When Bahian engineer and physicist José Walter Bautista Vidal (1934–2013) went out in search of people capable of implementing an ambitious technological development program devised by the Brazilian government in 1978, engineer Daltro Garcia Pinatti (1940–2021) seemed like the right person for the job. He was a professor at the University of São Paulo’s Institute of Physics (UNICAMP) and had been researching niobium, a malleable, shiny, and versatile metal, since 1973.

Between 1978 and 1991, the engineer spearheaded the Niobium Project, the aim of which was to develop national technology for producing niobium. The endeavor required millions of dollars from the federal government and private companies, and it employed more than a hundred researchers and technicians who gathered in a warehouse in the Lorena industrial park, in central São Paulo. Little known even among specialists, the project helped form the Lorena School of Engineering (EEL), which is now one of the University of São Paulo’s (USP) units. In August, it celebrated the 45th anniversary of the start of this adventure.

Collection of the Materials Engineering Department / EEL / USP

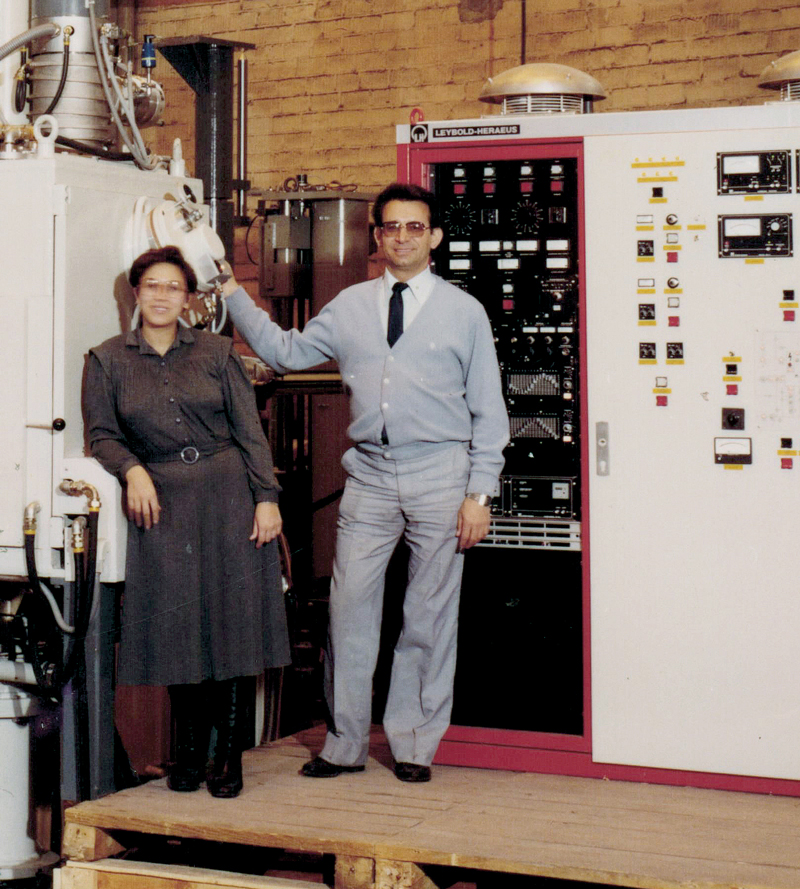

Rosa Conte and Pinatti with an electron beam melting furnace, in 1980, during a visit to the Leybold-Heraeus company, in Hanau, GermanyCollection of the Materials Engineering Department / EEL / USPThe work helped Companhia Brasileira de Metalurgia e Mineração (Brazilian Metallurgy and Mining Company—CBMM), the company that controls the world’s largest niobium deposits in Araxá, Minas Gerais State, to master the technology for producing niobium, used to manufacture superconducting wires for tomographs, magnetic resonance devices, and other applications. “Our mission was to develop a pilot plant and share the technology with the industry,” says physicist Rosa Ana Conte, who was an undergraduate and graduate student under Pinatti at UNICAMP, who participated in the Niobium Project from the start, and who now teaches in Lorena. “We did our part.”

Pinatti graduated from the São Carlos School of Engineering (EESC) at USP in 1964 and completed his Master’s and Doctorate at Rice University, in Texas, USA, in the late 1960s. His education was critical to the Niobium Project’s success. At Rice, he had an electron beam melting furnace at his disposal for researching the properties of molybdenum and alloys for high-temperature applications.

