FAPESP’s Technological Innovation in Small Businesses program (PIPE) is celebrating its 20th anniversary as a pioneering platform supporting technology-based companies in Brazil. In the last two decades, the program has provided 1,921 grants, 2,959 associated scholarships, and around R$400 million in funding for projects at roughly 1,200 micro, small and medium-sized enterprises in São Paulo State. Created to support technological innovation and encourage in-company research, PIPE has supported entrepreneurs looking to leverage science in new products or services. It often fosters innovation at one of the most critical periods in a company’s life—its beginnings.

FAPESP’s Technological Innovation in Small Businesses program (PIPE) is celebrating its 20th anniversary as a pioneering platform supporting technology-based companies in Brazil. In the last two decades, the program has provided 1,921 grants, 2,959 associated scholarships, and around R$400 million in funding for projects at roughly 1,200 micro, small and medium-sized enterprises in São Paulo State. Created to support technological innovation and encourage in-company research, PIPE has supported entrepreneurs looking to leverage science in new products or services. It often fosters innovation at one of the most critical periods in a company’s life—its beginnings.

“PIPE has combined technological innovation and merit-based opportunity to become the leading startup support program in Brazil,” FAPESP President José Goldemberg said at the 20th anniversary ceremony on June 30. “The program was described by BNDES [Brazilian Development Bank] officials on a recent visit as “a huge aquarium where investors are eager to pick their favorite fish.”

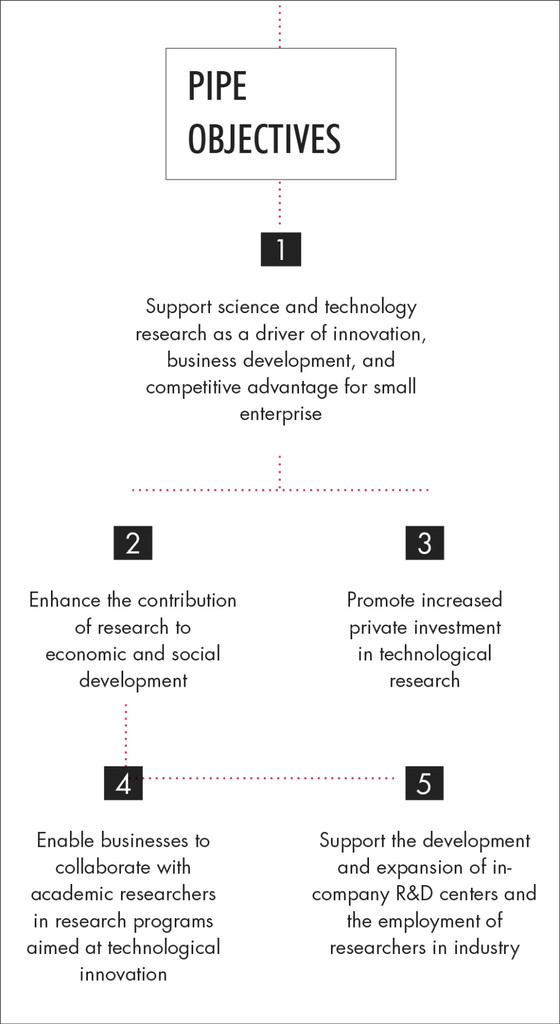

The program has consistently invested in research that has created both economic and social impact. Besides creating job opportunities and boosting local economies in host municipalities, PIPE-funded businesses have developed hundreds of innovative products and services. These range from tethered surveillance balloons for major events and border security, industrial automation systems and biological crop protection products to weather and air-traffic control radars, medical devices, and voice and facial recognition systems.

According to FAPESP Scientific Director Carlos Henrique de Brito Cruz, who oversaw the launch of the program as then-president of FAPESP, PIPE was instrumental to São Paulo State’s aspiration to become a global hub for startups and small technology-intensive firms. “PIPE has also helped bring research into the business setting. And in doing so, it has created employment opportunities for researchers in small businesses and contributed to economic development in São Paulo State and throughout Brazil,” he said.

From 2010 to 2012, submissions and proposals declined in both number and quality, resulting in fewer grants. In 2012 it became a policy at FAPESP to organize “Small Business Innovation Dialogs” in advance of the proposal submission deadline to provide clarification on the program to potential applicants. The number of calls for proposals each year also increased to four, further enhancing the program.

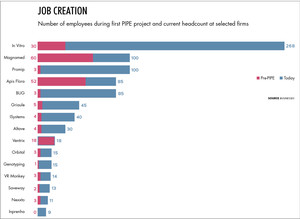

According to Sérgio Queiroz, a professor at the University of Campinas (UNICAMP) and assistant coordinator for research and innovation at FAPESP, many supported businesses have already reached a high level of maturity, growing their revenues exponentially and launching a range of innovative products. Among these are Griaule, a firm developing fingerprint recognition software and algorithms such as those used in Brazil’s electronic voting terminals; Promip Manejo Integrado de Pragas, a company developing pest control products for vegetable growers; and I-Systems, a developer of software systems using artificial intelligence for process control at companies such as Coca-Cola, Braskem, Ambev, and Suzano. Other businesses, Queiroz says, are still developing. These include Braincare, a manufacturer of medical devices and clinical monitoring sensors; Inprenha, a biotechnology company in the animal breeding segment; and VR Monkey, a provider of virtual reality solutions.

