Establishing the financial cost and environmental impact of work in advance is not a simple task for builders, engineers, and architects. Doing these calculations in real time, at the same time as developing the architectural project, and also recalculating the costs in accordance with changes to the design or material used, whether it is steel, wood, or concrete, is the proposal of the software being developed by São Paulo–based startup Archflex, founded by architects Taís de Moraes Alves and Fulvio Ramos Roxo.

The software, unprecedented in the world, is aimed at modular construction, a construction method in which the parts of the building (or modules) are standardized and produced in factories, and then simply assembled on site, providing greater agility to the process and reducing waste. The development of the program, still in prototype phase, has received support from FAPESP’s Innovative Research in Small Businesses (PIPE) program.

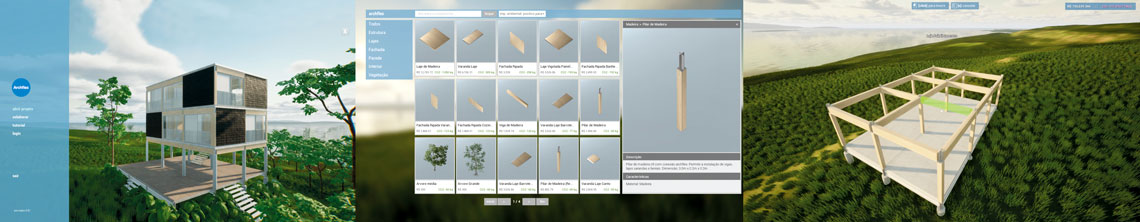

Using the tool, architects and engineers can create the architectural project accessing a library of parts available in the cloud and updated in real time by the suppliers. The platform also allows remote access by the end client, who can approve, reject, or suggest changes at each stage of the project and know the cost and carbon footprint of each suggested change immediately.

Although Alves and Roxo plan to present the software in the first half of 2023, their system has already sparked interest in Brazil and abroad. In 2022, the proposal led Alves to be one of the winners in the Early-Career Professionals category of the global competition Falling Walls Lab Brazil (FWL Brazil), the local stage of the competition of multidisciplinary ideas with high potential for environmental and social impact, currently promoted by the German Center for Research and Innovation (DWIH), of São Paulo, and by the Falling Walls Foundation.

In November last year, after making a pitch for the software in the final of the competition in Berlin, the architect took part in discussions with representatives from universities, research centers, and suppliers of construction modules from Germany, Switzerland, Austria, and Spain, countries where modular construction is highly developed.

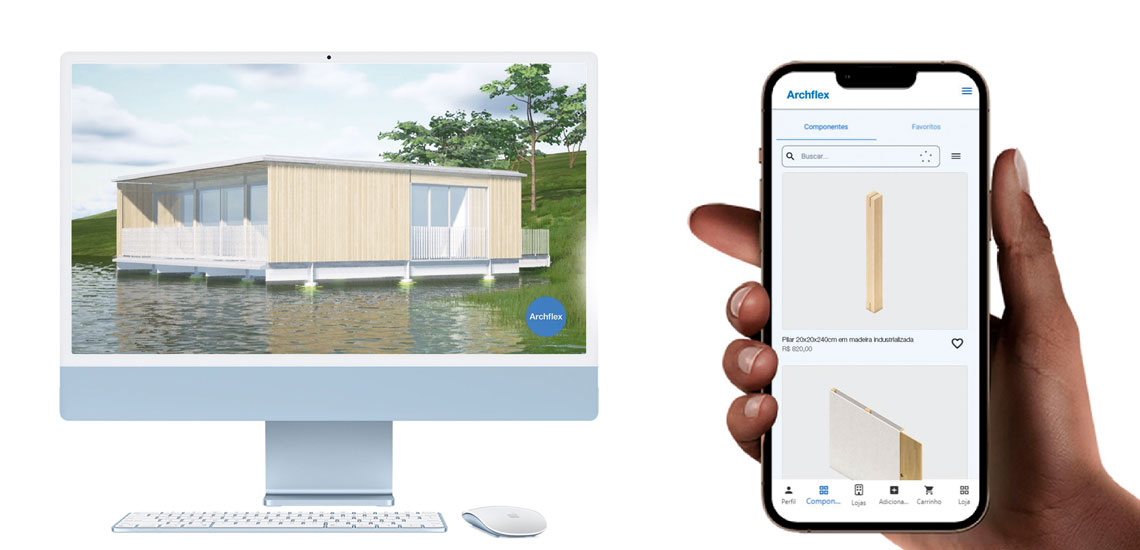

ArchflexThe projects can be accompanied in real time by the customer on a cellphone and computer screenArchflex

According to the architect, the new software’s friendly interface was one of the features that sparked international interest. “It’s a program that is really easy to use. It’s intuitive and immersive, and doesn’t require specific training,” describes Alves. The fact that the software had been created using gamification techniques also drew interest—in other words, it was inspired by the construction of online gaming programs, that are developed in such a way to allow the user to learn to manipulate the computational tools just through using it.

