It is unavoidable… the tires of agricultural machines leave tracks when they work in fields. In addition to the marks on the ground, the weight of tractors, combine harvesters, and other vehicles compact the soil. This is an old problem that, in today’s world of precision agriculture and high productivity, needs to be minimized to improve land use. Due to the demand from producers and agricultural machinery manufacturers, Pirelli decided to tackle the problem. After studies in partnership with the University of Campinas (Unicamp), it has formulated a new line of agricultural tires that ensure a better distribution of stresses in the soil and reduce compaction. The challenge began at the Center for Research and Development in Santo André, in the São Paulo Metropolitan Region, where, under the direction of engineer Argemiro Costa, Latin America Research and Development (R&D) Manager, the company realized there was a need to better understand soil so that the company could develop new agricultural tires.

“Soil modeling is not one of Pirelli’s strengths. We took advantage of a partnership we have had with Unicamp for 15 years and contacted Feagri (The School of Agricultural Engineering) and FEM (The School of Mechanical Engineering) to obtain more information on the subject,” says Costa. The studies began in 2008 and two fourth-year university students, Luis Alfredo Barbosa, at Feagri, and Thiago Henrique Rodrigues, at FEM, received scholarships from the company through the start of their master’s degrees, for a year and a half. “The company came to us with questions about the interaction between the tire and the ground and the resulting soil compaction. Then we proposed to carry out experiments in a box filled with soil in our laboratory,” says Professor Paul Graziano, at Feagri.

“Soil compaction is a serious problem due to the high level of mechanization. Currently, the problem is more severe in sugarcane plantations, where machines are very heavy, weighing 20 metric tons or more,” says Graziano. “Since we need to pass through a 0.8 m space between each row, with rows spaced 1.5 m apart, about 60% of the ground area is compacted by the tires or conveyor belts of harvesting or transport equipment. In this planting configuration, 32 tires pass over the soil during the sugarcane production cycle. One of the vehicles used for this crop is a sort of open wagon pulled by tractors, which really affects the soil. They work next to the harvesters to remove and transport the material harvested to the overflow yard, where the sugarcane is cut and transported to factories in trucks. “Each loaded wagon can weigh more than 15 t, and normally a tractor pulls two of them,” says Graziano. He explains that soil compaction reduces open spaces and hinders the movement of air and water in the soil that is required for optimal plant growth. Without these favorable conditions, productivity decreases.

FEAGRI-FEM / UNICAMP

FEAGRI-FEM / UNICAMP

“We performed some experiments with some tires that showed soil deformation, the level of soil compaction and even at what depth changes occur. We also noted in which region of the tire the effect is most prominent,” says Graziano. The experiments were conducted in a box filled with soil at the Unicamp Laboratory of Agricultural Machinery and Precision Agriculture. It is built of bricks and cement and is 12 m long, 2 m wide and 1.5 m deep. A steel frame passes above it, with various types of equipment both to prepare the soil in the box and to move the tire and exert the pressure necessary for the tests. The box was prepared with medium-textured soil, based on the Brazilian Soil Classification System, following a methodology developed by the laboratory. The tire was mounted on the steel structure and two load levels were applied, corresponding to 55% and 100% of the capacity of the agricultural tire model Pirelli used in the experiment.