Inspiration from a predecessor

Inspiration from a predecessor

When it launched the PIPE program, FAPESP made research history, becoming the first research-funding agency in Brazil to provide non-repayable funding directly to small businesses. PIPE required funded research projects to be done within beneficiary companies and that they develop a product, process, or service with innovative potential. As noted by José Fernando Perez, FAPESP’s scientific director at the time, the program made businesses the locus of innovation, a concept then unprecedented in Brazil.

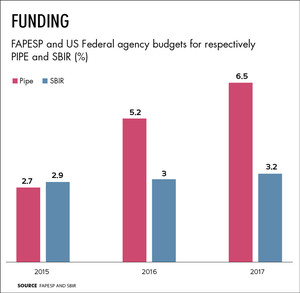

PIPE drew inspiration from the Small Business Innovation Research (SBIR) program created by the Small Business Innovation Development Act in 1982 to support innovative research and development (R&D) at small and medium-sized businesses in the United States (see article). SBIR is administered by 11 government agencies—including the National Science Foundation (NSF)—which allocate 3.2% of their R&D budgets to the program. In terms of percentage, FAPESP allocates twice as much (see chart) to its counterpart, PIPE.

Researcher and professor Alcir José Monticelli (1946–2001) of the School of Electrical Engineering at UNICAMP was the first to suggest that FAPESP create a program similar to SBIR. In 1996, on a visit to advise the NSF on selecting SBIR grant recipients, he immediately realized how important it would be to develop a similar program back home to catalyze innovation and knowledge transfer from academia to the business world.

On returning to Brazil, he shared his thoughts with José Fernando Perez. In a short space of time, his proposal was crafted into a program and approved by FAPESP’s Board of Trustees. During the program launch ceremony on June 18, 1997, Governor Mario Covas said: “The Foundation will be a highly important and effective tool in assisting these [technology-based] firms. FAPESP needs to remain aggressive in terms of not waiting for research demand to come its way, but instead driving, anticipating, and promoting R&D.”

During the ceremony, Brito Cruz stressed the importance of the program, noting that: “Locally developed science needs to translate into GDP [Gross Domestic Product], and GDP is driven by industry. So more than ever, the challenges of competing in a globalized world mean science and technology need to be embedded in value chains.”

Through PIPE and the Partnership for Technological Innovation program (PITE), implemented in 1995, the Foundation built an innovation culture in São Paulo that has since been replicated by other development agencies across Brazil. PITE provides funding for university research projects that are developed in collaboration with, and are cofunded by, corporate research centers in Brazil or other countries.

PIPE uses a gated, three-phase program structure. Phase 1, with a duration of nine months, involves research projects at an initial stage and is intended to establish the technical and commercial feasibility of innovations proposed to solve a research problem. In phase 2, which can last up to two years, the research project proper is developed and may progress to the point of building a prototype, for example. When the program was first created, the funding limit for phases 1 and 2 was respectively R$50,000 and R$200,000. In 2015 the Foundation raised the ceiling to respectively R$200,000 and R$1 million.

Phase 3 involves the final development of the innovation into a product or service and placement on the market. Because under its by-laws the Foundation is permitted only to fund research and not the development of commercial products, this stage is carried out in collaboration with partner agencies, hitherto the Brazilian Funding Authority for Studies and Projects (FINEP), the agency managing the Support for Research in Businesses Program (PAPPE).

Phase 3 involves the final development of the innovation into a product or service and placement on the market. Because under its by-laws the Foundation is permitted only to fund research and not the development of commercial products, this stage is carried out in collaboration with partner agencies, hitherto the Brazilian Funding Authority for Studies and Projects (FINEP), the agency managing the Support for Research in Businesses Program (PAPPE).

The FAPESP-FINEP collaboration to support phase 3 PIPE projects was agreed in 2004 and materialized as the PAPPE-PIPE III program. Its first call for proposals selected 20 businesses for support. Managed by FINEP in partnership with State Research Foundations (FAPs), PAPPE provides funding for innovative product and process R&D efforts undertaken by researchers working directly or in collaboration with technology-based firms. In addition to supporting phase 3 projects within PIPE, the program also issues calls for proposals targeting specific research interests (see article).