Additionally, the tool provides rendering of images of the project in real time. That is, realistic three-dimensional images are created of the work as the project is created, reproducing the effects of light and shadow and enabling, for example, to predict the effect of sunlight on a window and the lighting that should be generated in the environment. “For a layperson, it is much easier to understand the rendered project than viewing a technical drawing,” compares architect Milton Braga, from the School of Architecture and Urbanism at the University of São Paulo (FAU-USP) and consultant for Archflex.

Universal standards

In Brazil, the predominant construction method is the traditional one, using reinforced concrete and masonry, and modular systems are restricted to market niches. The luxury homes built in timber modules and generally assembled on the beach or in the countryside are a common example. Buildings made from steel and concrete modules are used more in commercial ventures, but they are also the minority. For Braga, the Archflex platform could boost modular construction in Brazil by enabling the end user to take part in the design of the project.

The construtech company’s software presupposes the possibility of combining technologies and materials from different suppliers. To do so, companies need to adopt open and compatible standards so that their modular components are interchangeable, i.e., the parts need to meet standards of size and format and use the same connection system, enabling, for example, that a slab from one supplier fits perfectly onto a beam from another and a panel of a third supplier. In the same way, windows, doors, or roofs can come from any manufacturer depending on the consumer’s preference.

Getting companies to adopt universal standards is one of the main challenges for the success of the Archflex proposal. In Brazil, many manufacturers of modules choose their own solutions, a system in which they supply a complete package, including the design, all the parts and the execution of the work. “It’s the main strategy, but this is a culture in transformation. More and more companies, especially large suppliers of raw materials, are interested in open standards that can spread modular construction,” says Roxo. “We have already held conversations with several companies interested in open standards.”

The core of the discussions for a national strategy for the open standardization of components takes place within the scope of the Modular Construction Alliance, an institution that joins 43 participants including companies from the steel, wood panel, and concrete industries, engineering and architecture firms, and startups. The Alliance is linked to the Center of Innovation in Sustainable Construction (CICS) of the USP Polytechnic School (POLI), the startup accelerator HousingPact, and to the Innovation and Digital Construction Hub (HUBIC), an initiative of USP and the Brazilian Association of Portland Cement (ABCP).

ArchflexThe startup intends to create a marketplace with all the parts used in their modular constructionsArchflex

“Companies from the industrial sector need scale to be viable. A system with open standards, in which the components produced by different companies can be interchanged, is the only strategy with potential to boost the Brazilian productive chain of modular construction,” stresses civil engineer Vanderley John, a member of the management team at CICS. “Our proposal is that the Modular Construction Alliance seek to develop open standards. In this scenario, the Archflex software could be the great facilitator of the development of Brazilian modular construction, particularly if the platform evolves into a marketplace,” says the professor from POLI.

The idea of a marketplace—or a virtual shopping mall—for modular construction, enabling the software user to complete the approval of the project with the online acquisition of modular components, is one possibility of the business model being studied by the entrepreneurs at Archflex. If it goes ahead, the company will not need to charge for using the software, and will be remunerated through sales in the online mall.

“It is where we are planning to reach. The companies that make up the Modular Construction Alliance will be invited to offer their products and be part of the initial configuration of the marketplace. Then we intend to cover suppliers of paint, finishing parts, and landscaping,” adds Ramos Filho.

Another challenge the startup still needs to overcome is perfecting the calculation of the carbon footprint for projects developed on the tool. The first step will be to automate the integration of the software with reliable databases, as is the case of the Information System for the Environmental Performance of Construction (SIDAC), which allows the calculation of the environmental performance of components based on Brazilian data and on Life Cycle Assessment (LCA) concepts. In the future, the software will have to include Georeferencing data of suppliers and sites, in order to account for the emissions associated with the transport of inputs in the project’s carbon footprint calculation.

The original proposal that led to the formation of Archflex was to develop an industrialized timber modular construction system for buildings up to five stories, accessible to the urban middle class, and for commercial enterprises; an idea that remains on the horizon for the company, but with no commercial launch planned.

The software gained importance in Archflex’s development plan after partners Alves and Roxo took part in FAPESP’s Training Program in High-Tech Entrepreneurship (PIPE-Empreendedor) and, also, due to conversations with professionals and suppliers. “We realized that society’s real need was not another construction module factory, but a way of integrating the already existing modules and, therefore, expanding the market,” explains Roxo. The finding led to the conviction of the need for open standards for modules and to the idea of the software to enable the exchange of technologies and suppliers.

Projects

1. Archflex: Construction system for buildings made of engineered wood (no. 21/04802-0); Grant Mechanism Innovative Research in Small Businesses (PIPE); Principal Investigator Taís de Moraes Alves (USP); Investment R$933,044.25.

2. Archflex: Industrialized system of flexible wooden modules (no. 18/22343-0); Grant Mechanism Innovative Research in Small Businesses (PIPE); Principal Investigator Taís de Moraes Alves (USP); Investment R$143,544.40.