Reduction of greenhouse gas (GG) emissions on offshore oil & gas platforms is a growing concern in the industry, and two ongoing research projects in Brazil may contribute to this goal. Petrobras and the Polytechnic School of the University of São Paulo (POLI-USP) are working on a floating wind-generation system to provide electrical energy to production units in the pre-salt region. The other initiative brings together the China National Offshore Oil Corporation (CNOOC) and the Alberto Luiz Coimbra Institute for Graduate Studies and Research in Engineering at the Federal University of Rio de Janeiro (COPPE-UFRJ). In August this year the two institutions partnered to develop offshore wind farms using hybrid renewable sources.

The maritime oil platforms traditionally receive their electrical power from diesel- or natural gas-driven generators. Brazilian pre-salt reserves are characterized by a composition of natural gas associated to oil, and platforms in this region use gas extracted on site to run their generators.

According to professor of ocean structures and subsurface marine engineering at COPPE Segen Estefen, the larger FPSO (Floating Production Storage and Offloading) platforms operating in pre-salt areas each require generators of 150-megawatt (MW) installed power. The energy generated on these platforms runs several exploration devices for production, oil and gas separation, injection of water, and reinjection of gas into the wells, along with accommodation for the operatives.

The ongoing project at POLI-USP anticipates the use of a floating wind-generation system on a base anchored to the ocean floor for direct supply to underwater systems or the FPSO itself, reducing GG emissions from natural-gas generators. “The idea is for the structure to be anchored at a safe distance from the platform, with the energy transferred via electrical cables known as umbilicals,” explains project coordinator Alexandre Simos, naval and ocean engineering professor at the POLI.

A safe distance is one that safeguards the platform from any adverse effects in the event of a damaged anchorage system or in the extreme situation of a wind turbine overturn. The rotor, normally comprising three blades and the central hub to which they are fixed, can reach up to 220 meters (m) in diameter, the equivalent of almost six Christ the Redeemer statues stacked upon one another. Much of the project engineering work involves preventing this type of occurrence.

The wind-generation technology is the same as that used by wind turbines installed on land, in this case fixed to the ocean floor in shallow waters or on floating platforms (see Pesquisa FAPESP issue nºs 275 and 290). Floating systems at sea, however, require studies into the most suitable type of platform and anchoring to support the wind turbines in all maritime and climate conditions, including the prevailing winds at each site. Advanced calculations also need to be carried out in terms of the stability and accelerations of the selected floating platform, considering several different combined wave, wind, and current conditions.

The USP and Petrobras project opted for a semisubmersible floating platform to support a 15-MW generator, on which small floating wind farms can be assembled, with capacity to service between 10% and 30% of the energy requirements of an FPSO, depending on its size. The structure is around 100 m in diameter, and comprises four cylindrical columns of naval steel, an alloy with anticorrosive characteristics and good weldability, with a draft (the submersed part) of less than 20 m. One of the columns forms the base of the wind turbine tower. A system of chains and steel cables connected to piles driven into the ocean floor keep the system anchored.

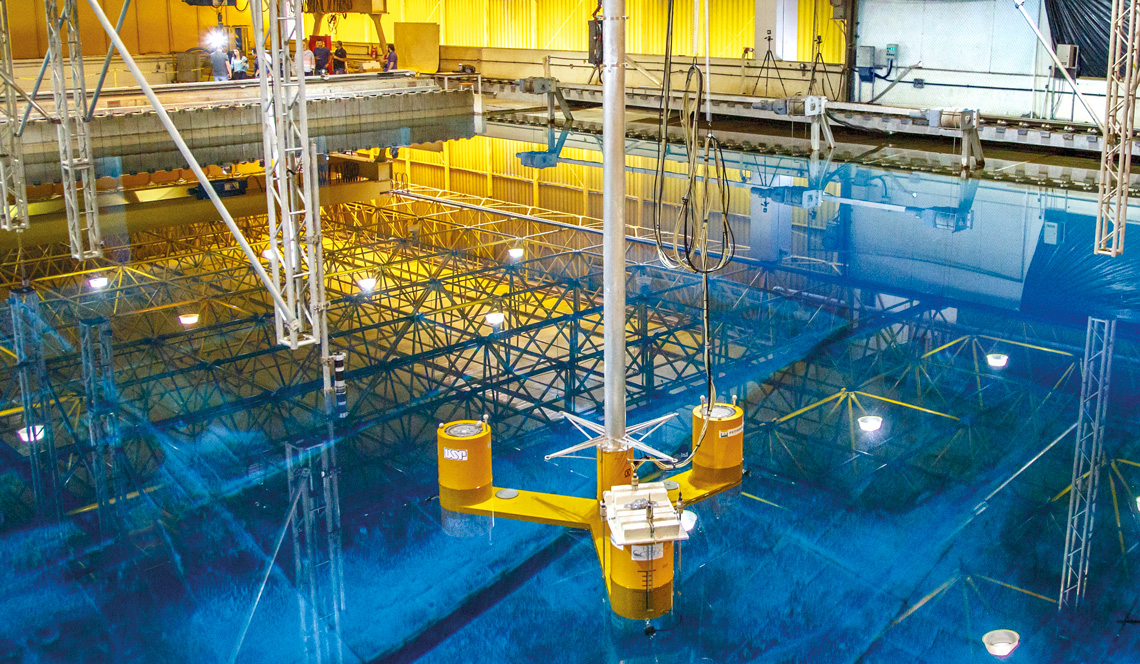

A reduced-scale version was tested in August at the COPPE Ocean Technology Laboratory (LABOCEANO), reproducing the harsh pre-salt conditions of the Santos bay, some 300 kilometers (km) offshore in an area where ocean depths exceed 2,000 meters. “This was the world’s first test of a wind-energy structure designed to operate in those conditions, and we can say that the technical results were positive,” says Simos. The experiment was groundbreaking in its use of wind energy to power a submerged system for injecting water into an oil well.