The largest portfolio do date

FAPESP has from time to time implemented changes in its program rules and policies. Originally, researchers were eligible to receive program funding if they were linked to small businesses with up to 100 employees based in the state of São Paulo. PIPE eligibility was later extended to companies in São Paulo with up to 250 employees. The number of calls for proposals also rose from two to four per year (one every three months). The program began with an annual funding allocation of what today would amount to R$2.5 million, and currently has a budget of R$60 million for phases 1 and 2.

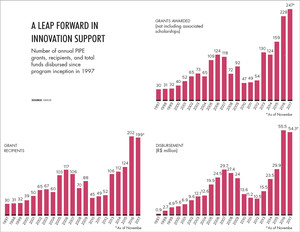

Out of total program grants as of late November this year, 1,941 are phase 1 and 2 projects. The remaining 97 are in phase 3. In its first year, PIPE selected just 30 project candidates, awarding a total of R$1.3 million in investment. Of the successful candidates in the single call for proposals in 1997, many were firms engaged in research on fiber optics and computer systems, followed by businesses in the field of biology and especially genetics.

A decade later, the number of grants had leaped to 118 in the year, and funding disbursements to around R$30 million (see charts). This year the program is looking to outperform 2016’s 228 proposals and R$55.5 million in funding, PIPE’s best results to date. “We awarded virtually one research grant for every working day in the year,” says Brito Cruz, underlining the Foundation’s efforts to expand the program despite the financial crisis in Brazil and the toll it took on FAPESP’s budget.

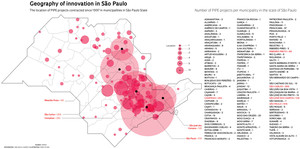

To date, companies from 127 municipalities have received research funding through PIPE. Most are located in major research and innovation centers that are home to large universities and research institutes, such as São Paulo, Campinas, São Carlos, São José dos Campos and Ribeirão Preto. But program funding has also found its way to small but economically vibrant cities like Botucatu, São José do Rio Preto, Sorocaba, Piracicaba, Jaboticabal, Mogi Mirim, Santos, Paulínia, Araraquara and Diadema. “That these projects will emerge where the top universities and research institutions are is to be expected. Technology-based innovation doesn’t arise in a vacuum,” explains Brito Cruz.

But even with the benefit of PIPE funding, the journey a small technology-based firm must travel to develop and grow is not without perils. An assessment of 214 PIPE projects developed in the first decade of the program (1997–2006) by 185 firms showed an 8% mortality rate in the total sample of supported companies. The rate was highest among firms created ad hoc to submit PIPE applications (22%). But these rates were well below the 70% average for technology-based businesses at the time, as reported by the Brazilian Small Business Support Service (SEBRAE). One of the main reasons entrepreneurs cited for going out of business was the difficulty obtaining funding for operating and capital expenditure.

But even with the benefit of PIPE funding, the journey a small technology-based firm must travel to develop and grow is not without perils. An assessment of 214 PIPE projects developed in the first decade of the program (1997–2006) by 185 firms showed an 8% mortality rate in the total sample of supported companies. The rate was highest among firms created ad hoc to submit PIPE applications (22%). But these rates were well below the 70% average for technology-based businesses at the time, as reported by the Brazilian Small Business Support Service (SEBRAE). One of the main reasons entrepreneurs cited for going out of business was the difficulty obtaining funding for operating and capital expenditure.

Conducted by UNICAMP’s Laboratory for Studies on the Organization of Research and Innovation (GEOPI), the survey found that PIPE had had an impact on several fronts. Around 60% of evaluated projects had created technological innovations, a rate generally deemed satisfactory. Of a total of 111 innovations, 59 were novel at a national level, 17 at a global level, and 29 at the company level. “These innovations were essentially oriented to products, followed by software and processes. All were technology-based innovations and therefore consistent with PIPE’s founding mandate,” explains Sérgio Salles-Filho, a coordinator at GEOPI.

The survey also found that 52% of the 214 projects would not have existed had they not received PIPE funding—SBIR, the program’s US counterpart, has reported a similar percentage of 65%. Some supported firms—12 to be precise—were spin-offs from other companies. The survey found, however, that 23 new startups had been created, of which 21 credited PIPE with playing a vital role in their development.

Supported firms saw a 40% increase in the number of formal employees. PIPE projects also helped create skilled job posts and led to an increased number of company employees with undergraduate degrees (60%) and PhDs (91%).

A fresh PIPE assessment report being developed for the period 2007 to 2016 will also benchmark project outcomes against peer programs in countries such as the US, France, and Japan. “PIPE will be monitored continuously, with data collected at project close and two years subsequent,” says Salles-Filho.

Future challenges

Future challenges

While recognizing the program’s success in its first 20 years, Brito Cruz is now focused on the challenges lying ahead. “FAPESP hopes that in the coming years supported firms will set global ambitions for their research efforts, leading to the development of a new generation of São Paulo–based firms that are uniquely attractive to international investors. But to achieve this would require developing world-class products. This will be our biggest challenge over the next 10 years,” says the FAPESP scientific director.

