Better known as Thoroh, a childhood nickname he later adopted as his stage and professional name, physicist Eunézio de Souza responds with the same level of enthusiasm to a block of graphene foam—so light that it rests imperceptibly on his palm—as he does to posters for his recitals and opera performances as a professional singer.

On the afternoon of September 13, he took the Pesquisa FAPESP team on a tour of the laboratories at the Advanced Graphene, Nanomaterials & Nanotechnologies Research Center (MackGraphe) at Mackenzie Presbyterian University, created by him in 2013 to develop research and products using graphene, which is formed by a single layer of carbon and is stronger than steel. At the time, he invited journalists to walk down the building’s staircase and, to demonstrate the acoustics, he took a deep breath and proceeded to sing an excerpt from the “Soave sia il vento” trio, from the opera Così fan tutte, by Austrian composer Wolfgang Amadeus Mozart (1756–1791). “I cannot choose between physics and music,” he says. “I need both to live.”

Married to Elisabeth Ratzersdorf, an opera singer at the São Paulo Municipal Theater, and with three teenage children, Thoroh’s voice became even more powerful last June, after he took over leadership of the nanotechnology department at the Federation of Industries of the State of São Paulo (FIESP). One of his goals is to warn entrepreneurs: “We need to act while there is still time. A tsunami is coming. China has at least 500 companies in the graphene market.”

Specialty

Materials physics and photonics

Institution

Mackenzie Presbyterian University

Education

São Carlos Institute of Physics and Chemistry at USP (1996), PhD from the Gleb Wataghin Physics Institute at UNICAMP (1991)

Scientific production

50 scientific articles

Why is graphene so successful?

Because of its superlative properties. A box holding 1 cubic meter (m3) of water weighs 1 ton; 1 m3 of air weighs 1.3 kilograms. The same volume of graphene aerogel weighs 160 grams. Graphene is seven times lighter than air and 200 times stronger than steel. A graphene sheet is nearly transparent. The glass in a window lets 92% of light through; graphene, on the other hand, lets 98% of light through. As it is virtually impermeable, it can act as a barrier against corrosion. It is also possible to drill holes into the structure to produce membranes that act as filters, letting through only specific substances.

Russian physicist Konstantin Novoselov, one of the winners of Nobel Prize for the discovery of graphene, said in an interview with Folha de S. Paulo that he had no idea it would have any uses.

That’s right. When graphene was discovered in 2004, we had no idea what to do with it. At the University of Manchester, in England, Kostya [Novoselov] and [Andre] Geim used adhesive tape to obtain graphene, sticking the tape to and pulling it from a graphite sample successively until they obtained a single layer of atoms from the sample. No one could believe it. Their article in Science in 2004 described the crystal, but no one had measured the parameters of this kind of material. Its conductivity was much higher than that of copper. Possible uses for graphene gradually appeared: it can be incorporated into other materials, making plastic and tires much stronger, and because it can conduct electricity, it can turn plastic into a conductor as well.

How did graphene motivate the construction of MackGraphe?

The research center is the result of a partnership with Antônio Hélio de Castro Neto, director of the Graphene Research Centre at the National University of Singapore. We went to graduate school together at UNICAMP [University of Campinas]. He got into graphene in 2005, when I was working with photonics [the study of the generation, emission, and transmission of light]. In July 2010, he predicted that Geim and Kostya would win the Nobel Prize. Many people were already working with this material, but there were few people in photonics. In October of that year, they really did win the Nobel Prize, and we started writing a research project. I have been here since 2003, after seven years with the University of Brasília. I created an internationally renowned study group on photonics, and we coordinated the physical part of FAPESP’s Kyatera project in the state of São Paulo. We were two photonics professors—Christiano de Matos and myself—and graphene represented an opportunity to do something different. Our first funding request to FAPESP, as a regular project, was declined, but one of the reviewers suggested that we request a Thematic Project instead—a broader research grant mechanism that would allow a larger investment by the Foundation.

Léo Ramos Chaves

Graphene aerogel (foam), lighter than airLéo Ramos ChavesHow did you present the idea to the Office of the Dean at Mackenzie University?