Naval engineer Kazuo Nishimoto, a professor at the Naval and Ocean Engineering Department of POLI-USP and scientific director of the Offshore Technology Innovation Center (OTIC), one of the Engineering Research Centers (CPE) supported by FAPESP and oil giant Shell, says that wind farms are among the most promising alternatives for electrical energy supplied to oil platforms on the high seas, but certain obstacles need to be overcome.

“We still face technical challenges to install, operate, and maintain these installations in deep waters, where they will be subjected to extreme wave, wind, and current regimes. New systems enabling installation and maintenance at an acceptable cost need to be designed and developed,” he goes on. “Moreover, renewable energy generation structures at sea, such as wind or solar systems, are still very expensive compared to conventional setups used today, which emit CO₂ [carbon dioxide]. The cost needs to come down to make them economically viable.” The Offshore Technology Innovation Center analyzes and integrates different decarbonization solutions for offshore operations.

The collaboration between the Chinese CNOOC and UFRJ involves two projects to be conducted by the Ocean Renewable Energy Group (GERO), an arm of the COPPE Underwater Technology Laboratory. One will look into which offshore wind platform technologies for depths of up to 150 m are most suitable for ocean and climate conditions and the prevailing winds of the Brazilian coastline.

The study also involves indication of the best concepts for producing the structures, adaptation of available inputs such as high-performing steel or concrete, and the logistics for towing the structure from the shipyard to the operating site. The researchers are also looking at procedures for maintenance and repair of offshore equipment.

The other project run by GERO is geared toward energy supply to oil & gas platforms in waters between 500 m and 2,500 m deep, employing the concept of hybrid plants with wind and solar generation, and using wave energy converters, which harness wave power to drive the turbine and generate electricity (see Pesquisa FAPESP issue nºs 113 and 290).

The idea is for each generator to have its own floating base, with the option to share the mooring systems if applicable. The potential advantages to be studied are the stability and safety that a mix of different sources can provide to the system. “One key challenge of deep-water facilities is the impact of giant waves on wind and solar facilities,” says Estefen.

The researchers are considering installing wave converters to protect the wind and solar generator sets which, besides generating energy, will act as a buffer, reducing the impact of upstream waves that form before making contact with the generators. “With greater stability, the wind generators gain in yield, and the solar equipment in durability,” explains the engineer.

Floating solar plants (see Pesquisa FAPESP issue nº 324) are currently only used in calm waters, so they will need to be tested and likely refined for use in more turbulent conditions. “We have two years of intensive work until the prototype test of the hybrid facility at LABOCEANO,” he concludes.

Equinor

Floating wind farm Hywind, off the Scottish coast: first commercial project installed at seaEquinorThe world’s first floating offshore wind farm has been operating for six years in Europe. Designed by Norwegian energy corporation Equinor, the facility was installed in the North Sea in 2017 and comprises five turbines less than 30 km off Peterhead, a town on the Scottish coast to where the generated energy is supplied.

This year, also in the North Sea, Equinor inaugurated the world’s biggest floating wind farm to provide electricity to oil & gas platforms. With 11 turbines and total installed capacity of 88 MW, it will provide 35% of the energy required by its five platforms in the area, preventing the emission of some 200,000 tons of GG annually.

The infrastructure is installed 140 km off the Norwegian coast at depths of up to 300 m, far shallower than the 2,000 m in the Brazilian pre-salt region. Both the pioneering Scottish structure and the more recently inaugurated one use spar-type floating bases, technology requiring nothing more than a vertical cylinder with a draft that can exceed 100 m, depending on the particularities of each facility.

Petrobras has lodged an environmental licensing application to install a floating wind farm in waters between 120 m and 160 m deep, 42 km off Cabo Frio on the Rio de Janeiro state coast. The application covers up to 178 wind turbines of 18 MW each. For now, Brazil neither has any legislation on maritime area usage rights for the generation of renewable energy, nor concession standards. Three law bills are under evaluation in the National Congress with an end to providing regulation.

Projects

1. OTIC – Offshore Technology Innovation Center (nº 22/03698-8); Grant Mechanism Engineering Research Centers (CPEs); Agreement BG E&P Brasil (Shell Group); Principal Investigator Kazuo Nishimoto; Investment R$16,027,741.80.

2. Numerical modeling and simulations applied to wind energy – Part of the HPCWE proposal submitted to call H2020-FETHPC-2018-2020 (nº 19/01507-8); Grant Mechanism Regular Research Grant; Agreement European Union (Horizon 2020); Principal Investigator Bruno Souza Carmo; Investment R$164,874.24.