The Foundation is considering a number of initiatives toward these goals. The first is a small business innovation program aimed at supporting the development of disruptive technologies. “We recognize how meager innovation rates are in Brazil and hope to tackle this head on,” says Carlos Américo Pacheco, CEO of FAPESP’s Executive Board.

The second is internationalization, helping supported firms incubate or locate in other countries. “We will explore opportunities to work with partners around the world to help São Paulo firms reach new heights on the global scene,” says Pacheco.

Lastly, FAPESP plans to further establish PIPE’s presence in the venture capital, angel investment, accelerator and incubator arena. “We’re still too isolated both in terms of connections with large corporations managing investment funds and in terms of innovation networking,” says the FAPESP chief. “Working more closely would be beneficial both to PIPE and to the broader ecosystem.”

Producing monoclonal antibodies at the Butantan Institute, Recepta Biopharma’s research partnerLÉO RAMOS CHAVES

Antibodies to fight tumors

This year Recepta Biopharma celebrated US pharmaceutical company Mersana’s successful animal model results for a novel drug for cancer treatment. The drug, which in December proceeded to clinical trials in human patients, was created from a monoclonal antibody (RebmAb 200) developed by the Brazilian firm in collaboration with the Butantan Institute, building on an earlier project funded by the Partnership for Technological Innovation program (PITE) (see Pesquisa FAPESP, issue No. 204). “This is Brazil’s first internationally licensed drug patent for cancer treatment,” says physicist José Fernando Perez, a director at Recepta. The original antibody, isolated from rodents, was licensed to the Brazilian researchers by the Ludwig Institute for Cancer Research in New York and modified in Brazil to be tested in humans (or “humanized,” in technical jargon). Successful licensing and testing progress have helped to secure Recepta’s first revenues of R$8 million since the firm was created in 2006. “Our success owes much to the value and knowledge provided by the earlier PITE-supported project,” he says. If approved, Recepta will own marketing rights to the drug in Brazil and intends to supply it at more affordable prices to the national health care system.

The company was also awarded a PIPE-funded project in which it developed an antibody for treating central nervous system tumors. The feasibility studies, however, did not support continued investment. As often happens in science, some projects will prove unsuccessful, while others will take years to develop into products. Recepta has 16 employees, 13 of which are dedicated to research.

At the cutting edge of the aerospace industry

PIPE-supported firms develop equipment for satellite and weather radar systems

In the early 2000s, four companies attracted notice for their locally designed and developed instruments for satellite and radar systems. Omnisys, Orbital, Orbisat (now Bradar), and Equatorial Sistemas produced technologies that were then in short supply in Brazil, largely destined for the Brazilian Space Program. All were supported by the PIPE program. Founded in 1997 by three electronics engineers, Omnisys, of São Bernardo do Campo, specialized in the development of weather radars for aviation applications (see Pesquisa FAPESP, issues No. 117 and No. 212). In all, the firm has been awarded 15 PIPE projects. In 2006, the company was acquired by French-based defense, security and aerospace contractor Thales Group. Omnisys also developed components for the China-Brazil Earth Resources Satellite (CBERS) and the Amazônia-1 environmental monitoring satellite programs.