For the Thematic Project, we would need to establish a collaboration between the Graphene Research Centre in Singapore and Mackenzie University. In August 2011, I presented to the Office of the Dean a project for the creation of a graphene research center that would bring together the areas of photonics, electrical and materials engineering, and chemistry. As a reference, I had conversations with my colleagues Pierre Kaufmann [1938–2017] and Adriana Valio of the Mackenzie Center for Radio Astronomy and Astrophysics. The dean loved it, but he had no idea how big it would become. There was no talk yet of constructing this building. I asked for an area of 60 square meters [m2] for a lab; that then changed to 100 m2, and I knew I would need even more. Today, we have 5,400 m2, nine floors, and a staff of 100 people.

Where did the money to fund all this come from?

In December 2011, I realized it was the 20th anniversary of my obtaining my PhD. I messaged Carlos Henrique de Brito Cruz [scientific director of FAPESP], who had been my advisor, and asked if he wanted to celebrate. He said yes. I also invited the entire examining board: Nilson Dias, who was superintendent of IPEN [Institute of Energy and Nuclear Research], Sérgio Celaschi [from the Center for Telecommunications Research and Development—CPqD], Hugo Fragnito [then with UNICAMP; currently a collaborating researcher at MackGraphe]. We all agreed to meet at a wine bar nearby. I also invited the dean of Mackenzie University, Benedito Aguiar. During dinner, I mentioned my work with graphene, working with Antônio Hélio, which interested Brito. He had no idea that FAPESP had turned down the first project. He proposed that we participate in a pilot program called SPEC [São Paulo Excellence Chair]. In January, the dean and I went to Singapore, signed the agreement, and he began to realize that the project was becoming much larger than he had anticipated. SPEC allowed Antônio Hélio to participate much more actively in the project because the university would be able to pay him to be here three months out of the year. The project went through four international reviewers: they all gave it an excellent rating. Two of them even said we were promising too much.

What were you promising?

We quantified how many articles we wanted to publish in high-impact journals, how many postdoctoral, doctoral, master’s, and undergraduate students we wanted to teach, and how many startups and spinoffs we wanted to create. When FAPESP gave us their answer, Brito wrote a letter stating that it was a very large investment—something close to R$15 million today. The project was approved on merit, but a financial contribution from the institution was necessary to move ahead. At a meeting at FAPESP, it was agreed that Mackenzie University’s board of directors would present a document identifying their financial contribution. The finance committee asked me what needed to be done. I said: “A research center.” For financial support to mean anything, we could not invest one real less than FAPESP. They agreed—and two months later, in December 2012, demolition began on the building that used to be here. The research center opened in March 2016, and I am grateful to the institute for their continued support ever since.

How do you explain this interest on the part of the university?

The research center was an opportunity for the institution to regain prestige—which it had plenty of in the past. For example, until the 1960s, an engineering degree from here was valid in the United States. The greatest challenge was managing time and preparing the team. Before the project was approved, I sent technicians, students, and professors to be trained in Singapore. We had the support of many colleagues: Sergio Rezende and Anderson Gomes [Federal University of Pernambuco], Marcos Pimenta [Federal University of Minas Gerais, UFMG], Fragnito, Brito, Amir Caldeira [UNICAMP], Henrique Toma and Lucio Angnes [University of São Paulo, USP], José Roque da Silva and Harry Westfalt [National Synchrotron Light Laboratory], and José Bressian [IPEN], not to mention Antônio Hélio from Singapore. I went to Manchester, where I met Kostya for the first time and met Andre again. Nearly all of them came here to give seminars and helped design the research center, which was entirely inspired by Bell Labs, where I did a postdoctoral internship.

Personal archives

On a visit to Bell Labs, where Souza conducted postdoctoral research in 2019Personal archivesWhy did you adopt Bell Labs as a model for MackGraphe?

I wanted to create a research center where the training of professionals would be shaped by all areas—especially in such a multidisciplinary field as graphene. The project that we got approved was in the area of photonics—but in order for the research to achieve the standards we promised, it would be necessary to master the production and characterization processes of graphene. Aldo Zarbin, from the Federal University of Paraná, recommended one of the first professors we hired here, Sergio Domingues. We were able to hire younger people, such as Lúcia Saito and Cecília Silva, who still needed to get their postdoctoral degrees and gain experience. At a 2013 conference in Bilbao, Spain, there was a session on graphene centers. The Japanese showcased monumental research centers. China put us to shame with the vast amount of resources they had allocated to the area. Andrea Ferrari, from Cambridge, spoke of the world’s first published paper about carbon in the nineteenth century and concluded by saying that, for them, graphene was just another material. We didn’t have their money, let alone their heritage. I went to the back of the room and rewrote my entire presentation.

And what did you say?

