridging the gap between academic research and the market.

Between 2004 – when Rheabiotech was still called Imuny – and 2014, the company received approximately R$1.3 million from FAPESP through the Innovative Research in Small Businesses Program (PIPE). The funds were targeted not only at these two projects for producing diagnostic tests for specific microorganisms, but also a third project to develop secondary and conjugate antibodies. In 2008, Peroni joined Imuny founder Rojas and together they created Rheabiotech, with the goal of bridging the gap between academic research and the market.

Projects

1. Development of diagnostic kits for phytopathogens of agricultural importance (nº 2008/53621-4); Grant mechanism Innovative Research in Small Businesses Program (PIPE); Principal investigator Luís Antônio Peroni (Rheabiotech); Investment R$386,992.10 (FAPESP).

2. Antibody production for immunochemical methods – market insertion (nº 2012/51000-8 and nº 2013/50045-0); Grant mechanism Innovative Research in Small Businesses Program (PIPE); Principal investigator Fernanda Alvarez Rojas (Rheabiotech); Investment R$256,094.26 (FAPESP) and R$252,000.00 (Finep).