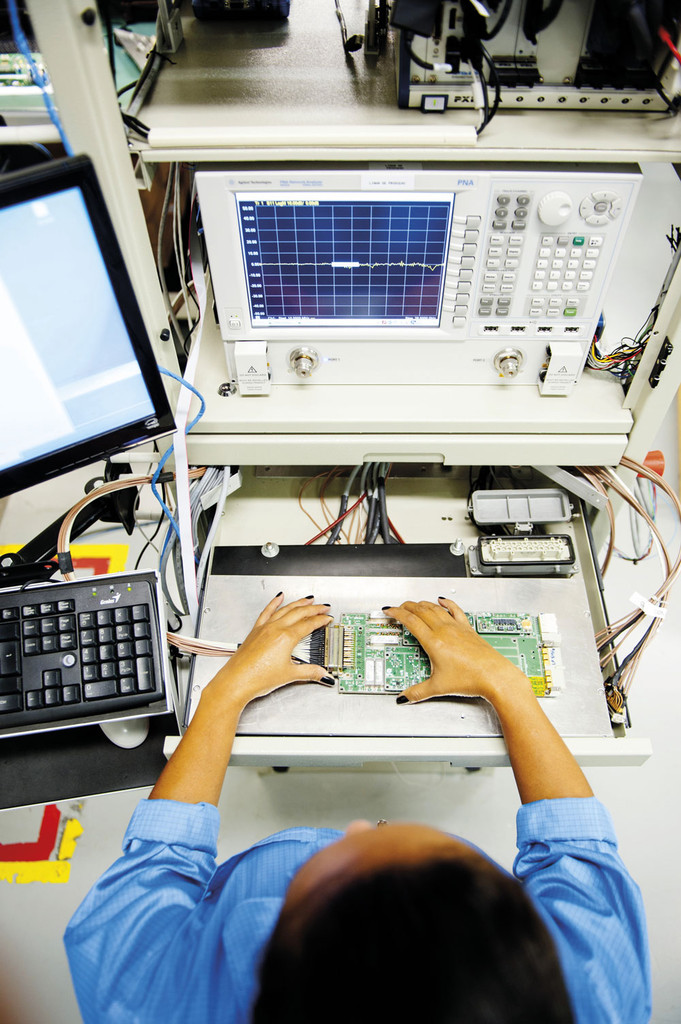

Like Omnisys, Orbisat and Equatorial of São José dos Campos were later acquired by larger corporations. Orbisat was renamed Bradar when in 2011 it became a division of the Embraer Defense & Security conglomerate. The company, which specialized in developing electronic systems and sensors such as air and ground surveillance radar systems, carried out three PIPE projects between 1999 and 2015 (see Pesquisa FAPESP, issues No. 149 and No. 231).

A researcher testing electronics for a radar system designed by Embraer Group’s BradarLÉO RAMOS CHAVES

Created in 1996, Equatorial received funding support through seven PIPE programs, developing a range of equipment and operating systems for the CBERS, the Amazônia-1, and NASA’s Acqua satellite, launched in 2002. Four years later, European multinational Airbus acquired a controlling interest in Equatorial. In 2017, Airbus sold its stake to Brazil’s Akaer, a contractor working on the Swedish Gripen fighter program for the Brazilian Air Force (FAB). Equatorial also develops equipment for Sirius, a light source being built by the Brazilian Synchrotron Light Laboratory (LNLS) in Campinas (see Pesquisa FAPESP, issues No. 61 and No. 234).

Another São José dos Campos firm, Orbital, develops propulsion technology for small rockets, including ethanol-fueled engines, in collaboration with the Brazilian Aeronautics and Space Institute (IAE). Founded in 2000 and with eight PIPE grants to date, the firm has produced solar panels and other on-board systems for the CBERS and Amazônia-1 satellite programs.

Orbital is part of the technology transfer program for the Brazilian Government’s Geostationary Defense and Strategic Communications Satellite (SGDC) project. The company was selected as an SGDC recipient of technology for building satellite power systems and solar generators. The satellite, which was launched into orbit this year, was produced by Franco-Italian aerospace manufacturer Thales Alenia Space (see Pesquisa FAPESP, issues No. 99 and No. 256).

Altave balloons are used for surveillance in large-scale events and to provide internet and mobile telecommunications in remote locationsEDUARDO CESAR

Internet and surveillance with tethered balloons

Altave, in São José dos Campos, has developed a range of tethered balloons carrying surveillance cameras and communications devices for remote locations without access to telecommunications or internet service. Founded in 2011 by engineers Bruno Avena and Leonardo Nogueira after they graduated from the Technological Institute of Aeronautics (ITA), the company has delivered broadband and surveillance capabilities to events in rural areas, as well as the 2013 Confederations Cup in Brazil and the Rio 2016 Olympic Games.

The systems were deployed at these events to monitor the venues and surrounding areas with airborne cameras, some with high resolution and zooming capabilities. Four balloons, or aerostats, were deployed for the Olympics, each with 13 on-board cameras. The aerostats are tethered between 50 and 200 meters (m) above the ground. For internet applications, they receive the signal from ground equipment and broadcast it to areas without an internet connection (see Pesquisa FAPESP, issue No. 257).

Since 2011, the company has been awarded 10 PIPE grants to develop tethered balloon systems, ground equipment, and proprietary control software. In 2016 the firm grossed R$13 million. Of its 30 employees, 21 are involved in R&D. This year Altave made an agreement with Airstar Aerospace, a French balloon manufacturer, to distribute its aerostats in Europe. Altave has also taken its balloons to Argentina for a trial demonstration of mobile phone service delivery in the event conventional systems are down.

Griaule specializes in digital identification systems such as those used by Brazil’s Electoral Justice Departmentléo ramos chaves

Advanced identification and information systems

Software and sensors improve voting system reliability and enhance process control

Three PIPE grant recipients—Griaule and I-Systems, in Campinas, and Nexxto, in São Paulo—have developed advanced Internet of Things and artificial intelligence capabilities. Founded in 2002, Griaule posted revenue of R$40 million last year. The company has developed and supplied the technology used in electronic voting machines in Brazil (see Pesquisa FAPESP, issue No. 255), and has been selected to provide the digital identification software currently being implemented by Brazil’s High Electoral Court (TSE).

The firm has also developed face and palm recognition technology used by companies in Brazil, the US, Israel, Argentina, Mexico, and India, and currently exports products to 74 countries worldwide. Griaule has received funding for three PIPE projects, the first in 2003. It then had just five employees, and now has 45, half of which are dedicated R&D staff.