Our one distinction is the model we follow. Our research center follows the Bell Labs model. I showed them this TRL [Technology Readiness Level] curve. TRLs range from 1 to 9. Levels 1 to 3 refer to basic research; levels 3 to 5 are applied research; levels 5 to 6 are development; and levels 7 to 9 refer to market use. Universities usually go up to 3. Our mission at MackGraphe is to convert scientific knowledge into wealth for society at levels ranging from 1 to 5. The core of TRL is development-centered; it’s what we call the valley of death, where resources run out and ideas die. The mission of our research center is to reduce the valley of death. We want to get as close to development as possible, and this is what makes us different from other research centers. This approach has to do with my experience in the United States.

What did you learn at Bell Labs?

Everything I know. It used to be the mecca of solid-state physics. It’s where the transistor, the mobile phone, satellite communication, the laser, and the solar cell were all invented. In three years, I worked with fiber optic lasers, solid-state lasers, and something called SEED—self-electro-optic effect device. I built artificial retinas. Bell Labs had one principle: “keep it simple.” You have to strive to be the best in the world, no matter what. Interestingly, the principles of the education my mother gave me were very similar: study, work hard, believe in yourself. In the United States, I never looked down on myself. I just didn’t know who I really was.

What do you mean?

I had no idea how good my work and training had been. I arrived on a Saturday. On Sunday, Mohammed Islam, who would be my boss and who is now with the University of Michigan, asked me, “Do you want to visit Bell Labs today?” I was impressed with its structure. He turned on a laser to show me. It was a fiber optic laser; I had already put together several of those. When he looked at the light pulse on the device, he didn’t seem pleased, so I asked if I could tinker with it. I was able to adjust it in 20 minutes, lowering the pulse frequency from 1,600 femtoseconds to 250 femtoseconds [each femtosecond is equivalent to 10-15 seconds]. He said, “I’ve been trying to do that for three months.” The next day, he invited Roger Stolen, Linn Mollenauer, David Miller, and the legendary James Gordon [1928–2013], authors of articles that taught me everything I knew, to have lunch with me; I couldn’t bring myself to say a single word. I returned there last January with my three children and showed them the Holmdel facilities and the restaurant I used to frequent, the Jerusalem Pizza. The owner still remembered me; I was the only black man that frequented the place.

Léo Ramos Chaves

In a 1,000ºC oven, carbon atoms from graphene crystals on a copper foilLéo Ramos ChavesWhat are the great works of MackGraphe?

There is the most talked about and most important work. Graphene is the best two-dimensional material, but there are over a thousand. Here, we work with about 10 or 12, one of which is black phosphorus. In 2016, we demonstrated that the properties of black phosphorus could vary according to the movements of the atomic structure. It has been our most cited work so far. Because as a scientist I value practical application, I believe the most important research is on graphene in the production of short-pulse lasers; in this field, our group is at the forefront worldwide. The lasers are ready to enter the development phase; we now need to develop a prototype, write a business plan, and introduce it to the world. The success of this research center will be measured by the sale of products that have somehow resulted from the research done here.

How are relationships with business going?

They are challenging, but should improve. In June, some people from FIESP were at Queen Elizabeth’s birthday party at the British Consulate. I attended too, and one of the directors, Eduardo Giacomazzi, asked me to direct the nanotechnology department. The first event we organized was a nanotechnology forum, with Kostya, last September. My next mission is to map nanotechnology companies, which are spread across multiple industries, and bring them closer to university institutions to improve the process of converting research into emerging technology products.

How were you received at FIESP?

The only reason I’m with FIESP is the fact that I have owned a nanotechnology company for over a year. I created it after coordinating a debate at a forum in China with other international participants in September 2018. The goal was to analyze the situation of graphene companies in China. There were 5,000 listed in three areas: those that produce graphene, those that produce equipment for the graphene sector, and those that develop applications for graphene. Most were ineffective: they had no employees, no address, and no product. Out of those 5,000, only 20% were really consistent. Let’s assume that only 10% of companies are worthwhile: Then we are talking about 500 companies. Do you have any idea how many researchers work with graphene in Brazil, including undergraduate students? Less than 500. When I saw this, I called a FIESP vice president and friend of mine, Rafael Cervone Netto, and told him a tsunami was coming from China and that FIESP needed to do something. He spoke with another vice president, José Ricardo Roriz, and we organized a closed seminar with Geim for about 10 entrepreneurs invited by FIESP. We have to react while there is still time. The issue is that Brazil is used to chasing technological revolutions, but not to being in or near their center. There is less risk in buying something that has already been tested, but the price is higher, and leadership is out of reach. China threw piles of money into developing the graphene industry; now, it’s in the lead.

