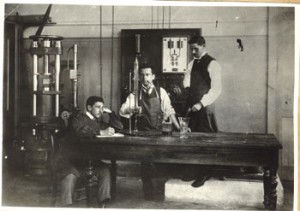

IPTThe Gabinete de Resistência de Materiais lab, in 1904IPT

Celebrating its 110th anniversary in June, the Instituto de Pesquisas Tecnológicas/IPT technological research institute is investing in a new vocation. Accustomed to responding to the demands of society and industrial development, such as conducting essays on materials or preparing expert reports on accidents at construction works, the IPT now wants to take on the role of networking agent for solutions on major technological matters, thus anticipating the needs of the public and private sectors. The Centro de Pesquisas de Estruturas Leves, a research laboratory for light research, which IPT plans to inaugurate in the Parque Tecnológico de São José dos Campos, Technological Complex, located in the city of São José dos Campos by December, is a symbol of this new model. The lab will focus on the research and development of new materials and metal structures. The objective is help Brazil develop materials that will reduce the weight of airplanes, thus dominating a crucial technology for competitiveness in the aerospace industry, with possible applications in the automobile and oil industries as well. With total investments amounting to R$ 90.5 million, the initiative was made feasible thanks to a partnership involving FAPESP, IPT, the São Paulo State Secretary of Development, Empresa Brasileira de Aeronáutica/Embraer company and the Banco Nacional de Desenvolvimento Econômico e Social/BNDES federal government Bank for Social and Economic Development.

“The IPT is bringing together and negotiating with funding agencies and attracting skilled professionals from universities to develop technologies that solve the industrial sector’s complex problems”, says João Fernando Gomes de Oliveira, the institute’s director president and professor of the University of São Paulo/USP’s São Carlos School of Engineering. He says that the idea of the lab did not come from the IPT, but set a course for the institute. “We concluded that our importance in the future will depend on our involvement in major structuring projects such as this one”, says João Fernando. Another project is already in the pipeline – the biomass gasification laboratory, scheduled for opening in five years at the Parque Tecnológico de Piracicaba technological complex. The lab will network the efforts of companies and public investments to overcome the technological bottlenecks in the production of second-generation ethanol.

The objective is to make it feasible to transform the cellulose, which is in the sugar cane bagasse and the straw discarded during harvesting, into combustible ethanol, by means of converting the cellulose into biomass gas and subsequent liquefaction of the gas into ethanol. This kind of technology, which is expected to multiply the productivity of Brazilian sugar cane, is the object of a huge research effort, especially in the United States and Europe. The consortium interested in the IPT’s lab includes Braskem, Petrobras, the Centro de Tecnologia Canavieira/CTC Sugar Cane Technology Center and the União da Indústria da Cana-de-açúcar/Única Sugar Cane Trade Association. The units in the cities of São José dos Campos and Piracicaba will join a structure whose facilities are distributed throughout 67 buildings that take up more than 96 thousand square meters in the cities of São Paulo, Guarulhos and Franca. The institute’s staff comprises approximately 500 researchers and more than 400 technicians.

Other matters are being evaluated by the institute, such as the improvement of technologies for the production of solar cells and wind energy turbines. “We are setting up a new department coordinated by a director, who will be in charge of prospecting major themes, with the potential for technological demands and to attract partners”, says João Fernando. The jump shot for the change in the profile was the substantial increase in public investments in the activities of the IPT. Until recently, annual investments in the institute had corresponded to R$ 3 to R$ 5 million; most of the funds came from the private sector. The sum of R$ 150 million is being invested in the institute’s modernization in the period from 2008 to 2010, of which R$ 120 million will be provided by the São Paulo State government.

The new profile desired by the IPT follows an international model. João Fernando Gomes de Oliveira mentions the example of the Korea Advanced Institute of Science and Technology (Kaist), one of South Korea’s biggest research institutes. Currently involved in cutting-edge technology projects, such as the development of ultra-resistant plastic material and the design of movable ports to unload huge container ships at sea. The sizes of these container ships are becoming increasingly less compatible with the drafts of traditional ports. “The ambition of the IPT is, proportionally similar. We know that innovation is an on-going process that demands several stages. There is a missing link in the innovation process in Brazil: the funding and simulation of tests able to show that the researchers’ good ideas will have a practical application for companies. It is in this is the space we want to take action”, he states.

Concrete and asphalt – Adapting to the needs of each era is a distinctive feature of the IPT’s longevity. Created in 1899 as the Polytechnic School’s Gabinete de Resistência de Materiais, Materials Resistance Department, the institute’s objective was to conduct essays with construction materials, such as concrete and asphalt, which were imported at that time. From 1926 onwards, the institute was called Laboratório de Ensaios de Materiais, Materials Lab, and in 1934, it received its definitive – and current – name. In the course of its existence, the institute was engaged in missions of all kinds, such as directions on how to manufacture hand grenades for the rebels from São Paulo State in 1932; the development of wood plates for the manufacturing of small airplanes in the 1940s; and the adaptation of car engines to use syngas during the gasoline shortage in the Second World War. From the 1950s onwards, the institute participated in the projects of the big hydroelectric power plants and, two decades later, in the construction of the first subway line in the capital city of São Paulo.

In the last 20 years, the IPT also dedicated its efforts to environmental projects and to partnerships with small and medium sized companies that cannot afford to maintain their own research & development departments. The work that attracts the most attention from the public, however, are the expert reports prepared by the institute’s technicians in disasters such as the collapse of the construction work on a subway station two years ago, which killed seven people. “The ideal situation would have been for the IPT to have been invited to participate in the preparation phase of the project and in the supervision of the construction work, instead of having to do archaeological work to define the causes of the tragedy”, says João Fernando Gomes de Oliveira. “But we cannot avoid this mission of acting as the ‘technical police’ because we are the most highly qualified institution to do such investigation in the state and most of our funding comes from the government.”

Republish