Nexxto was founded in 2010 under the name Rfideas as a developer of RFID (radio frequency identification) tags. RFID tags are used to identify, track, and manage computer equipment such as desktop and laptop computers. They are also used on personal identification badges and on product packaging for tracking during transportation from factory to recipient.

Nexxto was awarded two PIPE grants to develop its technology. In 2015, it developed a system that uses internet of things principles to monitor temperature and humidity in cold food storage applications such as freezers, refrigerated counters and cold rooms (see Pesquisa FAPESP, issue No. 259). The system, which is supplied primarily to supermarkets and restaurants, sends mobile notifications in the event that cold storage systems are shut off due to a power outage, for example. The company made R$2.2 million in revenue in 2016, the year it first exported its technology to Uruguay. Nexxto has 11 employees, five dedicated to R&D.

I-Systems specializes in software and sensor systems using artificial intelligence for process control. One of the first commercial applications for the technology was in soft drink bottle filling processes. Because bottling machines are generally unable to fill bottles with the exact amount specified on the label, manufacturers will typically set up the bottling process to add 5% more product. I-Systems developed a solution allowing bottlers to regulate their machines to inject only 1% more than the amount noted on the label, saving 4% per bottle (see Pesquisa FAPESP, issue No. 211).

The company also provides solutions for equipment control systems, such as focus control in video cameras. The firm was founded in 2004 by four partners—three computer engineers and a mathematician—all alumni from the University of Campinas (UNICAMP). Of the company’s 40 employees today, nine are actively engaged in innovation.

Biological pest control in agriculture

Three supported companies develop insect, mite and fungi to replace pesticides

Brazil’s biological pest control sector is growing at rates of between 15% and 20% per year according to estimates from the Brazilian Association of Biological Control Companies (ABCBIO), and is expected to see even faster growth as farmers increasingly use insects, fungi, bacteria and viruses—instead of pesticides—to fight pests. Two small São Paulo firms—Bug and Promip, both founded in the previous decade by alumni from the Luiz de Queiroz School of Agriculture at the University of São Paulo (ESALQ-USP)—have developed and brought to market a range of insects and microorganisms suited for a variety of crops.

Bug, in Piracicaba, produces four species of small wasps that prey on important pests of sugarcane, corn, soybean, tomato, and sorghum crops (see Pesquisa FAPESP, issue No. 195). Founded in 2001, it received PIPE-awarded funding for three research projects. Since 2009, it has received investment on three occasions from venture capital funds, totaling R$9 million. Bug has 85 employees, including three dedicated to R&D, and last year reported sales of R$12 million.

Promip started business in 2006 in Limeira and today has units in Engenheiro Coelho and Conchal, all in the state of São Paulo. The company produces three species of mites for vegetable, fruit, flower, and mushroom plantations, as well as two wasp species for sugarcane and soy. “One of the company’s research interests is the commercial production of stingless native bees for pollination,” says Marcelo Poletti, a partner at Promip (see Pesquisa FAPESP, issue No. 236). The company has been awarded six PIPE projects since inception. In 2014, it received R$4 million in funding from Fundo de Inovação Paulista, an innovation fund established by the São Paulo Development Agency (Desenvolve SP). The company generated revenues of R$9 million in 2016 and has 100 employees, 30 of which are involved in R&D.

Dutch company Koppert Biological Systems, a two-time PIPE grant recipient and a leading biological control firm, with a presence in 26 countries, established operations in Piracicaba, São Paulo, in 2011. The company produces fungi solutions for agriculture as well as predatory wasps and mites for a variety of crops. In 2016 the company reported R$45 million in revenue and reached an agreement with FAPESP to create an Engineering Research Center linked to the Partnership for Technological Innovation program (PITE). Among the center’s research projects for which calls for proposals have been launched are processes for the production, large-scale automation, and development of new organisms originating from Brazilian biodiversity.

Electronic tire monitoring tags

Campinas-based Saveway has developed an electronic tire wear monitoring tag system for trucks, buses, and agricultural machinery. The solution is designed for trucking companies, sugarcane mills, and bus companies managing large fleets and therefore tens of thousands of individual tires. Tires are typically retreaded as many as three times at 80,000 to 100,000 kilometer intervals.

Saveway’s tire tags use RFID (radio frequency identification) technology and are installed on the inner wall of the tire. “They use radio frequency signals to transmit an ID number to a proprietary hand-held device,” says mechanical engineer José Caruso Gomes, a partner at Saveway. These numbers tell system users which tires are being used on a given vehicle. Saveway has created a software platform that is used with the tire tags to track tire mileage and log information about tire defects.

“We have developed a robust tag and software system that allows tire repair technicians to quickly identify as many as 60 tire issues and predict when a tire will need to be retreaded,” says Gomes. Saveway was awarded five PIPE projects and partnered with the Renato Archer Information Technology Center (CTI) and the University of Campinas (UNICAMP) to develop the technology. The company has 13 employees and projects sales of R$800,000 this year.