Léo Ramos Chaves

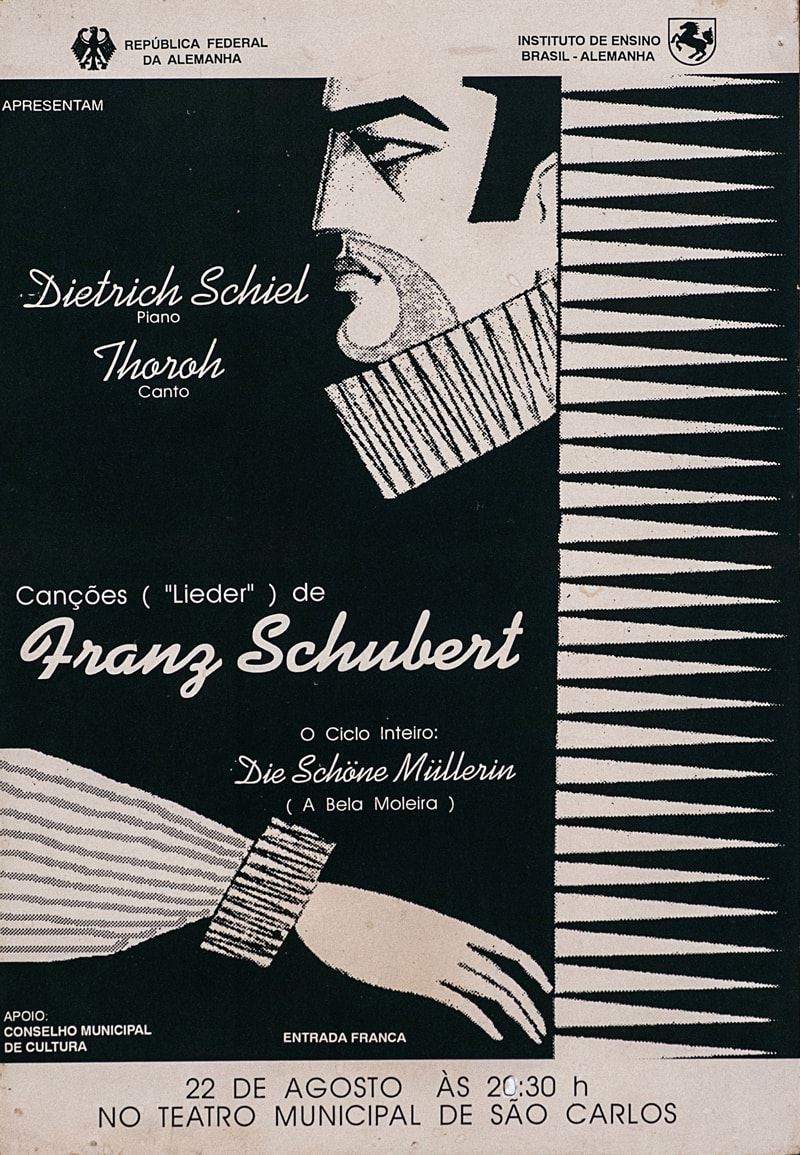

Parallel to his career in Physics, Souza performs in recitals and operas as an opera singerLéo Ramos ChavesAre there no companies producing graphene in Brazil?

Very few. At a conference in Rio de Janeiro the other day, some companies from Minas Gerais showed up. There are two projects there: MG Grafeno, by CODEMIG [Economic Development Company of Minas Gerais], which is able to produce 100 kilograms (kg) of graphene per year, and CTNano [Center for Nanomaterials and Graphene Technology], at UFMG, which began before our research center and recently inaugurated its own building, with money from Petrobras and BNDES [Brazilian Development Bank]. Undoubtedly, the UFMG group, led by Marcos Pimenta, produces the best science in graphene and carbon nanomaterials in Brazil. We’ve found a loophole here and have been exploiting it. Without basic research, we will not be able to train people to turn ideas into products. There may be some industries that don’t require basic research, because someone has already done it and it’s possible to buy, but that model cannot be replicated.

It’s been six years since you created the research center. Have you been able to deliver what you promised?

We’ve published almost three times more scientific articles than we had promised, in journals with an average impact factor of around 6. We trained 112 people instead of 90. However, we did not reach the projected number of PhD graduates: we promised 10 and only eight graduated. We’ve created two startups, Autoscience Technologies and Nano Up, which are located on the sixth floor, which is dedicated to new companies. Most of the rooms are still empty.