The equipment was used to refine the metal and obtain samples with a high degree of purity, which increased the material’s resistance and its usefulness for special applications, such as the heat shield for the spacecraft developed by the US space program for the first crewed mission to the Moon. In Brazil, Pinatti convinced UNICAMP to buy a similar furnace for his laboratory at the Institute of Physics, imported from the German manufacturer Leybold-Heraeus, for special metals research.

The equipment arrived in 1974 and Pinatti used it to develop a new process for refining niobium, applying the knowledge gained from his molybdenum experiments. Until then, the traditional method for producing materials such as niobium involved very expensive chemical processes. With the German furnace, Pinatti adopted a physical process in which the high temperatures generated by the electron beams inside the machine produced a similar effect, but at a much lower cost.

Léo Ramos Chaves / Revista Pesquisa Fapesp

Forty-five years later, some of the researchers and technicians who participated in the Niobium Project: Sebastião Ribeiro, Rodolfo José Lopes, Rosa Conte, Carlos Roberto Dainesi, and Antonio Sartori (from left to right)Léo Ramos Chaves / Revista Pesquisa FapespSquandering wealth

It took the researcher several years to develop the technology and achieve the first results at the UNICAMP laboratory, but it wasn’t long before his path crossed that of Bautista Vidal. Secretary of Industrial Technology for the Ministry of Industry and Commerce under General Ernesto Geisel (1974–1978), the Bahian physicist coordinated initiatives to reduce Brazil’s dependence on imported oil, to acquire technology that the country had not mastered, and to seek autonomy in areas considered strategic.

When it came to niobium, Pinatti and Bautista Vidal shared the opinion that Brazil was making poor use of its economic reserves, limiting itself to exporting raw ore extracted from the earth instead of products that would add value to the metal and create niche markets. “Basically, we were exporting earth containing niobium, and that didn’t make sense,” explains physicist Antonio Fernando Sartori, another former student who worked with Pinatti at UNICAMP and in Lorena, and who continued teaching at EEL after the project ended. “We were squandering the wealth we had.”

Pinatti’s team at UNICAMP managed to produce several samples in the form of small ingots, solid cylinders 25 centimeters (cm) long, 5 cm in diameter, and 4.2 kilograms (kg) in weight. In 1978, Bautista Vidal brought the material to Germany to undergo quality testing. The analyses proved that the samples produced by the Brazilian scientists were highly pure and convinced the Germans to sign a cooperation agreement with Vidal’s office to develop the technology on a pilot scale.

Léo Ramos Chaves / Revista Pesquisa Fapesp

Electron beam melting furnace used in the 1980s and 1990s in LorenaLéo Ramos Chaves / Revista Pesquisa FapespPinatti was going to need a bigger furnace, a suitable site to install it, and money to hire researchers and technicians and to fund their work. Their solution was to classify the project under the umbrella of a private foundation, which could receive public and corporate funding and would have the flexibility needed to make the venture viable, without the constraints of federal bureaucracy. To speed up the process, the Ministry of Industry and Commerce assumed control of the municipal foundation that ran the Lorena School of Chemical Engineering, which was struggling financially, renaming it the Industrial Technology Foundation (FTI), in 1978.

Bautista Vidal employed a similar approach for other projects. The program that received the most funding was Proálcool, which encouraged the production of alcohol fuel and the development of new car engines. “Technology is power,” said the Bahian physicist in 1996, in a statement to researchers at the Center for Research and Documentation on Contemporary Brazilian History (CPDOC), of the Getulio Vargas Foundation (FGV). “When I took over, I occupied two rooms next to the Minister’s office. When I left, [the Secretariat] was housed in a 12-story building.”

The Peixoto de Castro group, which manufactures steel pipes in Lorena and has businesses in the chemical industry, donated the land and supplied metal structures to support the Niobium Project’s facilities. Companhia Siderúrgica Nacional (National Steel Company) and Companhia Ferro e Aço de Vitória (Vitória Iron and Steel Company), which were state-owned companies at the time, donated some of the steel used for construction. Construction was completed just one year after the arrival of the new furnace, built by Leybold-Heraeus according to Pinatti’s instructions. The equipment cost approximately US$1 million, equivalent to US$3.5 million today, according to engineer Carlos Alberto Baldan, who ran FTI and worked with Pinatti since the project’s inception until 2018.