Virtual reality for schools and corporations

With virtual reality as its raw material and education and training as its end product, VR Monkey was founded in 2013 originally as a video game and mobile app developer, but shifted its business two years later to virtual reality content viewed with special head-mounted displays providing visual and auditory immersion. The company’s first virtual reality animation, geared to elementary schools, was As sete maravilhas do mundo antigo (The seven wonders of the ancient world). Then came the series Dinos do Brasil (Brazilian dinosaurs), depicting 15 prehistoric animals that inhabited modern-day Brazil. This material is now among the permanent exhibits at São Paulo’s Catavento Museum.

“The three PIPE projects we had helped us develop technology at larger scale and produce longer animations,” says computer engineer Pedro Kayatt, one of São Paulo–based VR Monkey’s three founding partners. The company’s R$220,000 in sales last year are expected to double in 2017. Of the company’s 14 employees, six have PIPE-awarded scholarships. In addition to educational content, the company provides corporate virtual reality solutions for employee training. Among its clients are the mining division of Votorantim, steel maker Gerdau, and pulp and paper manufacturer Klabin.

Local medical device innovation

New lung ventilators and heart rate and intracranial pressure monitors add to homegrown medical offering

Three PIPE-supported firms have developed new medical products for application areas such as cardiology, pneumology, neurology, and emergency care. The São Paulo company Magnamed has developed and manufactures two types of lung ventilators, one designed to assist patient breathing in intensive care units (ICUs) and the other, a portable model for use in ambulances, to help doctors and paramedics provide first aid to patients with difficulty breathing.

The company, which has worked on five PIPE projects to date, began operation in 2005. Its first device, OxyMag, was launched in 2008 and its second, Flexmag, in 2010 (see Pesquisa FAPESP, issue No. 259). Both are now exported to markets in Latin America and Asia, with outbound sales accounting for 30% of the company’s R$34 million in revenue in 2016. Magnamed employs 15 people—out of a total of 100—in R&D.

Ventrix is currently finalizing the development of a wireless electrocardiography device to be launched in 2018. The device, developed with PIPE-awarded funding, is used to monitor heart rate and arrhythmias outside a hospital or in an emergency setting. Conventional Holter or ambulatory electrocardiography devices have several leads and electrodes that need to be attached to the patient. The Ventrix device is just 8 centimeters (cm) long and 5 cm wide and is attached to the patient via a single electrode. It is fully wireless and transmits data over the internet to a central repository. The company, based in Cotia and founded in 2005, specializes in the manufacture of conventional equipment for cardiology. Last year it reported revenues of R$1.5 million. It has 18 employees, six in R&D. To produce the new heart monitor, Ventrix is setting up a factory in Santa Rita do Sapucaí, Minas Gerais.

Braincare, in São Carlos (see Pesquisa FAPESP, issue No. 221), has developed a portable device for noninvasively monitoring intracranial pressure in trauma, hydrocephalus and stroke patients. The device was designed by physicist Sergio Mascarenhas, a retired professor from the São Carlos Institute of Physics at the University of São Paulo (IFSC-USP), who began developing the device in 2007 and founded the company in 2014. In all, Braincare has developed six PIPE-funded projects. “We’re now finalizing the business plan, adapting the device to our target marketing model, and raising funds for production,” says company CEO Plínio Targa.

Cattle reproduction technology

São Paulo firms excel in embryo production and pregnancy rate enhancement technology

Brazil has the largest cattle population in the world, with 218 million heads of cattle for beef, dairy, and leather production. Recently, new productivity-enhancing technologies have been developed for the sector by two firms relying on PIPE funding. In Vitro Brasil (IVB), a company founded in 2002 in Mogi Mirim, has been awarded five PIPE projects to date. The company specializes in in vitro production of bovine embryos of high genetic quality and has created a media manufacturing system that extends shelf life to 60 days. Before, fresh culture media had to be produced every week (see Pesquisa Fapesp, issue No. 231).

“Other process enhancements, such as improved cryopreservation [embryo freezing], have firmly established the company as the world’s leading producer of bovine embryos, with a global market share greater than 50%,” says Andrea Basso, head of research and development at IVB. “These technologies have allowed us to ship frozen embryos to more distant locations, opening doors to a new market.”

According to Basso, thanks to the company’s newly developed system, a rancher in the Northeast of Brazil, for example, can purchase embryos from high-performance herds in São Paulo and Minas Gerais and have a genetically renewed herd in less than a year. In 2015, the company was sold for R$90 million to US-based bull spermatozoa producer ABS Global. IVB has retained its name and business activities, has 268 employees, and recorded revenues of R$28 million in 2016.