Do you produce graphene?

Of course! We became self-sufficient after the project’s first phase, during which we first brought samples from Singapore and learned how to make it; then in the second phase, when we had already learned the process, we began exchanging samples with them. We can produce graphene using adhesive tape, as Geim and Kostya did, through liquid and chemical exfoliation of graphite, or by artificially growing crystals on a copper surface.

What is your view on minority policies and affirmative action at universities?

I shouldn’t be taken as an example because even though I come from a black family, we have always been community leaders. My father was in the railway business and was very influential in my hometown, Bom Jesus do Galho, in Minas Gerais—whose population is around 6,000. I had an excellent education. Neither I nor anyone in my family have any remaining baggage regarding slavery or an inferiority complex. But when I look at Brazil and the rest of the world, I notice that minority policies are still necessary—and they are temporary: the children of those benefitted by such policies already have access to a different education and no longer need them. If you walk down the street at night and see two white men and two black men, it’s the two black men you’ll fear most—even I would fear the black men in that scenario, despite being black myself, because statistics crystallize negative images associated with either group. We are stigmatized. And there is only one way to change that: studying more and working to increase the economic power of black people. In one or two generations, we will have a fairer distribution of income.

Have you ever faced discrimination yourself?

Never in other countries, but here I have. In 2002, as I was returning from a trip to the United States as a visiting professor in Rochester, my wife picked me up at the airport, and we went to lunch together. We went into the restaurant, and a man at another table kept looking at me strangely, as though I wasn’t supposed to be there. I took a couple of steps back and asked him, “Are you alright? Do you know me?” He was alarmed; he wasn’t expecting it, because most of them are cowards—and I, being so large and having such a booming voice… He cowered. Brazilian universities are not racist, but sometimes there are people who cannot accept that someone like me has achieved what I have.

How do you reconcile physics and your music career?

I divide my time as best I can. Music has been a part of my life since I went to Escola Técnica Federal de Ouro Preto [Ouro Preto Federal Technical School]. I was a troubled teenager. My voice was very deep; everyone could sing popular music except me. I could only sing songs by Nelson Gonçalves [1919–1998], who also had a deep voice. There was a soap opera being aired at the time called Cabocla, which featured a song of his. I was singing, “Cabocla, seu olhar está me dizendo…” in my dormitory when the opera singer Amin Feres [1934–2006], the most well-known bass in Brazil, who was walking down the street outside, heard me. He came in and asked me to sing in his choir, which was at my school, but I had no idea. There, I discovered songs specifically written for my voice. It was wonderful. I joined the choir and became a soloist. Two years later, I got a scholarship to study voice in Karlsruhe, Germany—but I didn’t go, because I thought having a career in music was outside of my reality. Many years later, at Bell Labs, I had a chance to audition at the Metropolitan, thanks to my voice coach, Jerome Hines [1921–2003]. Again I didn’t go. Having two professions was very difficult in the United States. I can’t choose between physics and music. I need both to live. When my parents separated and my family’s situation deteriorated, I made money as a musician to be able to study physics. I conducted the São Carlos USP choir and the Lápis John Faber choir, and I taught vocal technique for the UFSCar [Federal University of São Carlos] choir. Once a week, I went to UNICAMP to study voice under Niza de Castro Tank, the greatest opera singer in Brazil. When I went to graduate school at UNICAMP, I won a scholarship and got to conduct the choir at PUC [Pontifical Catholic University] Campinas. I have a singing career. I have sung a few operas with OSESP [São Paulo Symphony Orchestra], such as Carlos Gomes’s [1836–1896] O guarani, at the opening of the 1996 Winter Festival in Campos do Jordão. The last rehearsal attended by the great conductor Eleazar de Carvalho [1912–1996] was for this opera, and I was part of it. As I was singing O Dio degli Aimorè, he started feeling ill, interrupted the rehearsal, left, and never came back. The opera was then conducted by Diogo Pacheco. I slowed down a little because of the research center; my last concert was in Barcelona, in 2017. But I’ll have another one in November, with pianist José Mauro Peixoto, at the São Paulo Country Club, where I will get to sing with my wife, soprano Elisabeth Ratzersdorf. It is being organized by Russian violinist Svetlana Tereshkova.

See photographs of the graphene production process at http://bit.ly/g284Grafeno

Republish