Digital resources

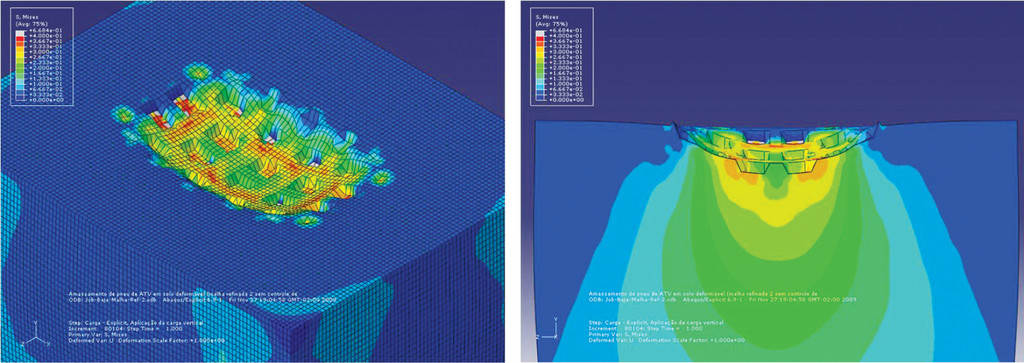

Tests were carried out with both stationary and moving tires, observing the vertical and lateral deformations of the tire and the ground with the help of instruments and sensors installed in the box used for the experiments. The Feagri Soil Laboratory also performed a laboratory analysis to obtain the parameters of the soil used. The entire contact area was measured using digital graphics resources. After the data was analyzed, it was transferred to the team at the School of Mechanical Engineering, led by Professor Euclides Mesquita Neto, and served as the initial parameters for the characterization of the computational model. Using mathematical modeling, they recreated the interaction between the tire and the ground, indicating the regions where compression and extension of depth occurred. Two associations were made, compaction and soil movement. “When the tire initiates contact with the ground, the treads or knobs move the earth, but do not compact it; it is only after this movement that compaction occurs,” says engineer Igor Zucato, head of agricultural product development at Pirelli. He explains that the manufacture of a new tire requires a number of parameters. “The curvatures are very complex, and the tread angles can be larger or smaller, longitudinal or transverse. In addition, agricultural tires must not skate around too much. They need excellent traction, and are produced with rubber compounds that are very resistant to laceration and cutting, as they are used in environments with many stones and cut stems that can puncture tires,” says Zucato.

PirelliIn red, the deepest marks in the ground.Pirelli

“Before the test, we thought that increasing the area of contact between the tire and the ground would reduce compression, which was not demonstrated to be true.” The important parameters are the distribution of weight and the angle, depth, spacing and number of treads, and if they should be different for different equipment models. “This data will determine the tire’s interaction with the ground,” says Zucato. To develop new tires, the company uses computer simulations, often running on supercomputers, before making the first prototype. “We have been using mathematical models for 25 years with the aid of off-the-shelf software and programs developed by us here in Brazil or at the company’s headquarters in Milan, Italy,” says Costa.

Pirelli’s Brazilian R&D center is the second largest of eight in the world, second only to the Italian center. “We carry out research on agricultural tires only in Brazil, where we develop products for the entire world,” explains Zucato. With a strong agricultural market, in 2012 Brazil manufactured 807,000 tires for this type of use, which represents just over 1% of all tires manufactured in the country according to the National Association for the Tire Industry (Anip). This was an increase of 1.6% compared to the previous year. In the computational experiments, Pirelli subjects the tires to all kinds of loads for different designs and features. Now knowledge of soil has been incorporated. “The partnership with Unicamp resulted in new knowledge that has already been incorporated into several products. Not just in one tire,” says Zucato. The two Unicamp students Pirelli hired to participate in the project made great contributions. “Luis Alfredo, who worked with the box of soil, provided us with a lot of information, especially on the interaction and behavior of the soil,” he says. Alfredo spent two years at Pirelli and then chose to begin a PhD and work at the Brazilian Bioethanol Science and Technology Laboratory (CTBE), also in Campinas.

Eduardo CesarOn the next page, a tractor pulls overflow wagons on a sugarcane plantationEduardo Cesar

Traction Performance

With the new data, Pirelli has developed a line of tires that already has knowledge of soil built in. One of them, the first to be released, is already being used on sugarcane overflow wagons. “Its tread pattern, type of curvature and number of treads are different from the configuration used before the study. The new tire has better traction performance compared to the previous models, and has a high cleaning rate,” says Zucato. Cleaning refers to the lack of accumulation of dirt and stones between the tire treads. “We call this line of low compaction tires high flotation because they distribute weight better. We are now preparing to launch a new line of agricultural tires that will also have the added soil compression knowledge built in.”

Thus, Pirelli’s partnership with Unicamp has resulted in many benefits. “In this type of study everyone wins, because we have obtained knowledge that we didn’t have and we believe that the university gained greater depth of knowledge in the area known as terramechanics, which studies the relationship between terrain and vehicles. We also released all the data for use by other studies or companies, within the spirit of open innovation. Petrobras, for example, could benefit because contact between submarine cables and the seabed is similar to interaction with the soil,” says Costa. Prof. Paulo Graziano is preparing a scientific article to be published in a specialized periodical.

Republish