Simone Colombo/EEL/USP

In 2008, The EEL’s Materials Engineering Department honored PinattiSimone Colombo/EEL/USPThe furnace’s two electron cannons had a power of 300 kilowatts, consuming energy equivalent to that needed to run 100 electric showers simultaneously. A vacuum pump capable of extracting 18,000 liters of air per second from inside the furnace ensured the right environment for purifying the metal. A cooling tower was built alongside the warehouse to ensure a sufficient volume of water to cool the material produced by the machine. The equipment manufactured larger ingots, 1.2 meters (m) in length, up to 13 cm in diameter, and 136 km in weight, and had the capacity to refine 20 tons of metal a year.

CBMM was the Lorena project’s biggest client. Founded by the Moreira Salles family in 1955, the company invested at least US$3.5 million in projects developed by FTI in the 1980s, according to a company report kept at the National Archive, or nearly US$10 million at current values. In addition to niobium refining services, their contracts included training for company employees and technical assistance for five years after CBMM acquired its own furnace. In exchange, the foundation would receive 1% of the revenue from ingots produced on an industrial scale.

The federal funds that financed the Niobium Project ran out during the country’s economic crisis in the 1980s, and the precarious institutional arrangement that sustained the FTI began to attract the attention of the Federal Court of Auditors at the end of the military regime, in 1985. The flow of funds stopped in 1990, the municipal foundation was abolished, and the São Paulo state government ended up absorbing the engineering school the following year, paving the way for its incorporation into USP. “We spent five months in limbo, without pay, until a solution was found,” recalls physicist Conte.

Léo Ramos Chaves / Revista Pesquisa Fapesp

Warehouse that houses machinery and equipment used to produce niobiumLéo Ramos Chaves / Revista Pesquisa FapespThe final CBMM contract with Lorena researchers expired in 1995, without renewal. Pinatti’s furnace continued operating for some time after the Niobium Project, fulfilling orders from industries and research institutes until it was shut down in the early 2000s. The equipment is still installed in the warehouse, but there is no way of getting it up and running without replacing the electronic control system and reconnecting the high-voltage lines. “It has become outdated,” says Rodolfo José Lopes, a technician at the school who has maintained the furnace since its arrival.

Much of the paperwork documenting the project disappeared along with the Lorena researchers’ departure. The school’s Materials Engineering Department has old papers and photographs but has been unable to organize the material properly. Last year, when USP began the process of selecting projects to preserve its units’ historical collections, veterans of the Niobium Project asked for funds to salvage remnants of the venture’s history and create a memorial in the Lorena warehouse, but the request was not approved.

CBMM went ahead with its own project and, last year, brought in a revenue of R$11 billion, profiting R$4.5 billion. Most of its revenue comes from exporting ferroniobium, an alloy used by steel mills to make stronger steels. Its industrial plant has the capacity to produce 270 tons of niobium per year, but sales of special products like this account for less than a tenth of the total revenue. The Moreira Salles family, who are also Itaú Unibanco shareholders, are still in charge of the business, and now have Japanese, Korean, and Chinese companies as partners. They are organized in two consortia, each with 15% of the shares.

The company plans to invest R$300 million in research and development, equivalent to 3% of its revenue. There are more than two hundred projects underway, most of them in partnership with institutions and universities in Brazil and abroad. The main objective today is to use niobium to develop more efficient lithium batteries for electric cars. There are no EEL-USP projects currently underway. On CBMM’s website, there is no acknowledgment of the contribution that Lorena’s researchers made to the company.

Scientific articles

MARCOMINI, J. B. & CONTE, R. A. Refino em forno de feixe de elétrons. Revista ABM Metalurgia, Materiais & Mineração. Vol. 71 March/April 2015, pp. 156–9.

CASTRO, M. H. M. & SCHWARTZMAN, S. Tecnologia para a indústria: A história do Instituto Nacional de Tecnologia. Rio de Janeiro: Centro Edelstein de Pesquisas Sociais. 2008.

SARMENTO, C. E. B. Ciência, indústria e soberania nacional: As transformações na política tecnológica brasileira na década de 1,970 – Memória e projeto. Revista História Oral. Vol. 2, June 1999. pp. 153–66.

Report

“CBMM – 30 anos no desenvolvimento tecnológico do nióbio”. Report submitted by the company to the National Security Council on September 23, 1986. National Archive. Fundo do Conselho de Segurança Nacional, BR DFANBSB N8.0.PSN, AIC.102, pp. 187-96.