Inprenha, a nine-person company in Jaboticabal and a recipient of four PIPE grants, developed a new method for improving success rates in artificial breeding techniques. The company used a lectin protein present in various mammalian tissues to formulate a biological product that has proven to increase pregnancy rates in tests on cattle, buffalo, and goats.

“We used the recombinant bacteria method to produce a protein for use in breeding techniques such as in vitro fertilization and artificial insemination,” says Inprenha production director Marcelo Roncoletta, noting that the new method has successfully improved pregnancy rates in cattle by 7% to 14% across the different techniques. The product is soon to be launched on the market pending registration with the Ministry of Agriculture. A spin-off from Top in Life, a São Paulo company specializing in goat and sheep semen and embryos, Inprenha has now begun studies toward testing the product in humans.

Identification of yeasts

A study on the genetics of the yeast Saccharomyces cerevisiae, conducted as part of biomedical engineer Débora Colombi’s postdoctoral research at São Paulo State University (UNESP), led to the creation of Genotyping, a biotechnology firm in Botucatu that posted sales of R$1.5 million in 2016. “With a 15-strong team today, the company was founded after the award of our first PIPE project in 2008,” says Colombi. Saccharomyces is used to ferment sugarcane juice in the production of ethanol. Ethanol plants purchase selected strains of the microorganism that are optimal for production, but face problems when rogue yeasts carried from the cane fields on harvested cane stalks decrease production efficiency.

“We developed a method based on microsatellites [short repeat motifs in the genome of a species that function as markers for genetic variation] to identify each yeast strain in the fermentation vats [where sugarcane juice is mixed with yeast],” says Colombi. The plants bring samples from each vat to our company for analysis. If there is a prevalence of non-productive yeasts, all the material in the relevant vat will need to be replaced.

Genotyping has been awarded five PIPE projects so far, mostly involving the development of molecular markers to distinguish yeast strains and testing kits for easier and faster identification of microorganisms. Researchers from the company are now analyzing bacteria that feed on sugarcane juice and compete with Saccharomyces, with adverse effects on production.

In 2015, Genotyping received funding from the São Paulo Innovation Fund under Desenvolve SP, in partnership with FAPESP, the Brazilian Funding Authority for Studies and Projects (FINEP), the Brazilian Small Business Support Service (SEBRAE) in São Paulo, and the Development Bank of Latin America (CAF).

At the fund’s suggestion, Genotyping became a holding company providing human genetic testing services, but without discontinuing its yeast identification business. The company’s offering now comprises paternity tests and screening for rare and hereditary diseases, which since 2016 have been covered by health insurance plans in Brazil. Another company belonging to the group, Biotecnologia Pesquisa e Inovação (BPI), conducts R&D and offers the services that Genotyping originally developed for applications in agriculture, manufacturing, universities, and research institutes.

A propolis-impregnated cellulose biomembrane produced from bacteria of the genus Komagataeibacter by Apis FloraLÉO RAMOS CHAVES

Technologically enhanced honey and propolis products

Honey and propolis are the two main raw materials used at Apis Flora, a company founded in 1982 in Ribeirão Preto. The company produces more than 100 pharmaceutical ingredients and medicine and food products distributed to more than 6,000 points of sale. In the mid-1990s, the company began investing in the development of technologically value-added products and collaborating with universities to produce more sophisticated medicines from honey and propolis. Among its newly developed products were high-concentration propolis microparticles produced by converting liquid propolis into a dry powder retaining the same pharmacological properties as the initial product. The company filed a patent with the Brazilian National Intellectual Property Institute (INPI) and currently exports about 18 tons per year to China (see Pesquisa Fapesp, issue No. 241).

Since 2011, Apis Flora has received PIPE funding for seven research projects. Two of these projects involved the development of biobandages made using propolis-impregnated cellulose biomembranes produced from bacteria of the genus Komagataeibacter. The biobandages are used to treat hard-to-heal wounds, burns, and chronic skin ulcers. The product has completed clinical trials in humans and is pending Brazilian Health Regulatory Agency (ANVISA) approval.

In another project, the company developed a mucoadhesive gel to treat the fungal infection vaginal candidiasis, in a collaboration with the University of São Paulo’s Ribeirão Preto School of Pharmaceutical Sciences (FCFRP-USP). “This product is currently being tested in a human clinical trial,” says Andresa Berretta, head of research, development, and innovation at Apis Flora. The company posted revenue of R$38.8 million in 2016. Out of its 103 employees and trainees, 13 are dedicated to research.

As research continued to build momentum, Berretta and co-researcher Franciane Marquele de Oliveira convinced Apis Flora’s owners to create Eleve, a startup dedicated to developing innovative drug delivery systems with expired patents. The new business is staffed by two researchers and three trainees and is being incubated within Apis Flora. Eleve has been awarded four PIPE projects since 2015. One is developing a nanotech formulation for an existing topical and oral drug against leishmaniasis. A second project is investigating a three-dimensional human skin model for testing cosmetic and anti-aging formulations.

Republish